Gas-sensor nanometer sensitive material, slurry with gas-sensor nanometer sensitive material, preparing method of gas-sensor nanometer sensitive material, preparing method of slurry and application of gas-sensor nanometer sensitive material

A gas sensor, sensitive material technology, applied in nanotechnology, analytical materials, nanotechnology and other directions, can solve the problems of consistency, poor repeatability, uneven film thickness, cracking of the coating layer, etc., to achieve easy mass production, The effect of high sensitivity and enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

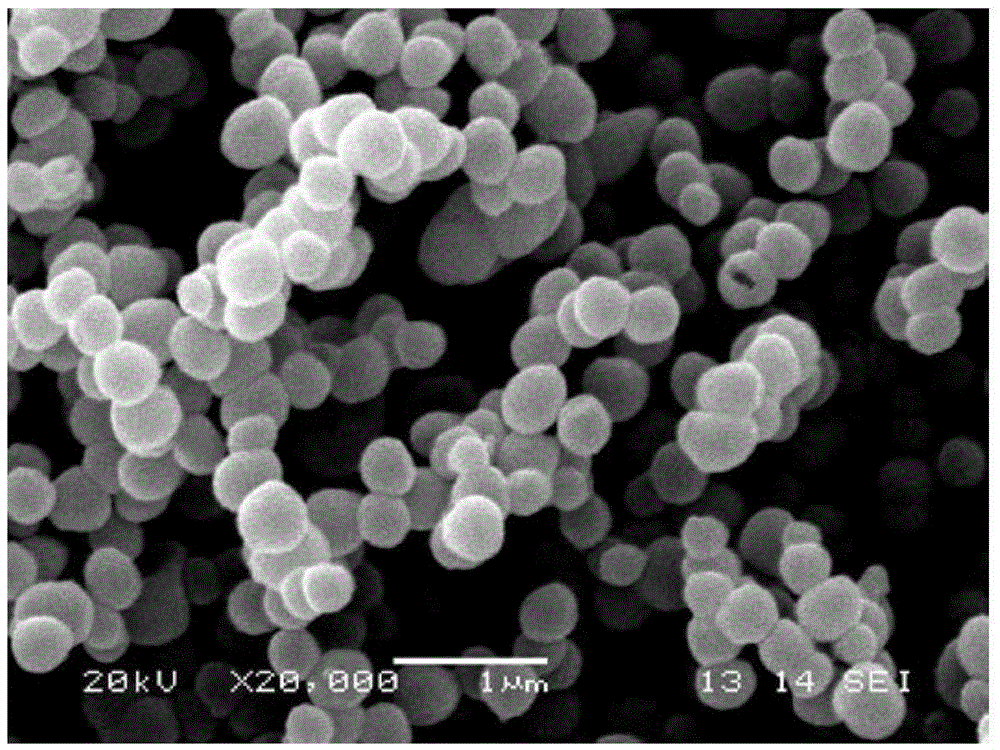

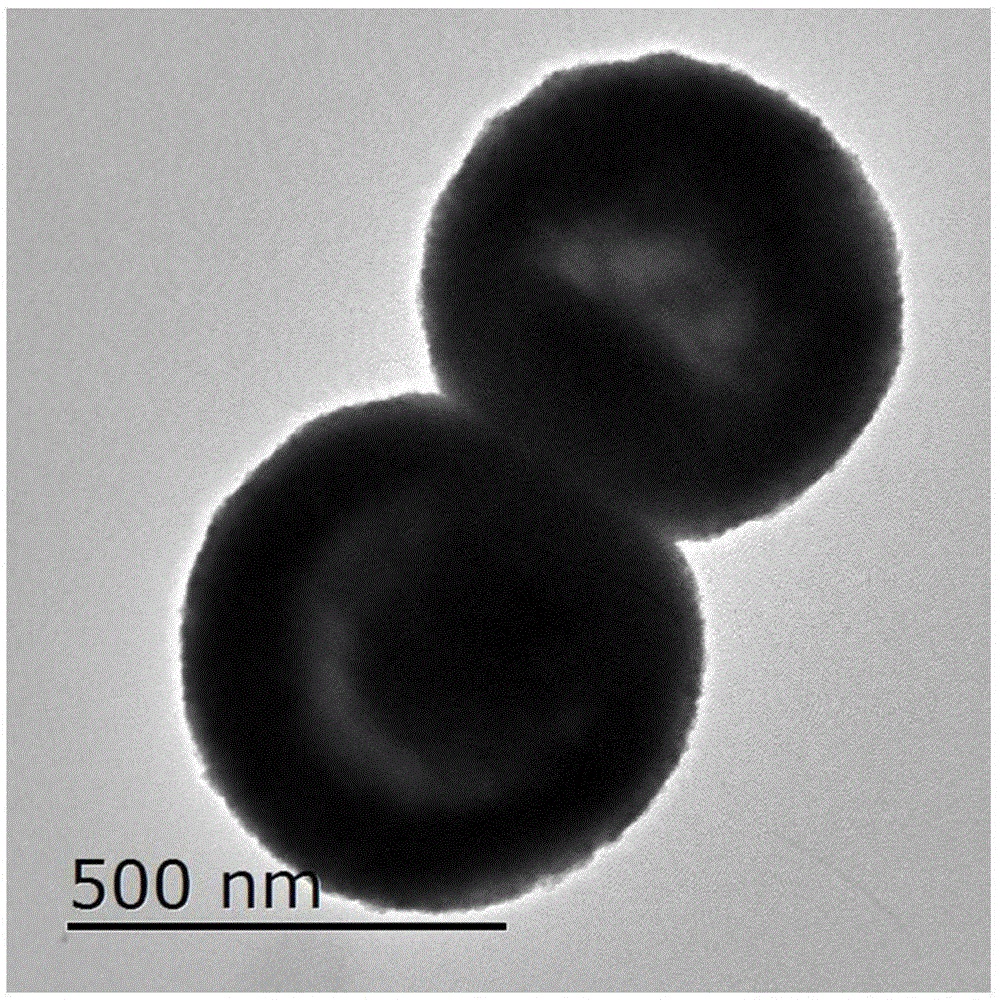

[0040] Add sodium stannate to ultrapure water, ultrasonically disperse for 5 minutes to obtain a 0.01mol / L transparent homogeneous aqueous solution, add ultrasonically dispersed 0.05mol / L urea ethanol solution, the volume ratio of the two is 1:1, and continue to ultrasonically mix After 10 minutes, the obtained mixed solution was transferred to a hydrothermal reaction kettle, and reacted at 120°C for 12h. After the reaction was completed, it was cooled to room temperature, and the sediment at the bottom was collected, washed by centrifugation, and dried in an oven at 60°C for 24h to finally obtain nano-SnO 2 hollow ball.

[0041] The nano-SnO obtained after drying 2 Hollow sphere powder, add distilled water and ultrasonically disperse for 15min, add Pd(NO 3 ) 2 solution, Pd(NO 3 ) 2 with SnO 2 The mass ratio of the solution is 1:100, add ammonia water to the pH of the mixed solution = 9, stir at room temperature for 12 hours, centrifuge to collect the bottom precipitate, ...

Embodiment 2

[0048] Add potassium stannate to ultrapure water, and ultrasonically disperse for 10 minutes to obtain a 0.02mol / L transparent homogeneous aqueous solution, add ultrasonically dispersed 0.1mol / L urea ethanol solution, the volume ratio of the two is 1.8:1, and continue to ultrasonically mix After 15 minutes, the obtained mixed solution was transferred to a hydrothermal reaction kettle, and reacted at 150°C for 24h. After the reaction was completed, it was cooled to room temperature, and the sediment at the bottom was collected, washed by centrifugation, and dried in an oven at 80°C for 12h to finally obtain nano-SnO 2 hollow ball.

[0049] The nano-SnO obtained after drying 2 Hollow sphere powder, add distilled water and ultrasonically disperse for 20min, add Pd(NO 3 ) 2 solution, Pd(NO 3 ) 2 with SnO 2 The mass ratio of the solution is 2:100, adding ammonia water to the pH of the mixed solution = 10, stirring at room temperature for 24 hours, centrifuging to collect the b...

Embodiment 3

[0057] Add potassium stannate to ultrapure water, and ultrasonically disperse for 20 minutes to obtain a 0.04mol / L transparent homogeneous aqueous solution, add ultrasonically dispersed 0.4mol / L urea ethanol solution, the volume ratio of the two is 3:1, and continue to ultrasonically mix After 20 minutes, the obtained mixed solution was transferred to a hydrothermal reaction kettle, and reacted at 180°C for 24h. After the reaction was completed, it was cooled to room temperature, and the sediment at the bottom was collected, washed by centrifugation, and dried in an oven at 80°C for 12h to finally obtain nano-SnO 2 hollow ball.

[0058] The nano-SnO obtained after drying 2 Hollow sphere powder, add distilled water and ultrasonically disperse for 20min, add Pd(NO 3 ) 2 solution, Pd(NO 3 ) 2 with SnO 2 The mass ratio of the solution is 2:100, adding ammonia water to the pH of the mixed solution = 10, stirring at room temperature for 24 hours, centrifuging to collect the bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com