Low-speed wind tunnel double-sawtooth fixing transition tape based on vehicle sticker technology

A transition belt and technology, which is applied in the field of surface boundary layer transition of wind tunnel test models, can solve the problems of small selection range of transition belt height, inability to fit the surface well, and damage to the surface roughness of the model. Achieve the effect of improving test quality and efficiency, with a wide range of sizes and optional thicknesses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

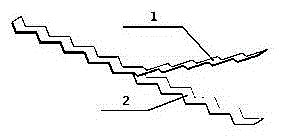

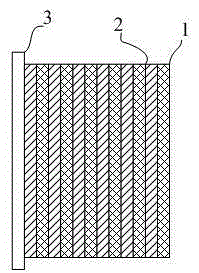

[0031] Such as figure 1 , figure 2 As shown, considering that in the actual wind tunnel test, the overall thickness of the transition zone needs to be between 0.1mm and 0.3mm, the thickness of each layer of PVC film in the transition zone is designed to be 0.01mm, and the adhesive PVC film is designed as Colored PVC film, the anti-adhesive PVC film is designed as a transparent PVC film to show the difference.

[0032]When in use, when the tested model needs to paste a certain thickness of the transition belt, by calculating the number of layers of PVC film, the thickness of the tear can be precisely controlled, and it can be pressed and pasted on the tested model. When it is necessary to paste the transition belt with an even thickness, such as 0.12mm and 0.24mm, then tear off the protective layer from the bottom of the entire transition belt, and then press and stick the entire transition belt on the model under test. Then count the even-numbered layers from the bottom lay...

Embodiment approach 2

[0035] On the basis of Embodiment 1, the transition zone of the present invention is further improved, because the actual required thickness of the transition zone is between 0.1 mm and 0.3 mm, then the top layer and the top layer of the entire transition zone can be designed as 0.09mm, and the other layers between the top layer and the bottom layer are still designed to be 0.01mm, so that the waste of layers between 0.01mm and 0.09mm can be reduced, making the transition zone design more reasonable.

[0036] The specific usage steps are the same as the first embodiment. According to the thickness of the transition belt to be pasted, consider whether to tear it from the bottom layer or from the top layer, and then subtract the 0.09mm of the top layer or bottom layer from the actual thickness to get the required number of other layers. , to achieve high-precision thickness control.

Embodiment approach 3

[0038] Of course, without considering the processing cost, the transition belt can be designed as one layer, and several transition belts with different thicknesses can be designed according to the thickness of the paste. When a transition belt with a certain thickness is required, the transition belt can be directly The protective layer is torn off, and the transition belt can be pasted on the model.

[0039] The advantage of this method is that there is no need to calculate the number of layers, just paste it directly according to the thickness, but the disadvantage is that the design requires several molds to process PVC films of different thicknesses. loaded down with trivial details, and production cost obviously improves.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com