A new cloth pulling device for a cloth stacker

A stacker and a new type of technology, applied in thin material handling, transportation and packaging, winding strips, etc., can solve the problems of reducing work efficiency, time-consuming and laborious, etc., achieving simple structure, reducing safety accidents, and good cloth pulling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

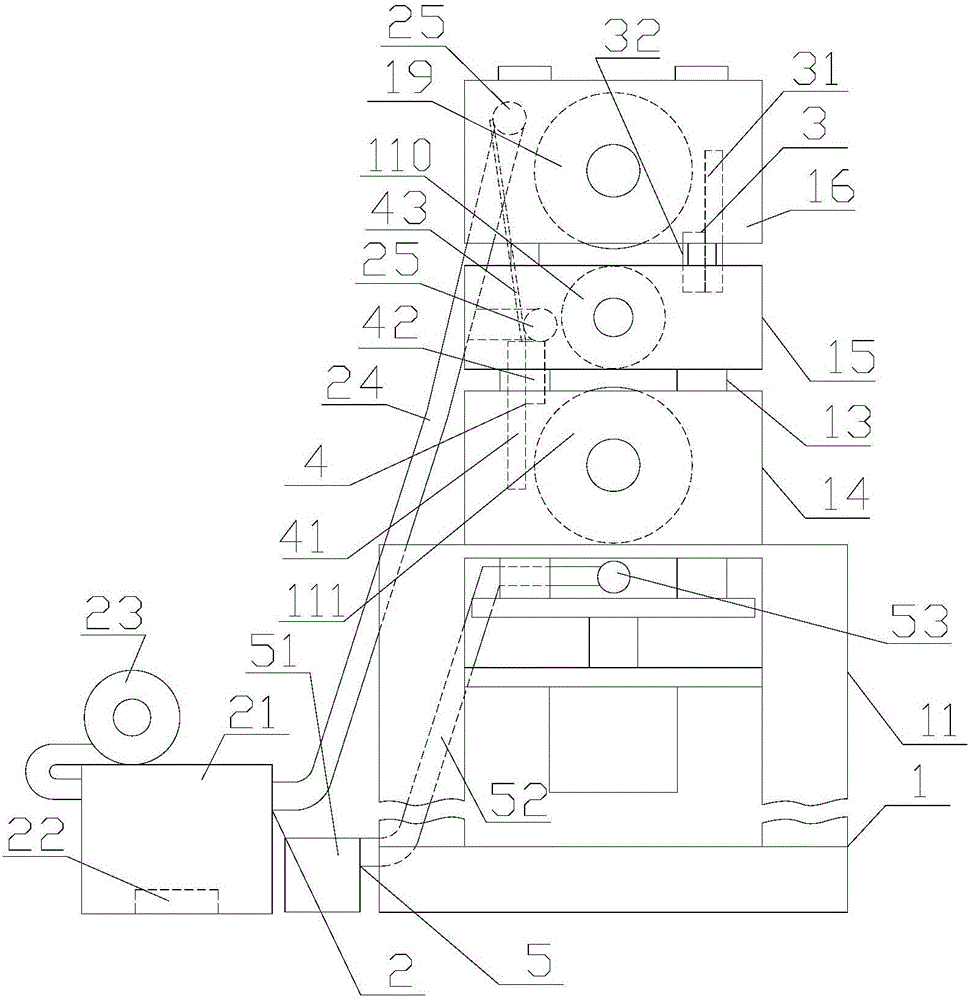

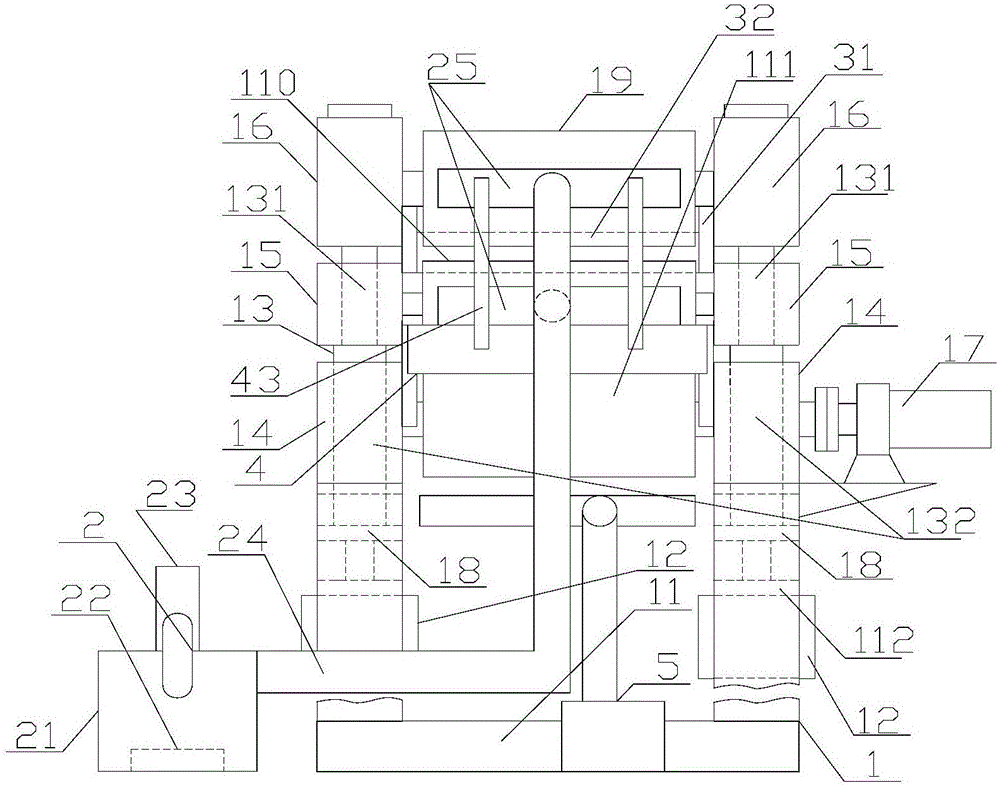

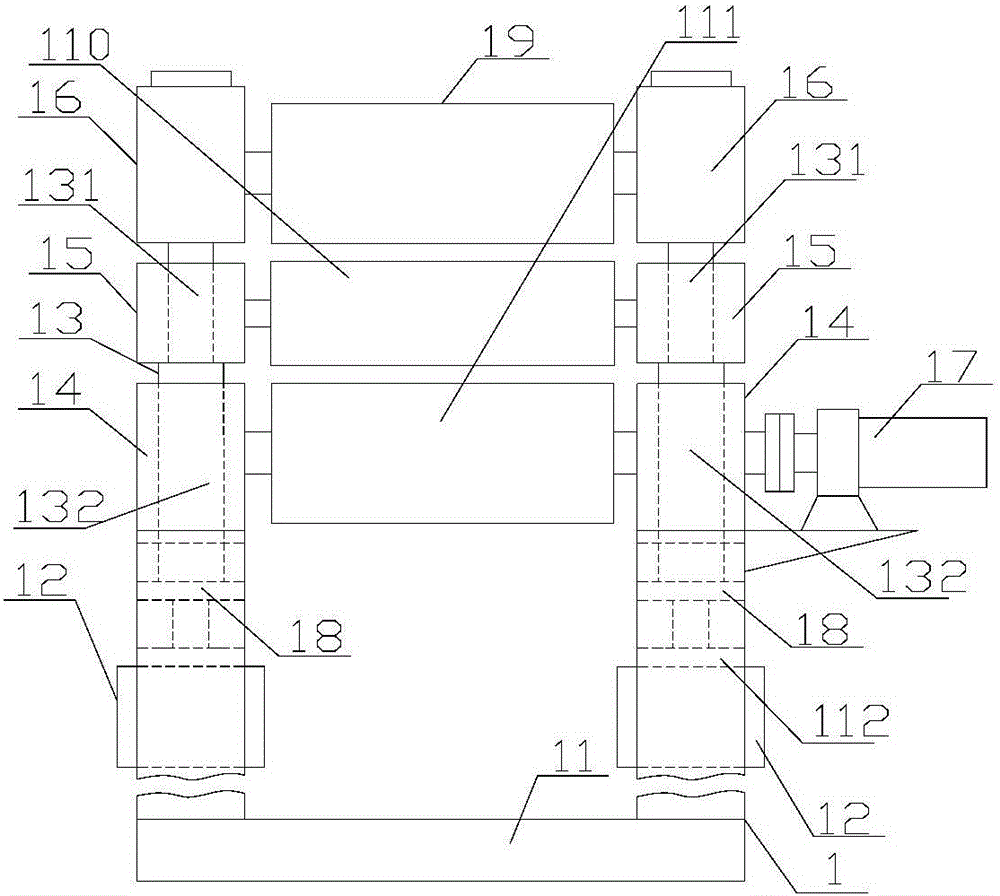

[0023] refer to figure 1 , figure 2 and image 3 , a new cloth pulling device for a cloth stacker according to the present invention, comprising a cloth pulling mechanism 1, a static elimination device 2, a rear protection device 3, a front protection device 4 and a blowing mechanism 5, and the cloth pulling mechanism 1 includes a frame body 11 , two cylinders 12, several push rods 13, two bearings 14, two sliding seats 15, two mounting seats 16, motor 17, push plate 18, upper roller 19, middle roller 110 and lower roller 111, the Both support bodies of the frame body 11 are provided with a cylinder 12 and a bearing 14, and the lower roller 111 is installed on the bearing 14, and the cylinder 12 is arranged under the bearing 14, and the piston rod of the cylinder 12 A push plate 18 is provided on the push plate 18, and a push rod 13 is provided on the push plate 18. The push rod 13 passes through the support 14 and is provided with a slidable sliding seat 15 above the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com