Split stationary blade of steam turbine having small crown structure and machining method thereof

A processing method and steam turbine technology, which can be applied to mechanical equipment, engine components, machines/engines, etc., can solve problems such as increasing production processes, and achieve the effect of saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

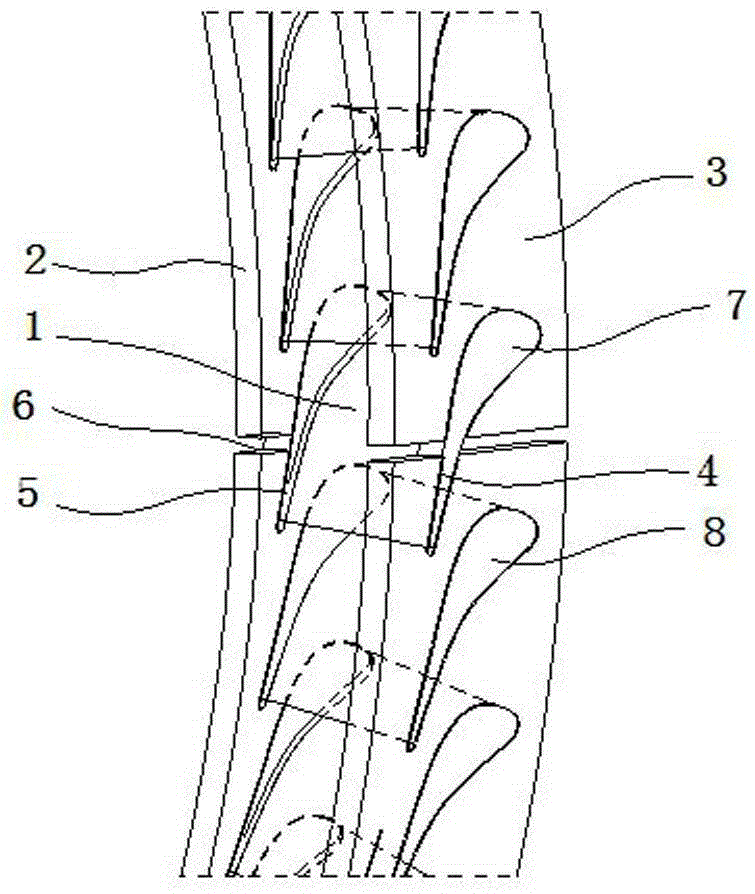

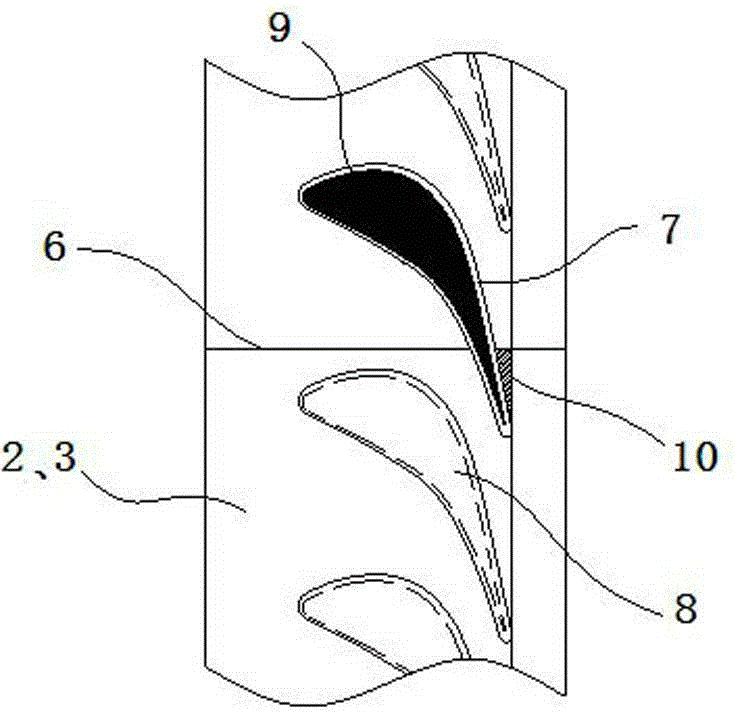

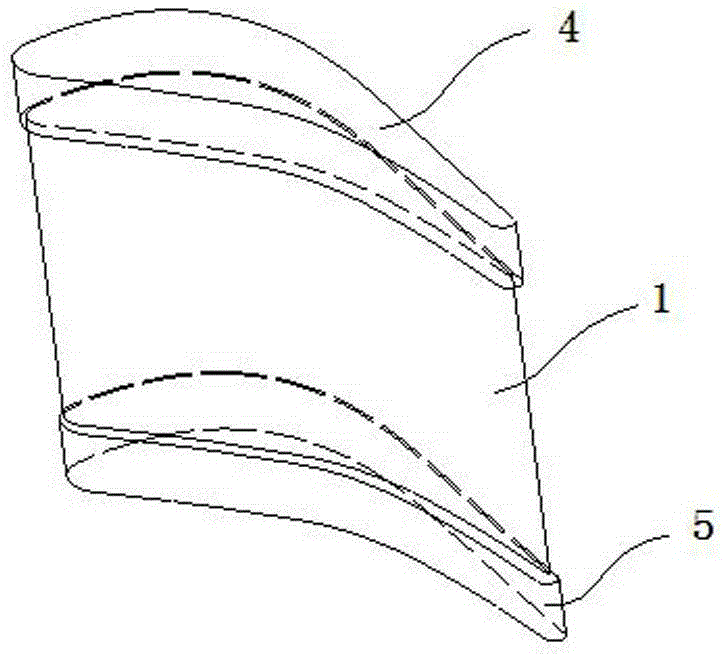

[0019] Such as Figure 1 to Figure 4 Shown: a steam turbine with a small shroud structure, including a blade body 1, a crown 4 and a bottom shroud 5, the blade body 1 is located below the top shroud 4 and the bottom shroud 5 according to the dividing line of the middle split plane 6 A part is machined away in the direction of the steam passage at each place, and this part is not more than 1 / 4 of the length of the airfoil, and the width is 3mm, so that the airfoil 1 of this part does not enter the hole 9. Actually, the standard stationary blade 8 is cut according to the above requirements.

[0020] A method for processing the faceted stator vane in the above-mentioned steam turbine with small crown structure, comprising the following steps:

[0021] 1) Find the position of the dividing line 6 of the horizontal mid-section plane on the stationary blade 7 of the mid-section plane; mark the positions with lines on the crown 4 and bottom crown 5 respectively;

[0022] 2) Cut off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com