Printing and dyeing auxiliary agent, and preparation method and application thereof

A technology of printing and dyeing auxiliaries and polyoxyethylene diamine, which is applied in the field of printing and dyeing, can solve problems such as complex components, achieve the effect of meeting work needs, broad industrialization prospects and market value, and improving color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

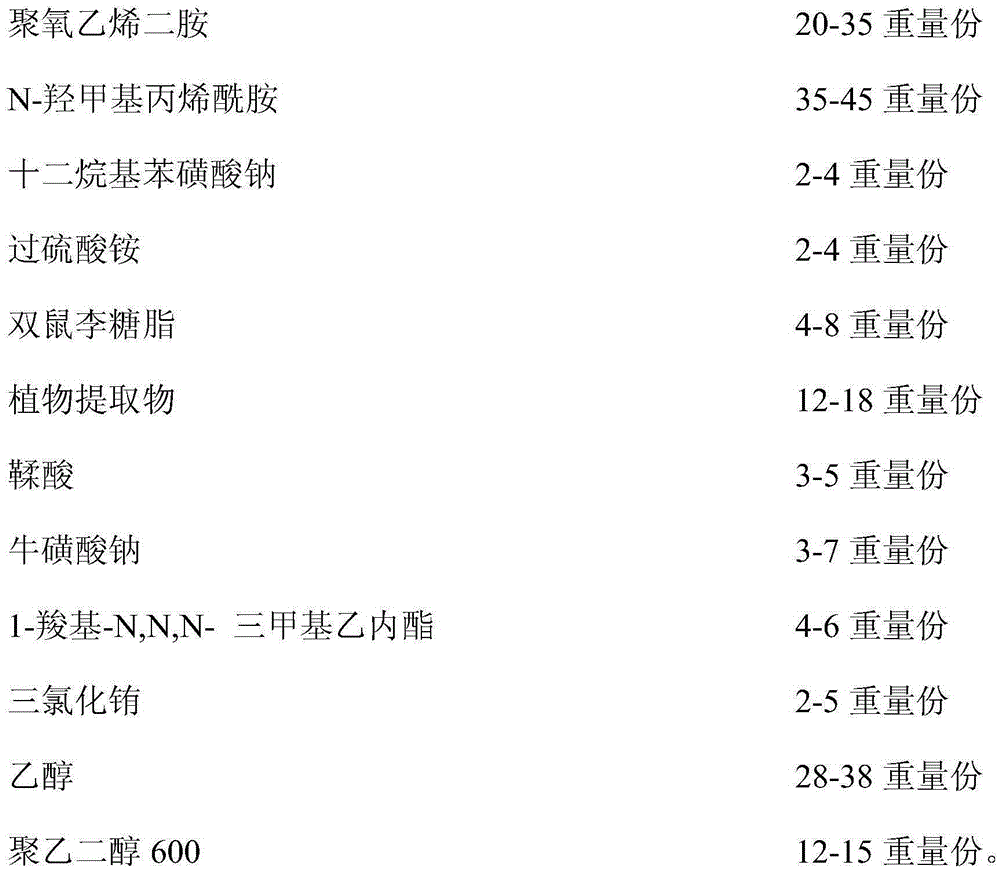

Method used

Image

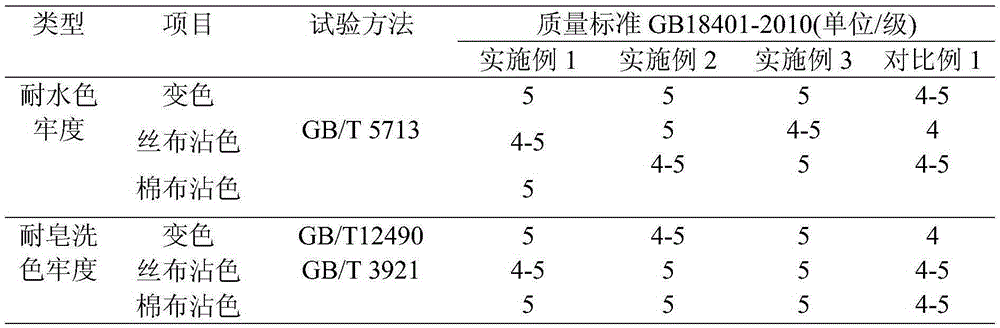

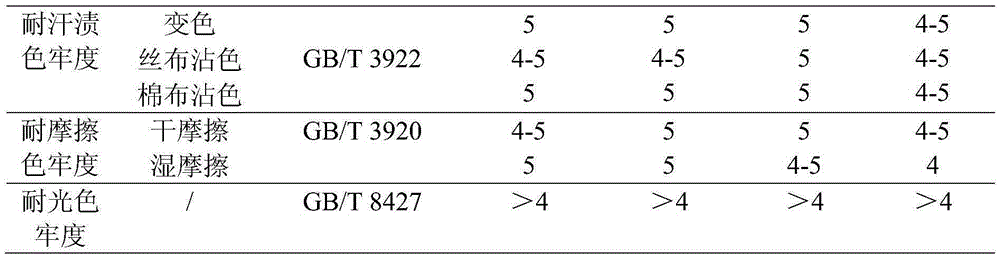

Examples

preparation example Construction

[0029] Preparation of plant extracts

[0030] Weigh 200g of camphor leaves, white orchids and Chuanqiong respectively, add 2000g of water to soak overnight, then add 1200g of ethanol, extract at a microwave power of 150W for 50min, after the extraction is complete, filter and concentrate the filtrate to 1 / 30 of the volume, then freeze After drying, camphor leaf extract, white orchid extract and Chuanqiong extract can be obtained respectively, and mixed at a mass ratio of 1:1:1 to obtain the plant extract of the present invention.

Embodiment 1

[0032] (1) 20 parts by weight of polyoxyethylene diamine, 40 parts by weight of N-methylolacrylamide, 4 parts by weight of sodium dodecylbenzenesulfonate and 17 parts by weight of plant extract Put the material into the reaction kettle and stir evenly, raise the temperature to 115°C, add 2 parts by weight of ammonium persulfate, keep the temperature for 1.5h, cool down to 55°C to obtain the reaction solution;

[0033] (2) 6 parts by weight of dirhamnolipid, 5 parts by weight of tannic acid, 3 parts by weight of sodium taurate, 5 parts by weight of 1-carboxy-N, N, N-trimethylbetaine and 30 parts by weight Add ethanol to the above reaction solution in turn, raise the temperature to 70°C and continue stirring for 0.5h to obtain a mixed solution;

[0034] (3) Add 2 parts by weight of europium trichloride and 12 parts by weight of polyethylene glycol 600 to the above mixed solution, stir and disperse at room temperature for 20 minutes, and then ultrasonicate for 20 minutes at an ul...

Embodiment 2

[0036] (1) 35 parts by weight of polyoxyethylene diamine, 35 parts by weight of N-methylolacrylamide, 2 parts by weight of sodium dodecylbenzenesulfonate and 12 parts by weight of plant extract After putting the material into the reaction kettle and stirring evenly, the temperature was raised to 110°C, 3 parts by weight of ammonium persulfate was added, the temperature was kept for 2 hours, and the temperature was lowered to 60°C to obtain the reaction solution;

[0037] (2) 8 parts by weight of dirhamnolipid, 3 parts by weight of tannic acid, 7 parts by weight of sodium taurate, 4 parts by weight of 1-carboxy-N, N, N-trimethylbetaine and 28 parts by weight Ethanol was sequentially added to the above reaction solution, the temperature was raised to 75°C and stirring was continued for 1 h to obtain a mixed solution;

[0038] (3) Add 5 parts by weight of europium trichloride and 14 parts by weight of polyethylene glycol 600 to the above mixed solution, stir and disperse at room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com