A pe tee pipe processing device

A processing device and tee pipe technology, applied in metal processing and other directions, can solve problems such as low production efficiency, complicated process, and difficult manual operation, and achieve the effects of improving production efficiency, convenient and quick operation, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

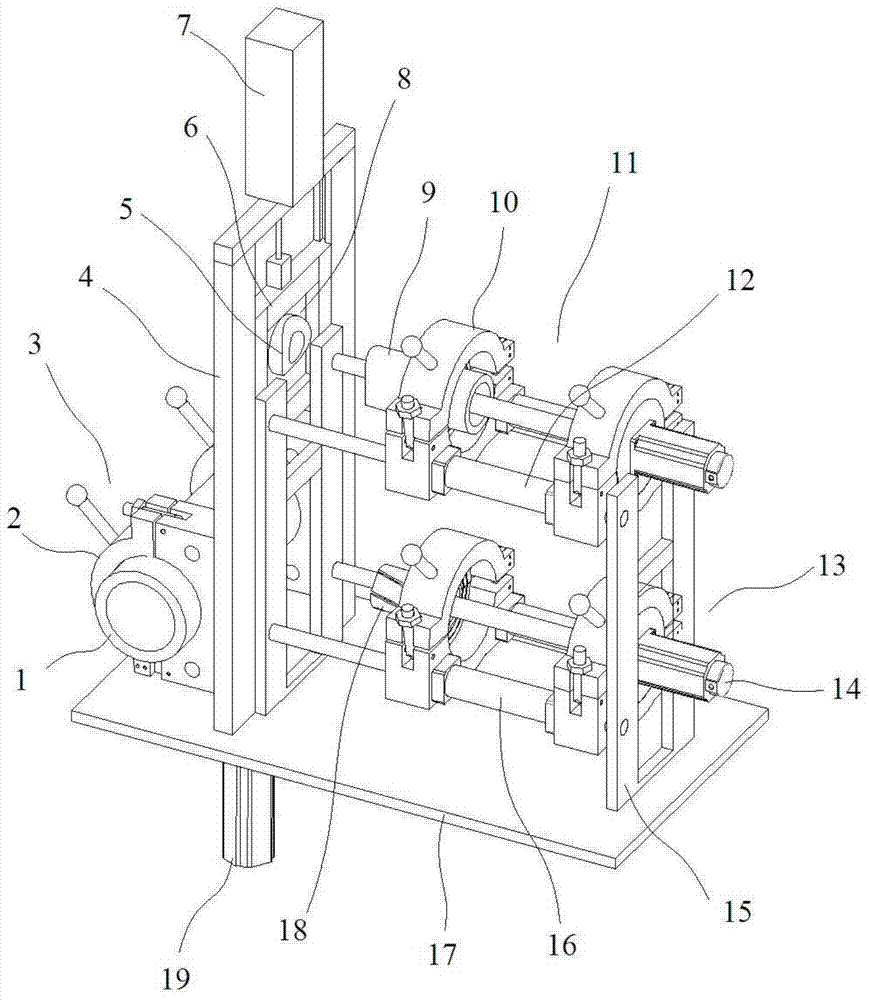

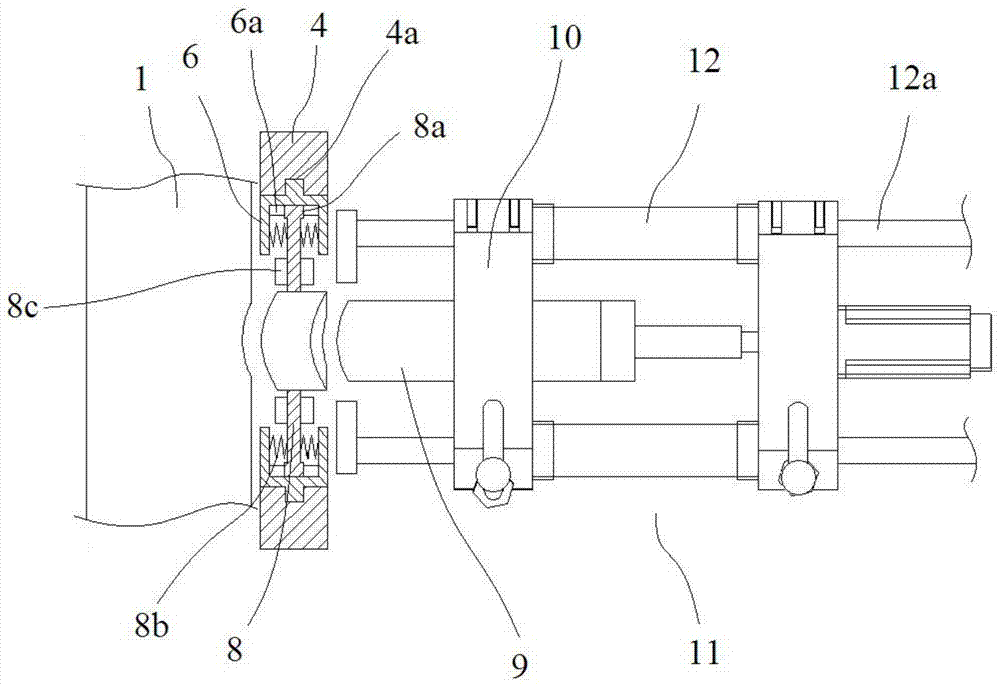

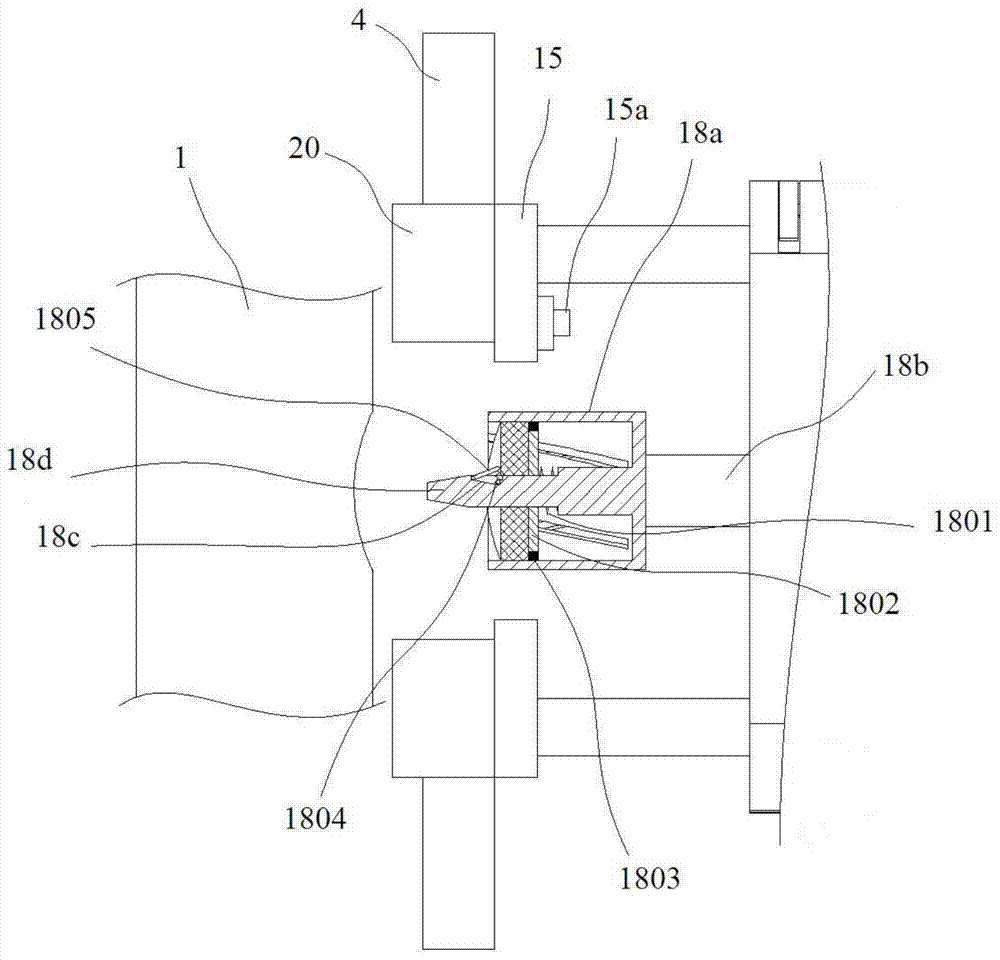

[0019] Such as figure 1 In the shown embodiment, a PE tee pipe processing device includes a stand 17 , a main pipe positioning platform 3 , a branch pipe positioning platform 11 and a punching knife translation platform 13 . Two vertical rails 4 are provided on the platform, and the supervisor positioning platform can slide along the vertical rails. Meanwhile, the supervisor cylinder 19 is arranged under the platform, which can drive the supervisor positioning platform to move along the vertical tracks. The supervisor positioning platform is provided with a supervisor positioning snap ring 2, and the supervisor 1 is horizontally positioned. The stand is provided with a positioning bracket 15, and the positioning bracket is positioned at the side where the competent positioning platform cooperates with the vertical track, so that the vertical t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com