Prestressed pipe pile upright

A technology for prestressed pipe piles and pipe piles, which is applied to sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of mud pollution, high economic cost, and complicated processing, so as to improve the overall rigidity, speed up the construction progress, and improve the construction efficiency. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

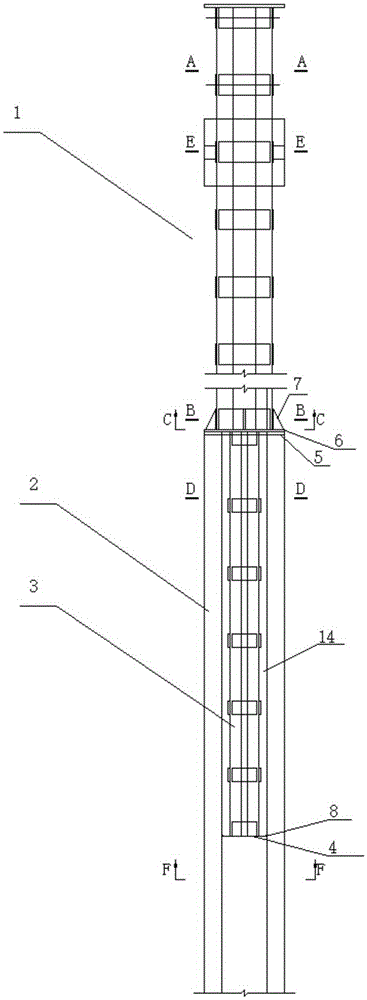

[0047] Embodiment: A prestressed pipe pile column, including a steel lattice column 1, a pipe pile 2 and a pipe pile insert 3, the pipe pile insert 3 is coaxially fixedly connected to the lower end of the steel lattice column 1, and the pipe pile insert 3 It is fixedly inserted into the ring-shaped cylindrical pipe pile 2, the lower end of the steel lattice column 1 is fixedly connected with the upper end of the pipe pile core 3, the upper end of the pipe pile core 3 is connected with the pipe pile end plate 5 on the top of the pipe pile 2, and the pipe pile inserts The lower end of the core 3 is fixedly equipped with a supporting plate, and the supporting plate and the inner space of the pipe pile 2 above the supporting plate form a pouring space, and the expansive concrete 14 is poured in the pouring space.

[0048] in:

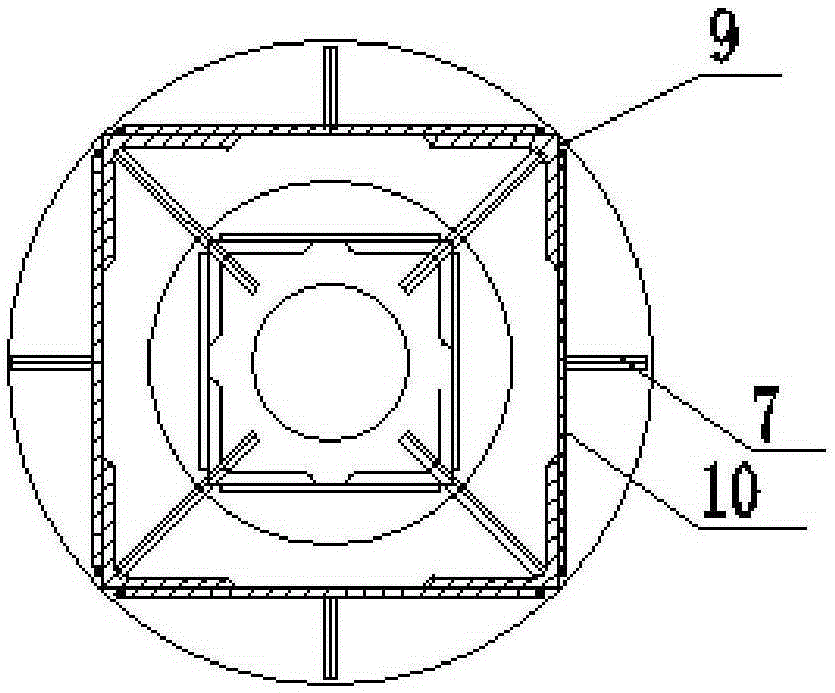

[0049] The steel lattice column 1 generally includes four L-shaped angle steels and several groups of panels 10, the four L-shaped angle steels enclose a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com