Method for preparing negative electrode material mono-dispersed nano-crystalline lithium titanate by using nanometer microreactor

A microreactor, anode material technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the degradation of electrochemical performance of materials, dendrite short circuit, electrolyte consumption and first Coulomb efficiency Low problems, to achieve the effect of improving electrochemical performance and preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] For 0.05mol monodisperse TiO 2 Coating with oleic acid makes each monodisperse TiO 2 The particles were evenly coated with oleic acid; 0.1mol TEOS was added to the water / ethanol (volume ratio 1:0.1) solution containing cetyltrimethylammonium bromide surfactant; the TiO coated with oleic acid 2 Dispersed in the above solution, TEOS undergoes hydrolysis and condensation reactions at the oil-water / ethanol interface to form hollow TiO 2 SiO 2 core-shell structure; the hollow TiO 2 SiO 2 The core-shell structure is fully mixed with lithium acetate, and calcined at 800°C to form Li 4 Ti 5 o 12 Li 2 SiO 3 ; Will Li 4 Ti 5 o 12 Li 2 SiO 3 Dissolved in hot NaOH solution, finally forming monodisperse nanocrystalline Li 4 Ti 5 o 12 . Hollow mesoporous silica spheres as nano-microreactors not only prevent Li 4 Ti 5 o 12 Agglomeration occurs, and provides lithium acetate diffusion and TiO 2 Air holes reacting in hollow spheres; figure 1 monodisperse nanocrystal...

Embodiment 2

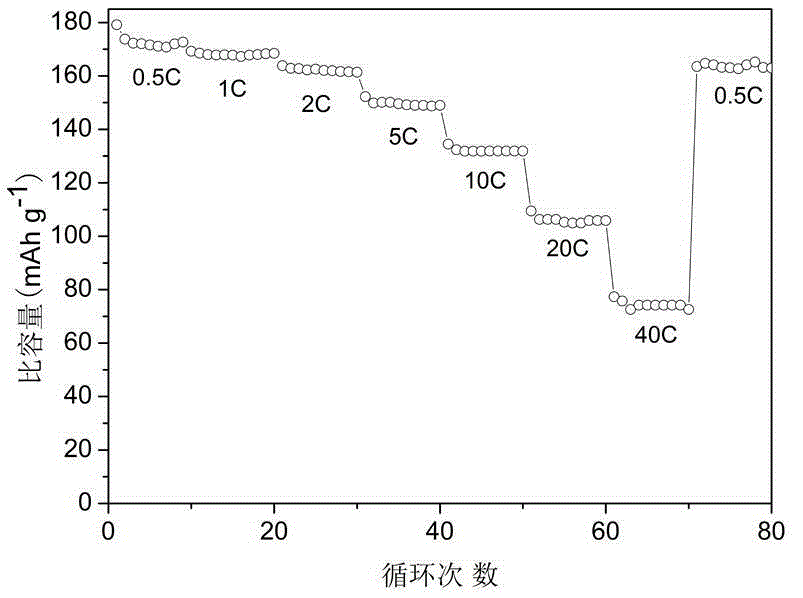

[0024] For 0.05mol monodisperse TiO 2 Coating with linoleic acid makes each monodisperse TiO 2 The particles were uniformly coated with linoleic acid; 0.1mol TEOS was added to the water / ethanol (volume ratio 1:0.5) solution containing dodecyldimethylamine oxide surfactant; the TiO coated with linoleic acid 2 Dispersed in the above solution, TEOS undergoes hydrolysis and condensation reactions at the oil-water / ethanol interface to form hollow TiO 2 SiO 2 core-shell structure; the hollow TiO 2 SiO 2 The core-shell structure is fully mixed with lithium nitrate, and calcined at 900°C to form Li 4 Ti 5 o 12 Li 2 SiO 3 ; Will Li 4 Ti 5 o 12 Li 2 SiO 3 Dissolved in hot NaOH solution, finally forming monodisperse nanocrystalline Li 4 Ti 5 o12 . figure 2 for Li 4 Ti 5 o 12 The charge-discharge curves of the material at different rates of 1-40C. It can be seen from the figure that the synthesized material has an excellent charge-discharge platform and high reversible...

Embodiment 3

[0026] For 0.05mol monodisperse TiO 2 Coating with lauric acid makes each monodisperse TiO 2 The particles were uniformly coated with lauric acid; 0.1mol TEOS was added to the water / ethanol (volume ratio 1:0.5) solution containing dodecyldimethylamine oxide surfactant; the TiO coated with lauric acid 2 Dispersed in the above solution, TEOS undergoes hydrolysis and condensation reactions at the oil-water / ethanol interface to form hollow TiO 2 SiO 2 core-shell structure; the hollow TiO 2 SiO 2 The core-shell structure is fully mixed with lithium nitrate, and calcined at 1000°C to form Li 4 Ti 5 o 12 Li 2 SiO 3 ; Will Li 4 Ti 5 o 12 Li 2 SiO 3 Dissolved in hot NaOH solution, finally forming monodisperse nanocrystalline Li 4 Ti 5 o 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com