Resistance type crane safety device capable of preventing aslant pulling and hanging

A technology of safety devices and cranes, which is applied in the directions of safety devices, transportation and packaging, and load hanging components, etc., which can solve problems such as accidents, collisions with people or objects, and damage to rope arrangement devices, and achieve easy manufacturing, installation, use, and structure The effect of simple, good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

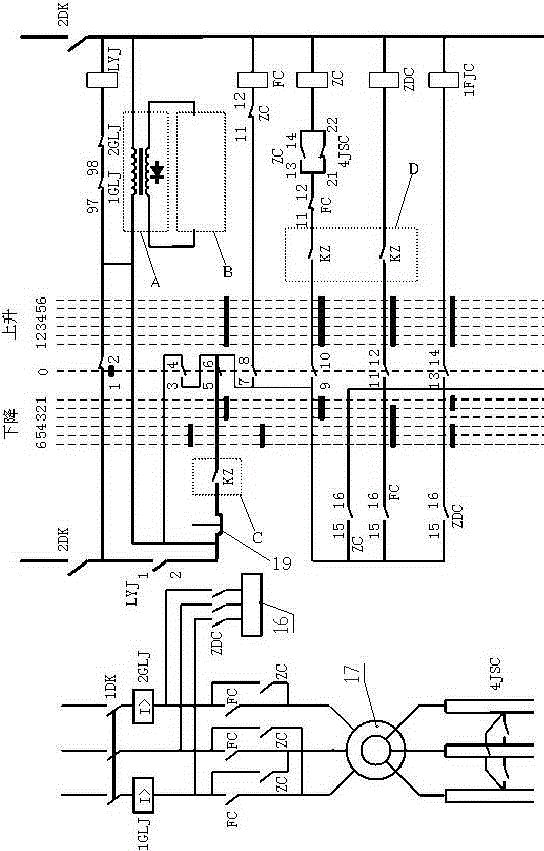

[0030] image 3 and Figure 4 Among them, 1DK is the power circuit switch; 2DK is the control circuit switch; 1GLJ and 2GLJ are overcurrent contactors; ZDC is the brake contactor; ZC is the rising direction contactor; FC is the falling direction contactor; Resistance contactor; FWL is a sliding rheostat mechanism formed by connecting wire 8, rheostat disc and sliding contact; KZ is a control contactor.

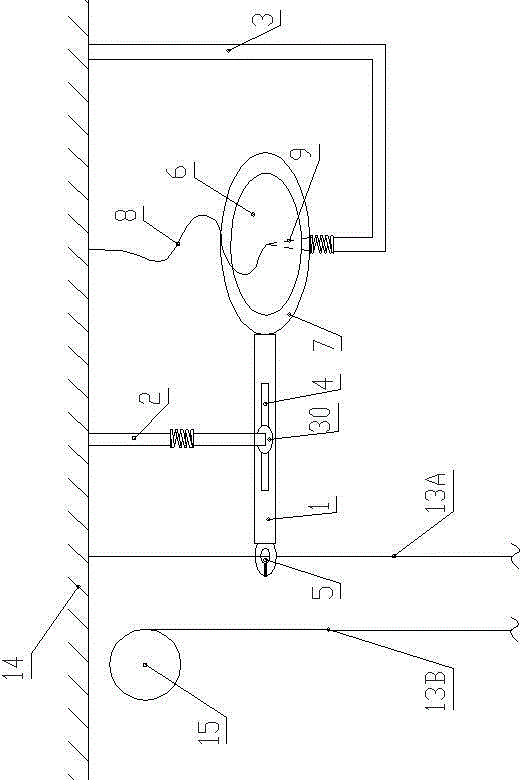

[0031] figure 1 Among them, the symbol 13A shows the hoisting wire rope on one side of the stationary end, and the symbol 13B is the hoisting wire rope on the other side.

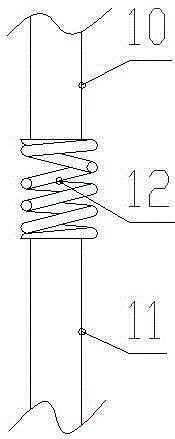

[0032] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the safety device of the resistance type crane of the present invention includes a slide bar 1, a guide bar 2 and a fixed bar 3, and the guide bar 2 and the fixed bar 3 are all welded to the hoisting mechanism 14 (such as being welded to the hoisting mechanism 14), the slide bar 1 is arranged horizontally and the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com