Novel lubricating grease for weaving machine and preparation method of novel lubricating grease

A lubricating grease and technology for looms, applied in the field of new lubricating grease for looms and its preparation, can solve problems such as poor fluidity, short lubrication life, reduced fluidity and versatility of lubricating grease, and achieve simple preparation method and good performance Effect of stability, good lubrication and antiwear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Weigh 70kg of 100# engine oil, 6kg of polyvinyl alcohol, 4kg of epoxy acrylic acid, 3kg of bornyl isovalerate, 3kg of hydroxymethylcellulose, 1kg of citronellal, 0.5kg of dimethylolurea, 4- Guanidinobutyric acid 0.5kg, isooctyl dimercaptoacetate di-n-octyltin 0.2kg and succinic acid 0.02kg, mix well;

[0031] (2) Add to a high-pressure homogenizer and mix for 10 minutes at 80° C. under a pressure of 20 MPa, adjust the pH to 7.4, and obtain lubricating grease for looms.

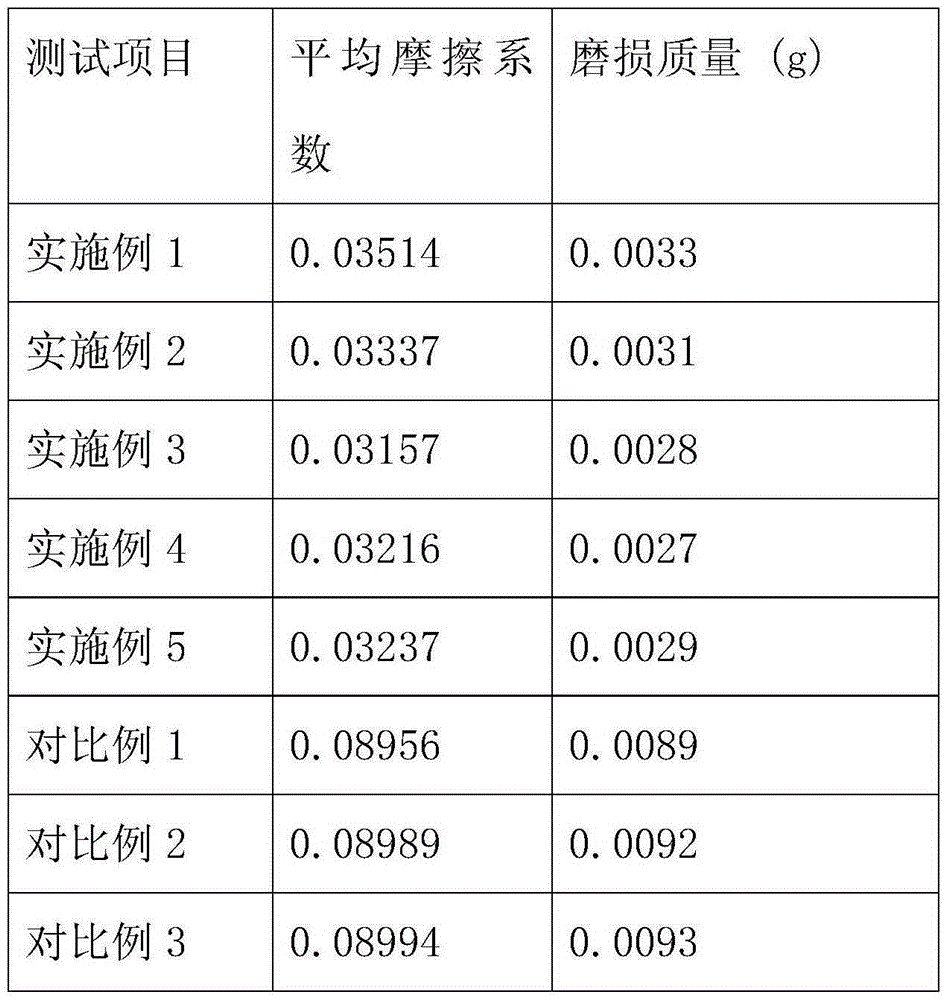

[0032] The performance test results of the prepared lubricating grease for looms are shown in Table 1.

Embodiment 2

[0034] (1) Weigh 70kg of 100# engine oil, 6kg of polyvinyl alcohol, 4kg of epoxy acrylic acid, 3kg of bornyl isovalerate, 3kg of hydroxymethylcellulose, 1kg of citronellal, 0.5kg of dimethylolurea, 4- Guanidinobutyric acid 0.5kg, isooctyl dimercaptoacetate di-n-octyltin 0.2kg, succinic acid 0.02kg and zinc borate 0.3kg, mix well;

[0035] (2) Add to a high-pressure homogenizer and mix for 10 minutes at 80° C. under a pressure of 20 MPa, adjust the pH to 7.4, and obtain lubricating grease for looms.

[0036] The performance test results of the prepared lubricating grease for looms are shown in Table 1.

Embodiment 3

[0038] (1) Weigh 85kg of 68# rail oil, 8kg of polyvinyl alcohol, 6kg of epoxy acrylic acid, 5kg of bornyl isovalerate, 5kg of hydroxymethylcellulose, 1kg of citronellal, 0.5kg of dimethylolurea, 4 - 0.8kg of guanidinobutyric acid, 0.4kg of isooctyl dimercaptoacetate di-n-octyltin, 0.8kg of succinic acid and 0.3kg of zinc borate, mixed uniformly;

[0039] (2) adding to a high-pressure homogenizer at 100° C. and mixing for 20 minutes under a pressure of 18 MPa, and adjusting the pH to 7.8 to obtain lubricating grease for looms.

[0040] The performance test results of the prepared lubricating grease for looms are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com