Combined metal filling box with slurry blocking pieces

A metal filling and combined technology, applied in the field of filling materials and combined metal filling boxes, can solve the problems of inability to effectively guarantee the quality of concrete pouring, poor integrity of filling materials, and high buoyancy of filling materials, and achieve good economy and applicability. , The development of construction technology promotes, the effect of large span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is realized in the following manner:

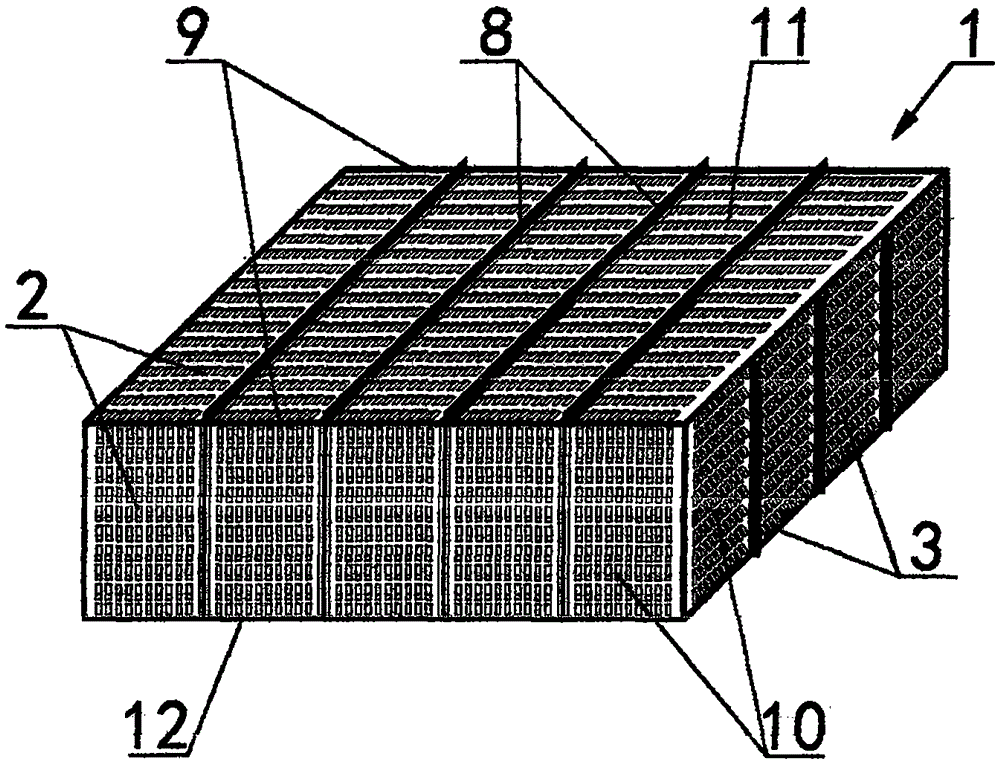

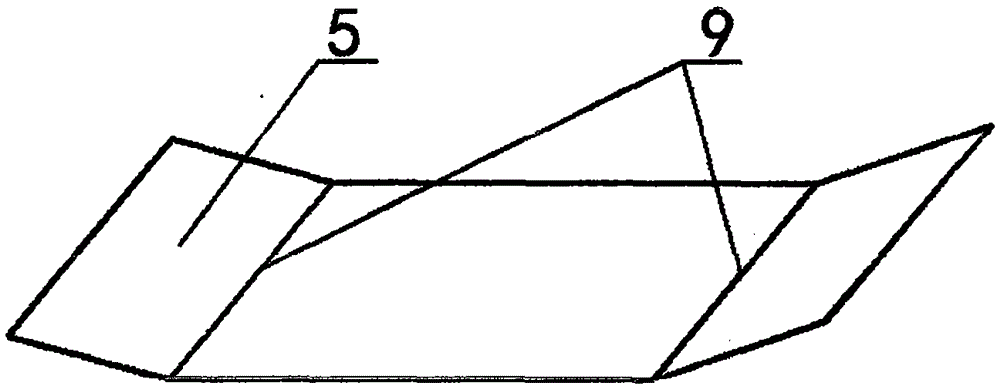

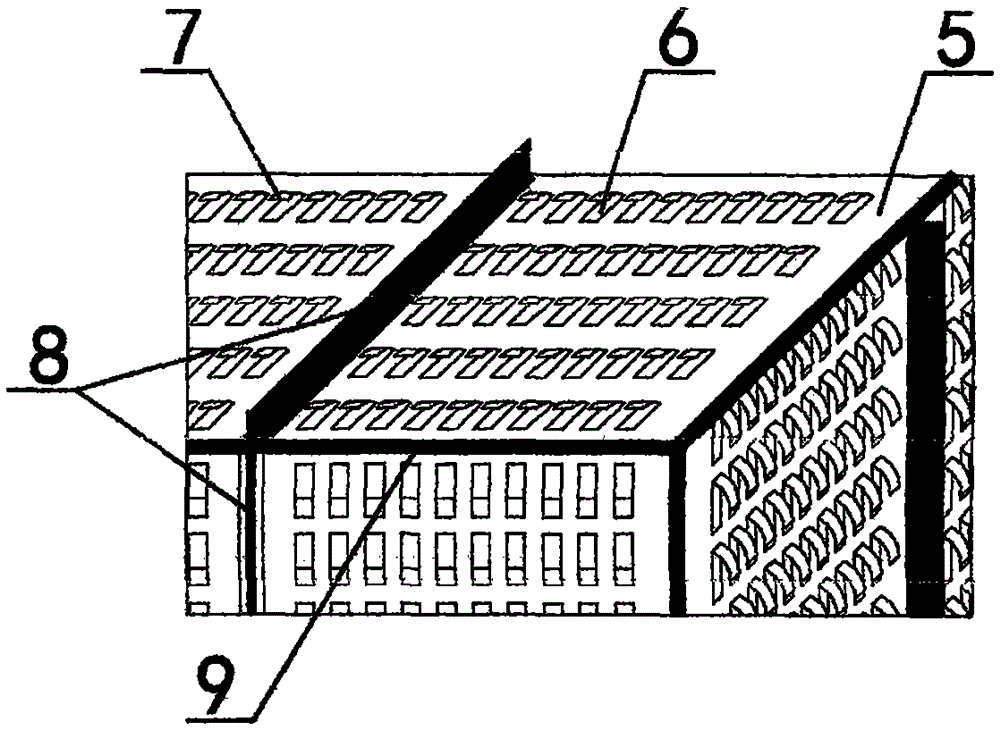

[0038] exist Figure 1-Figure 4 In the shown embodiment, a combined metal filling box with blocking paddles, the filling box (1) includes an upper assembly (2), a lower assembly (3), and a bracket (4), in a strip shape with a thickness of less than 1 mm Dense meshes (6) are formed on the metal sheet (5) by die-cutting, the short dimension of a single mesh (6) is ≥4mm and ≤12mm, and the long dimension of a single mesh (6) is ≥5mm and ≤15mm , the metal sheet that is punched out from the mesh (6) forms an outwardly warping slurry-resistance sheet (7), and one end of the slurry-resistance sheet (7) is still connected with the metal sheet (5) base material, and each sheet of metal The thin plate (5) has two bending lines (9), and the two ends of the metal thin plate (5) are bent 90° in the same direction along the bending lines (9) to form an upper assembly with a U-shaped structure with three surfaces ( 2) and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com