High-voltage suspension type MOSFET/IGBT continuous grid driving circuit

A gate drive circuit and drive circuit technology, applied in electrical components, excitation or armature current control, output power conversion devices, etc., can solve problems such as power amplification, limit the application range of power drive circuits, etc. Easy to debug effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the drawings:

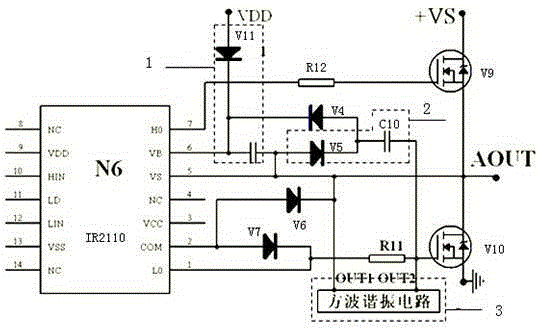

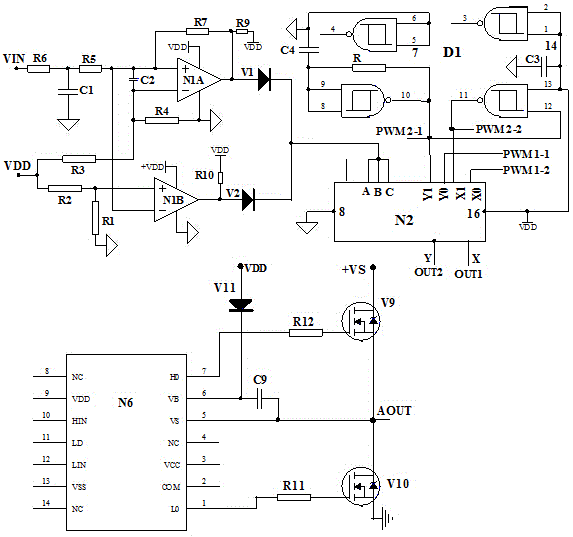

[0015] Such as figure 2 As shown, the high-voltage floating MOSFET / IGBT continuous gate drive circuit of this embodiment includes a square wave resonant circuit 3, a charging circuit 1, an amplitude discriminating circuit 4, and a channel switching circuit 2. The amplitude discriminating circuit 4 is used to discriminate the input signal State, to provide a switch control signal for the channel switching circuit 2. When the input signal is in the linear region, it outputs a low-level signal, and when the input signal is outside the linear region, it outputs a high-level signal; the channel switching circuit 2 is used to identify according to the amplitude The output switch control signal of the circuit 4 switches the input signal channel of the drive circuit. When the amplitude discrimination circuit 4 outputs a low-level signal, it outputs a normal widened square wave signal to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com