Colored noctilucent rubber tire mark, preparation method thereof, die and tire

A rubber tire and color film technology, applied in the directions of illuminated markings, instruments, display devices, etc., can solve the problem of the influence of the luminous effect of the luminous tire mark, restricting the application of the color luminous rubber tire mark, and high cost, so that the tire mark is clearly visible. , the display effect is good, the effect of improving the flexural resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

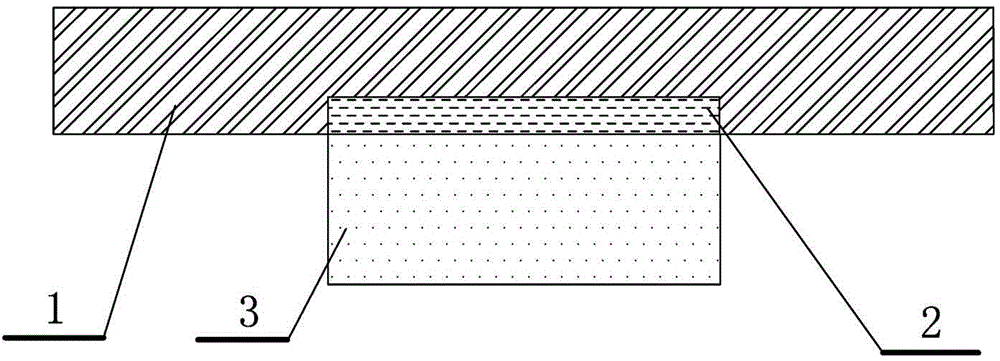

[0045] Such as figure 1 As shown, a color luminous rubber tire label, the colored luminous rubber tire label includes an upper layer of color luminous film and a lower layer of bottom rubber film 1, and the color luminous film is composed of an upper layer of luminous film 2 and a lower layer of color film 3. The color film 3 is embedded in the primer film 1 , the surface of the luminous film 2 is higher than the primer film 1 , and the luminous film 2 protrudes from the surface of the primer film 1 . The height of the luminous film 2 protruding from the surface of the primer film 1 is 0.3-0.5 mm. The thickness of the color luminous rubber tire label is 0.5-1.0 mm, the thickness of the primer film 1 is 0.2-0.5 mm, the thickness of the color luminous film is 0.4-0.6 mm, and the thickness of the luminous film 2 is 0.3-0.5 mm. mm, the thickness of the color film 3 is 0.1-0.5mm.

[0046] The primer film 1 is made of black rubber, and the luminous film 2 includes transparent rubb...

Embodiment 2

[0063] This embodiment is an improvement made on the basis of Embodiment 1. For the same part as Embodiment 1 in this embodiment, please refer to the content disclosed in Embodiment 1 for understanding, and the content disclosed in Embodiment 1 should also be used as this embodiment. The content of the example will not be repeated here. The formula for the transparencies is:

[0064] Raw material formula

[0065] Natural rubber 10.00

[0066] SBR 65.00

[0067] Butadiene rubber 35.00

[0068] Luminous powder 20.00

[0069] White carbon black (particle size ≤ 15μm) 30.00

[0070] Calcium Carbonate 25.00

[0071] Zinc oxide (transparent) 3.00

[0072] Stearic acid 5.00

[0073] Ethylene glycol 2.00

[0074] Antiaging agent CP-C2.00

[0075] Antiaging agent MB3.00

[0076] Accelerator DM0.60

[0077] Accelerator H0.60

[0078] Accelerator TMTD1.00

[0079] Accelerator PX1.00

[0080] Sulfur 2.00

[0081] Softener 12.00

Embodiment 3

[0083] A method for making a colored luminous rubber tire label, comprising the following steps:

[0084] 1) Calender the color rubber material with a calender to make a color film;

[0085] 2) Calender the primer material with a calender to make a primer film;

[0086] 3) Calender the luminous rubber material with a calender to make a luminous film;

[0087] 4) Composite color film and luminous film with calender to make color luminous film;

[0088] 5) Press and vulcanize the color luminous film and the base rubber film through a mold to make a color luminous rubber tire label;

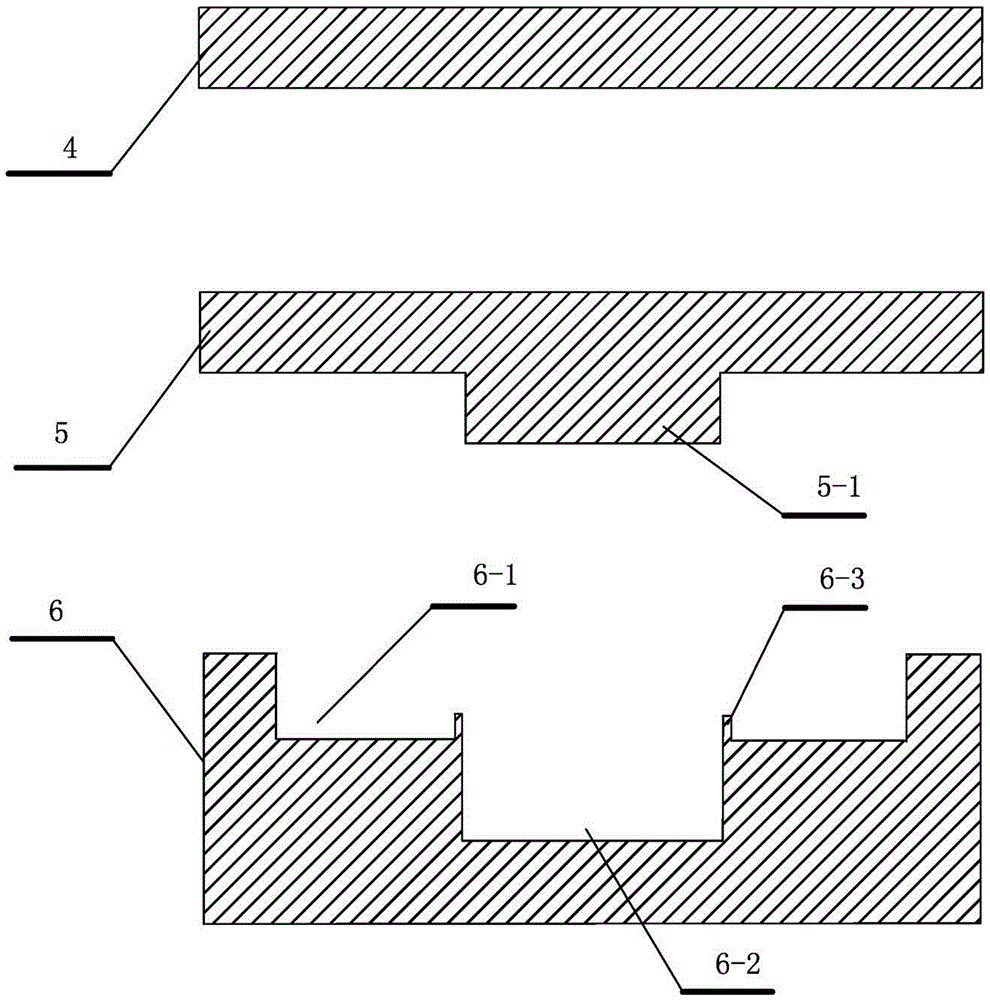

[0089] Cover the lower plate of the mold with the color luminous film, cover the middle plate for pressing the pattern, close the mold and vulcanize for 2 to 4 minutes, open the mold, tear off the remaining glue to retain the required color luminous adhesive pattern; remove the middle plate , cover the bottom rubber film on the lower plate of the mold, cover the upper plate, close the mold and vu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com