Clamping device for spring type accessory machining

A clamping device and spring-type technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of difficult to guarantee processing quality, unsafe, low efficiency, etc., and achieve the effect of improving efficiency and rapid processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail below by specific embodiments:

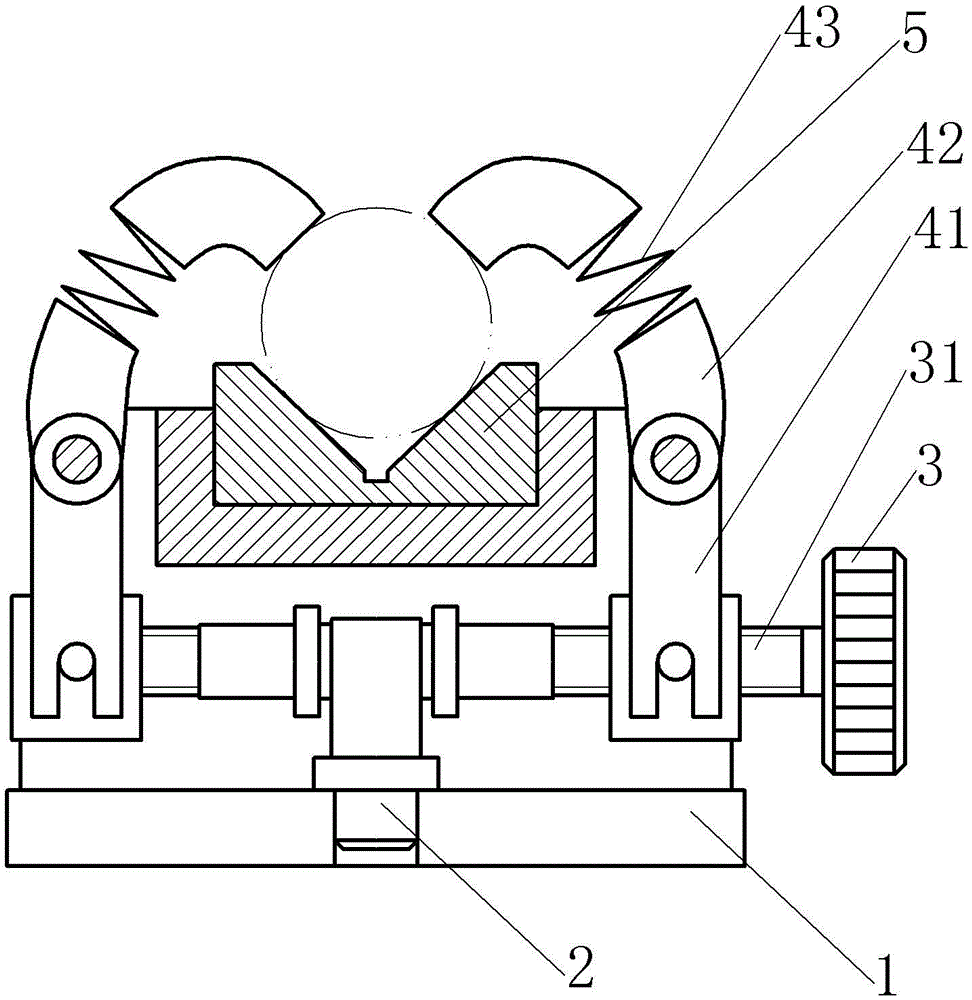

[0015] Reference numerals in the accompanying drawings include: base 1 , hinged support 2 , knob 3 , driving rod 31 , swing arm 41 , connecting portion 42 , spring 43 , and V-shaped block 5 .

[0016] The example is basically as attached figure 1 Shown: A clamping device for spring-type jewelry processing, which includes a base, a hinged support, a knob, a driving rod, a clamping claw and a V-shaped block, wherein the upper part of the base is provided with a strip-shaped groove, and the V-shaped block is connected by bolts In the strip groove, and the angle between the two inclined surfaces of the V-shaped block is 90 degrees, the V-shaped block is made of rubber, and the clamping claws are two distributed on both sides of the V-shaped block, and the two clamping The claws are symmetrically distributed about the V-shaped block, and the clamping claws include a movable part, a spring,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com