Light source assembly and backlight module

A light source component and component technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of large LED spacing, reduced light energy utilization, and high luminous power, and achieve good luminous uniformity, improved uniformity, and high light source The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

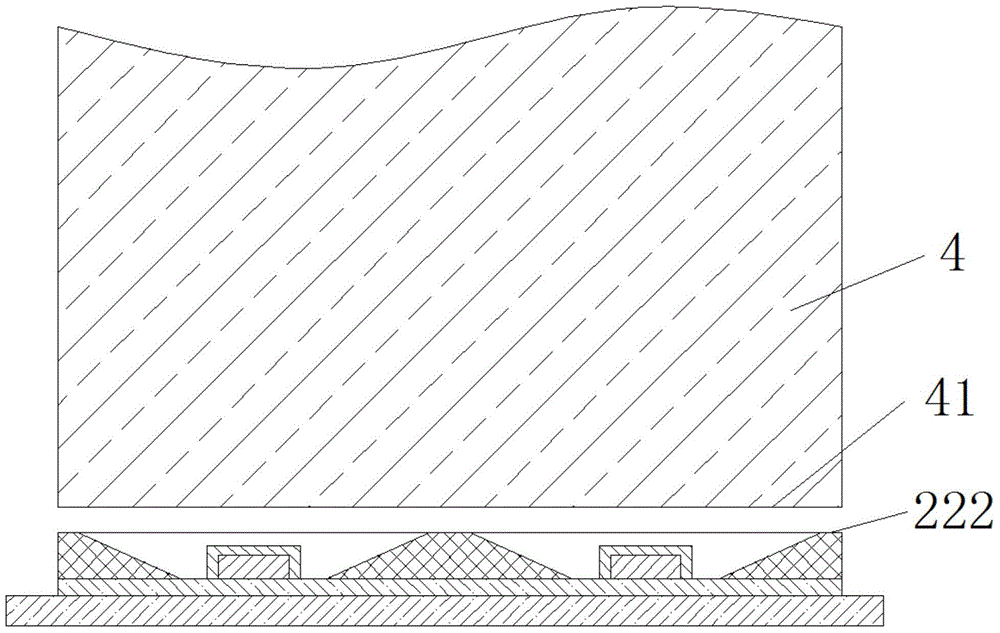

[0024] see figure 1 and figure 2 , the embodiment of the present invention provides a light source assembly, including a circuit board 1 , a reflection assembly 2 and a plurality of light emitting diode chips 3 . The reflection assembly 2 includes a reflection sheet 21 and a reflection bracket 22 , and the reflection sheet 21 is stacked between the circuit board 1 and the reflection bracket 22 . The reflective bracket 22 includes a first surface 221 and a second surface 222 oppositely disposed and a plurality of reflective ring surfaces 223, one end of the plurality of reflective ring surfaces 223 communicates with the first surface 221 and forms a plurality of first Openings 225 , the other ends of the plurality of reflective ring surfaces 223 communicate with the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com