Production process for liquid accumulator

A production process and liquid storage technology, which is applied in the production process of liquid storage, can solve the problems that the refrigerant cannot be completely vaporized, affects the service life of the liquid storage, and the joint of the liquid storage is weak, etc., so as to achieve good sealing , flexible use and high liquid discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

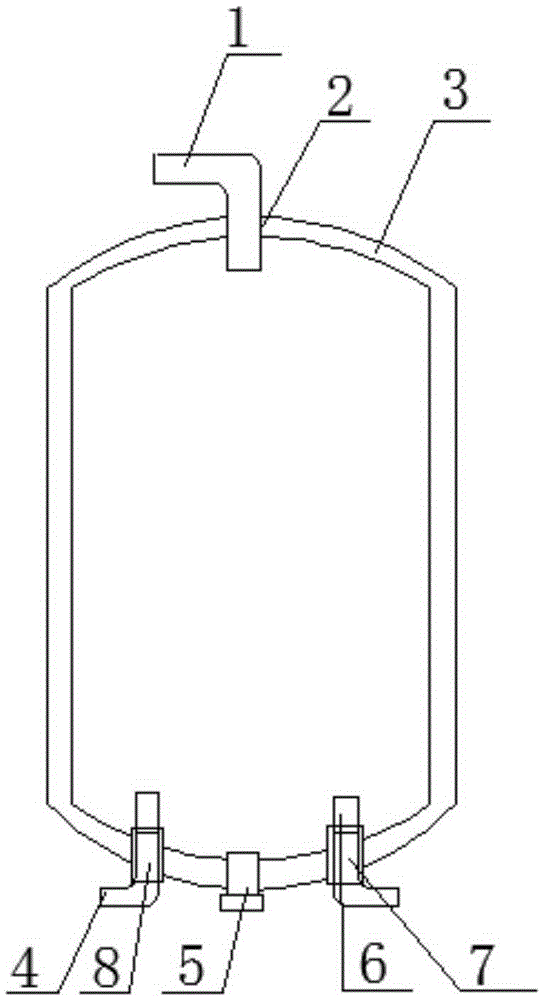

[0023] Embodiment 1: a kind of production technology of liquid reservoir, it is characterized in that: comprise the following steps:

[0024] a. Spinning forming: use the spinning process to process the blank into the reservoir body 3;

[0025] b. Drilling density: Drill a through hole at the joint at the bottom of the reservoir body 3, and weld a plug 5 at the through hole;

[0026] c. Processing of the liquid inlet hole 2 and the liquid outlet hole 7: drill a liquid inlet hole 2 on the upper surface of the liquid reservoir body 3, and drill two liquid outlet holes 7 at positions symmetrical to the center line on the lower surface of the blank;

[0027] d. Welded pipe: weld the liquid inlet pipe 1 at the liquid inlet hole 2, and weld the liquid outlet device at the liquid outlet hole 7.

[0028] The production process of the above-mentioned liquid reservoir, wherein the spinning process includes the following steps:

[0029] (1) Spinning: After the billet is checked for no ...

Embodiment 2

[0032] Embodiment 2: a kind of production technology of liquid reservoir, it is characterized in that: comprise the following steps:

[0033] a. Spinning forming: use the spinning process to process the blank into the reservoir body 3;

[0034] b. Drilling density: Drill a through hole at the joint at the bottom of the reservoir body 3, and weld a plug 5 at the through hole;

[0035] c. Processing of the liquid inlet hole 2 and the liquid outlet hole 7: drill a liquid inlet hole 2 on the upper surface of the liquid reservoir body 3, and drill two liquid outlet holes 7 at positions symmetrical to the center line on the lower surface of the blank;

[0036] d. Welded pipe: weld the liquid inlet pipe 1 at the liquid inlet hole 2, and weld the liquid outlet device at the liquid outlet hole 7.

[0037] The production process of the above-mentioned liquid reservoir, wherein the liquid outlet device includes a straight pipe 6 and an elbow 4 , and the straight pipe 6 and the elbow 4 a...

Embodiment 3

[0039] Embodiment 3: a kind of production technology of liquid reservoir, it is characterized in that: comprise the following steps:

[0040] a. Spinning forming: use the spinning process to process the blank into the reservoir body 3;

[0041] b. Drilling density: Drill a through hole at the joint at the bottom of the reservoir body 3, and weld a plug 5 at the through hole;

[0042] c. Processing of the liquid inlet hole 2 and the liquid outlet hole 7: drill a liquid inlet hole 2 on the upper surface of the liquid reservoir body 3, and drill two liquid outlet holes 7 at positions symmetrical to the center line on the lower surface of the blank;

[0043] d. Welded pipe: weld the liquid inlet pipe 1 at the liquid inlet hole 2, and weld the liquid outlet device at the liquid outlet hole 7.

[0044] The production process of the above-mentioned liquid reservoir, wherein the spinning process includes the following steps:

[0045] (1) Spinning: After the billet is checked for no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com