Load detection device

A detection device and load technology, applied in the direction of measurement device, force measurement, tension measurement, etc., can solve the problems of reduced output signal sensitivity, amplitude limitation of compressive strain, and difficulty in detecting strain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, a load detection device according to an embodiment of the present invention will be described with reference to the drawings.

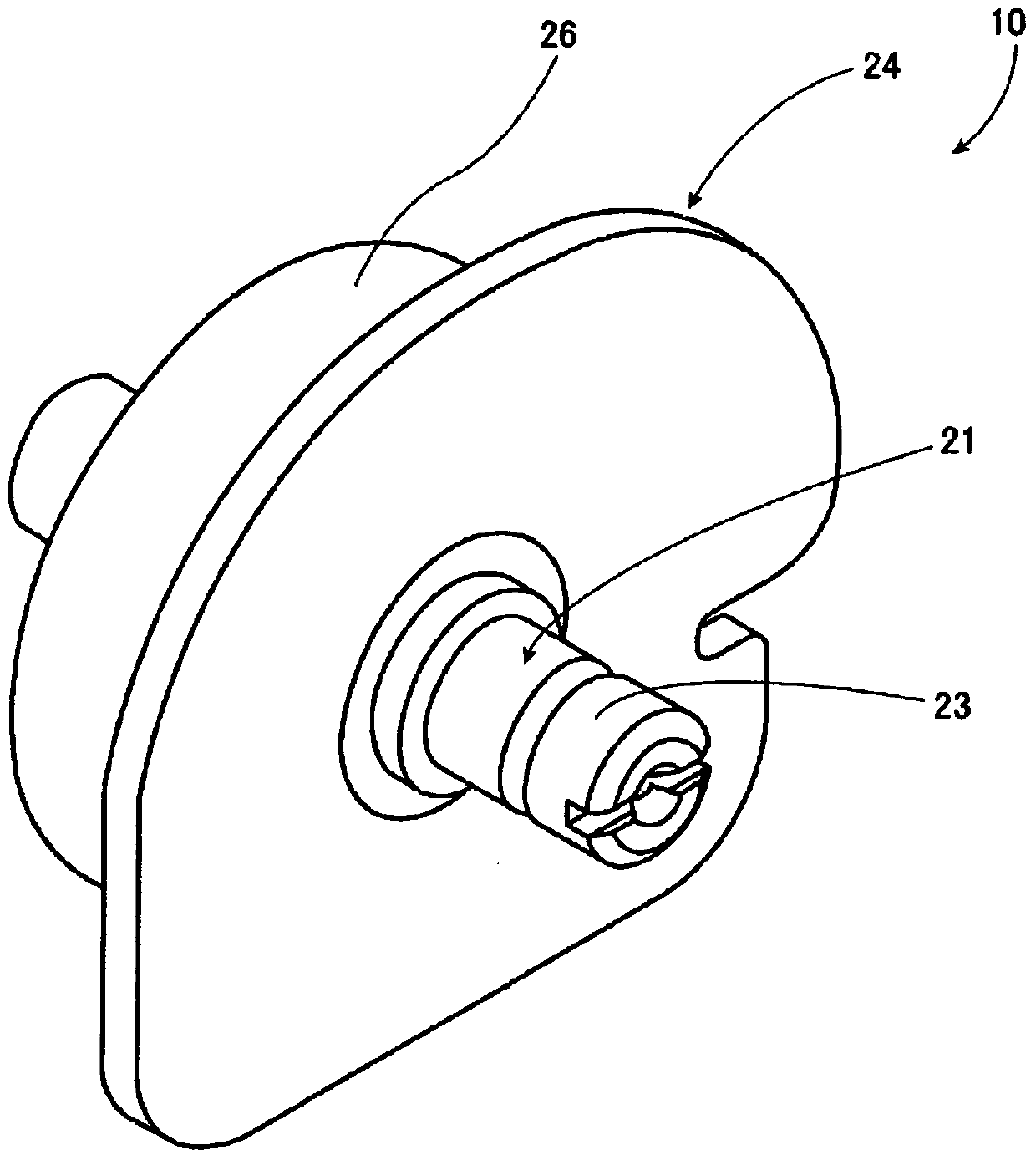

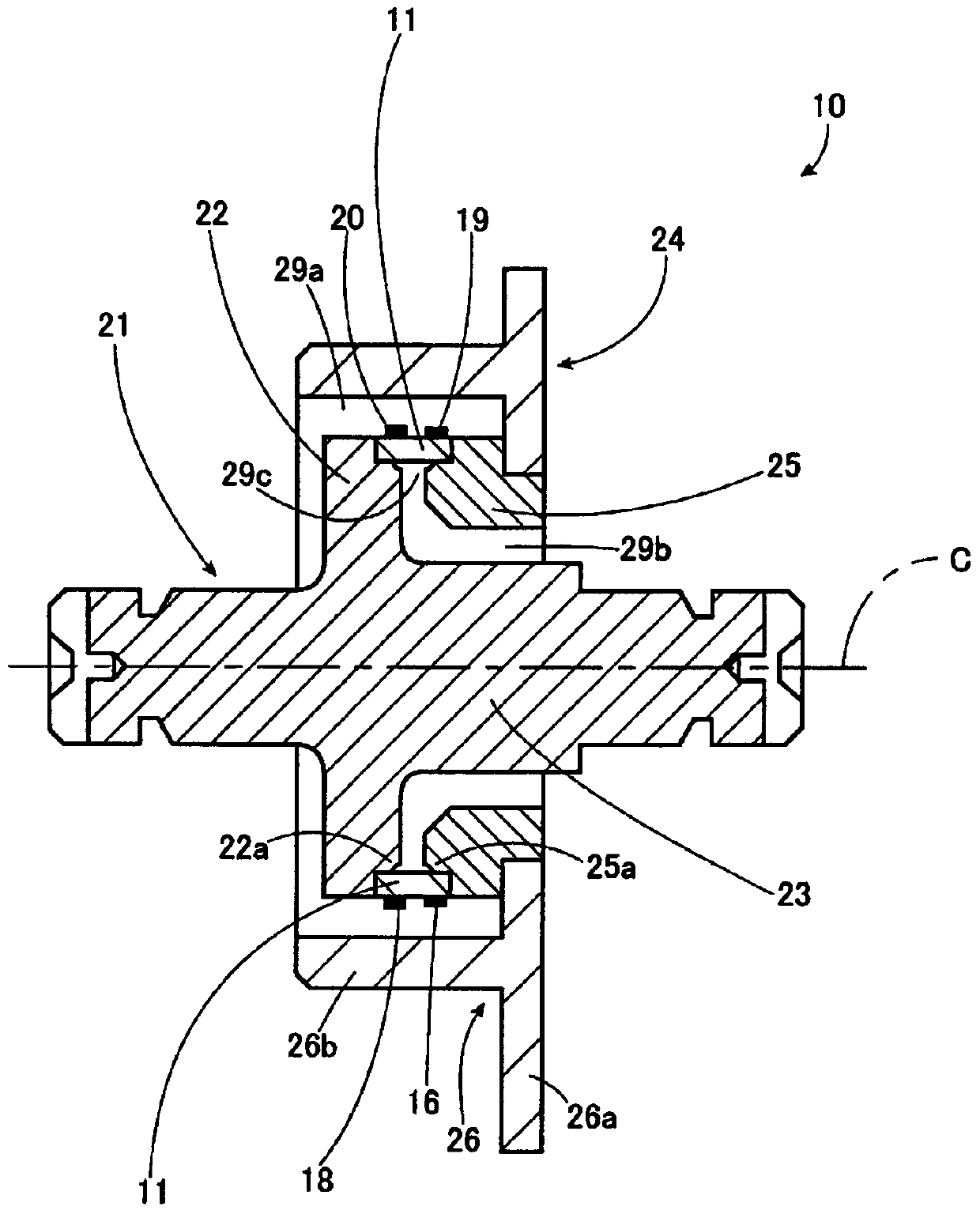

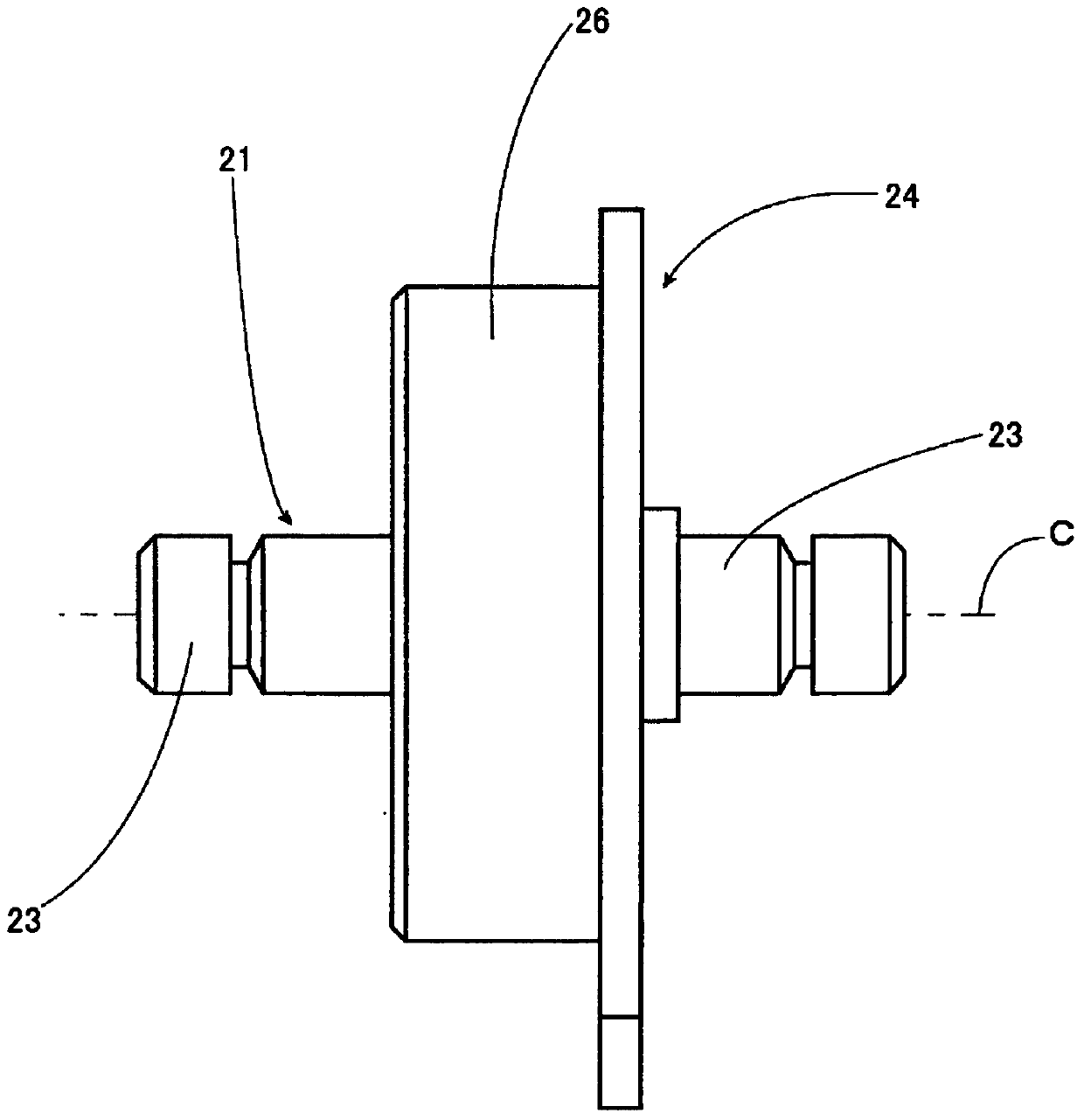

[0030] figure 1 is a perspective view showing a load detection device 10 as an example of the present invention, figure 2 yes figure 1 A longitudinal sectional view of the load detection device 10 shown, image 3 yes figure 1 A side view of the load detection device 10 is shown, Figure 4 It is a developed view of the strain body used in the load detection device 10 .

[0031] like Figure 1 to Figure 4 As shown, the load detecting device 10 includes a straining body 11 having a hollow shape, a fixing member (first part) 21 having a generally shaft-shaped configuration, and a generally ring-shaped—that is, an annular structure arranged coaxially with each other. Shape - the moving part (second part) 24. exist figure 2 and 4 , for example, a metallic hollow cylindrical strain body 11 made of ferritic stainless steel an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com