Device and method for measuring heat conductivity coefficient reduction rate of concrete in uniaxial compression process

A technology of thermal conductivity and uniaxial compression, which is applied in the field of concrete construction, can solve the problems of uncertain location and number of cracks, achieve small size, reduce contact thermal resistance, and ensure integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific examples.

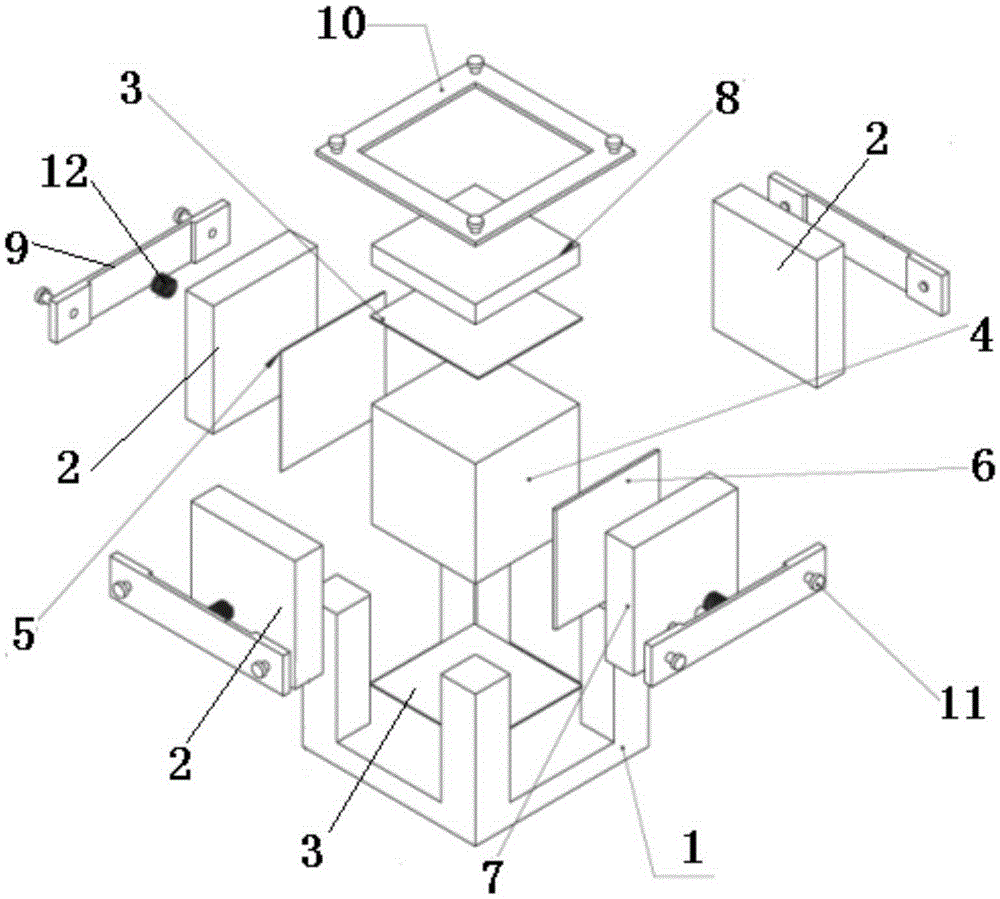

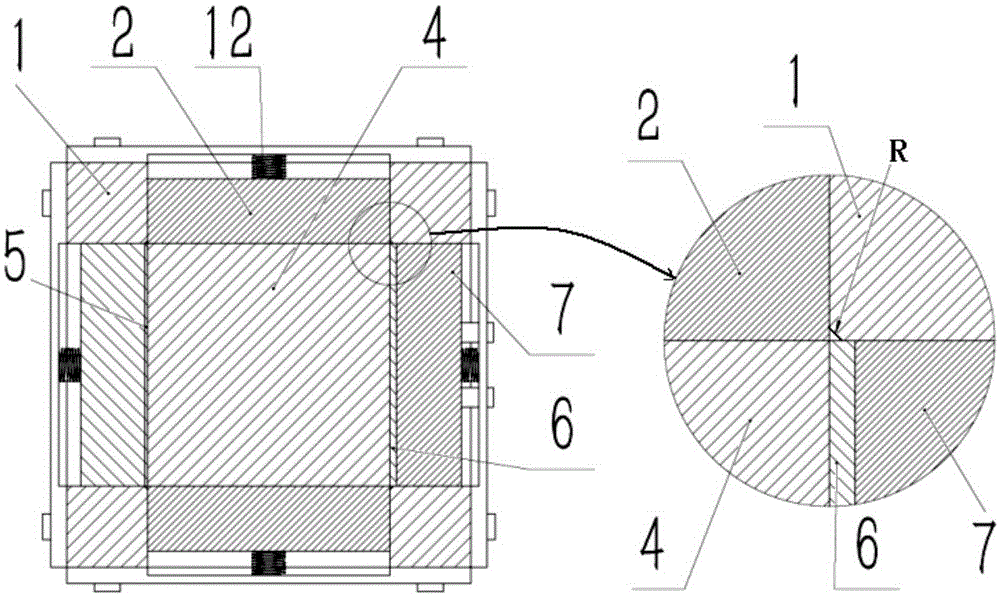

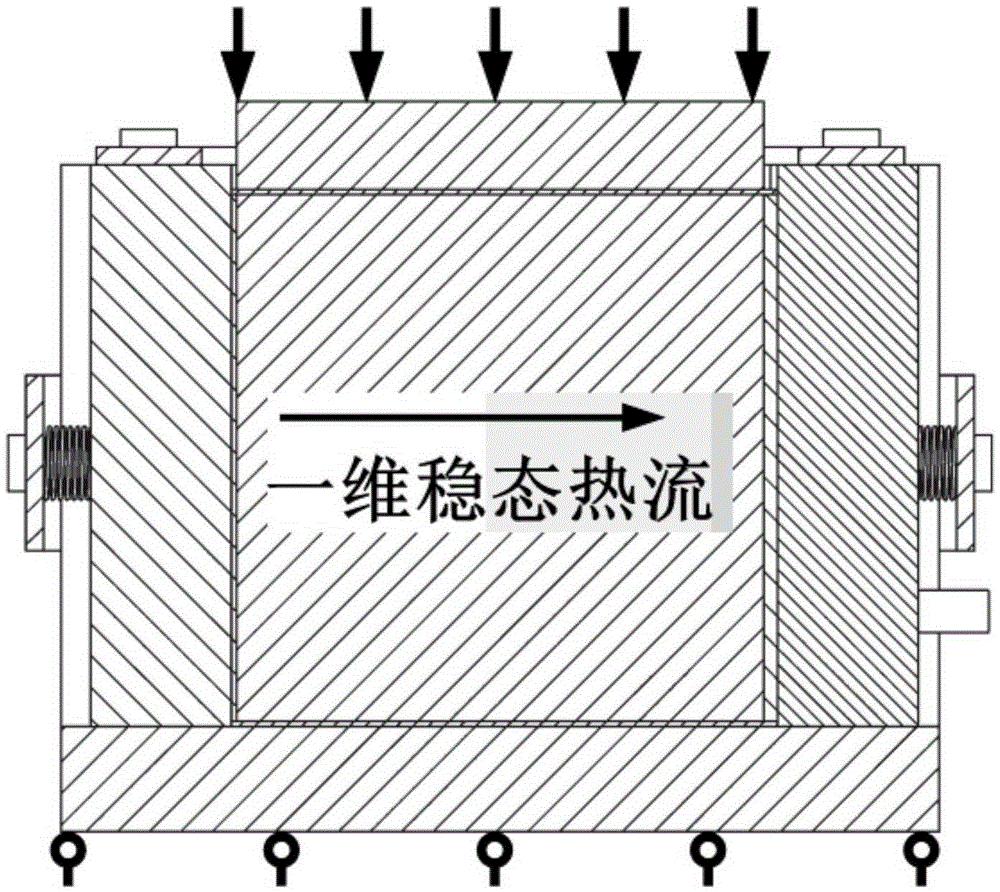

[0040] like figure 1 and figure 2 As shown, a device for measuring the decrease rate of concrete thermal conductivity during uniaxial compression, including a bracket 1, an insulating foam board 2, asbestos cloth 3, a heating unit 5, a heat-conducting silica gel 6, a refrigeration unit 7, a pressing plate 8, a spring pressing plate 9, Bracket upper frame 10, screw 11, spring 12;

[0041] Bracket 1 is placed on the supporting platform of the testing machine, concrete specimen 4 is placed in the center of bracket 1, and asbestos cloth 3 is placed on the contact surface between the bottom of concrete specimen 4 and support 1; a pair of parallel surfaces of concrete specimen 4 is selected and placed on one side A heating unit 5 and an insulating foam board 2 are embedded between the pillars, a heat-conducting silica gel 6 and a refrigeration unit 7 are embedded on the other sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com