Cone valve type dynamic visualization achieving device and method for high-pressure fuel oil system of diesel engine

A high-pressure fuel oil and diesel engine technology, applied in the direction of fuel injection devices, measuring devices, charging systems, etc., can solve the problems of reduction, valve shock vibration, lack of experimental basis and theoretical analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

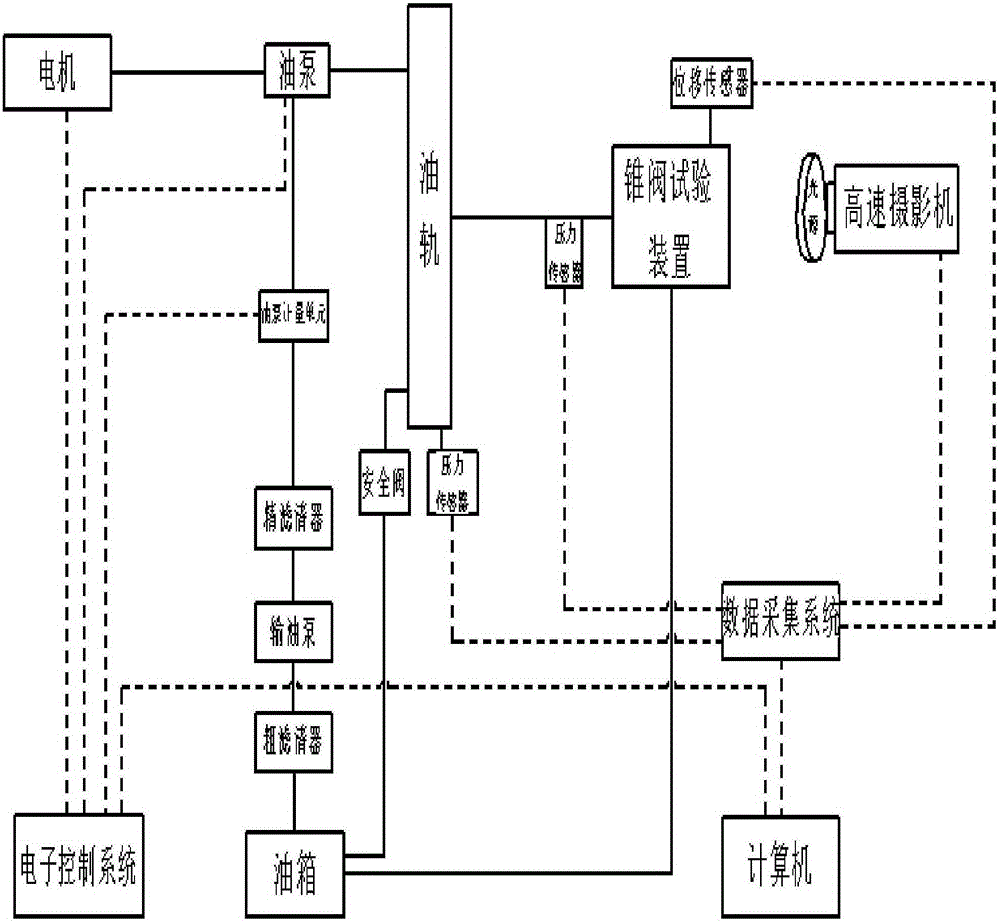

[0020] Such as figure 1 As shown, a schematic diagram of the realization method of the dynamic visualization device of the cone valve of the high-pressure fuel system of the diesel engine, including the electronic control system, the drive motor, the oil pump, the oil rail, the metering unit of the oil pump, the safety valve, the cone valve test device, the camera, the light source, the data Acquisition system and computer.

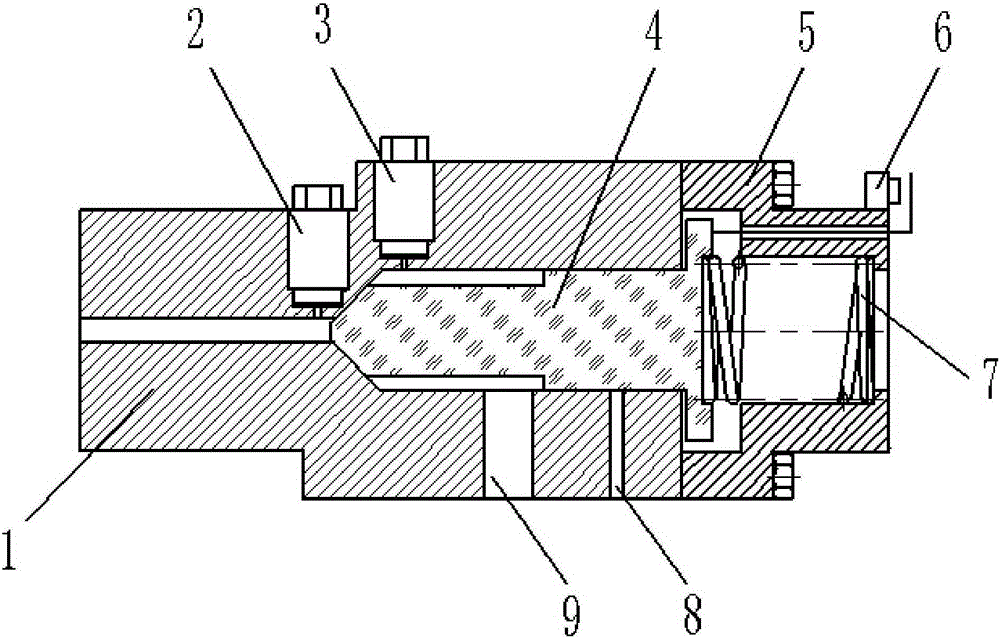

[0021] Such as figure 2 As shown, a device for realizing dynamic visualization of a cone valve in a high-pressure fuel system of a diesel engine, including a cone valve body (1), an inlet pressure sensor (2), an outlet pressure sensor (3), a valve core (4), and a compression cover (5) , displacement sensor (6), spring (7).

[0022] The cone valve body (1) is metal with a cone valve flow channel inside; the valve core (4) is made of optical glass and can move freely in the flow channel; the valve body (1) and valve core (4) The matching cone surface wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com