Pressing system restraining blast furnace hearth plate from warping upwards and application thereof

A blast furnace and bottom plate technology, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as potential safety hazards and economic losses, achieve stable blast furnace production, eliminate the influence of furnace bottom sealing plate warping, and prevent leakage The effect of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

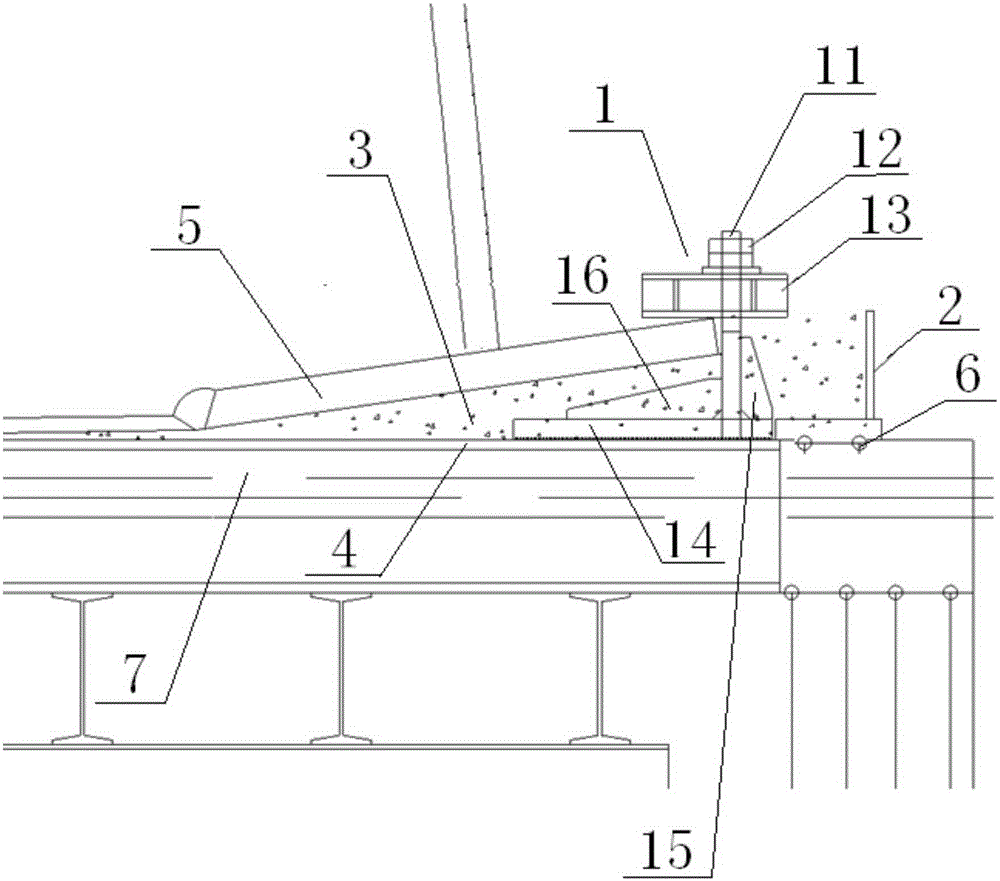

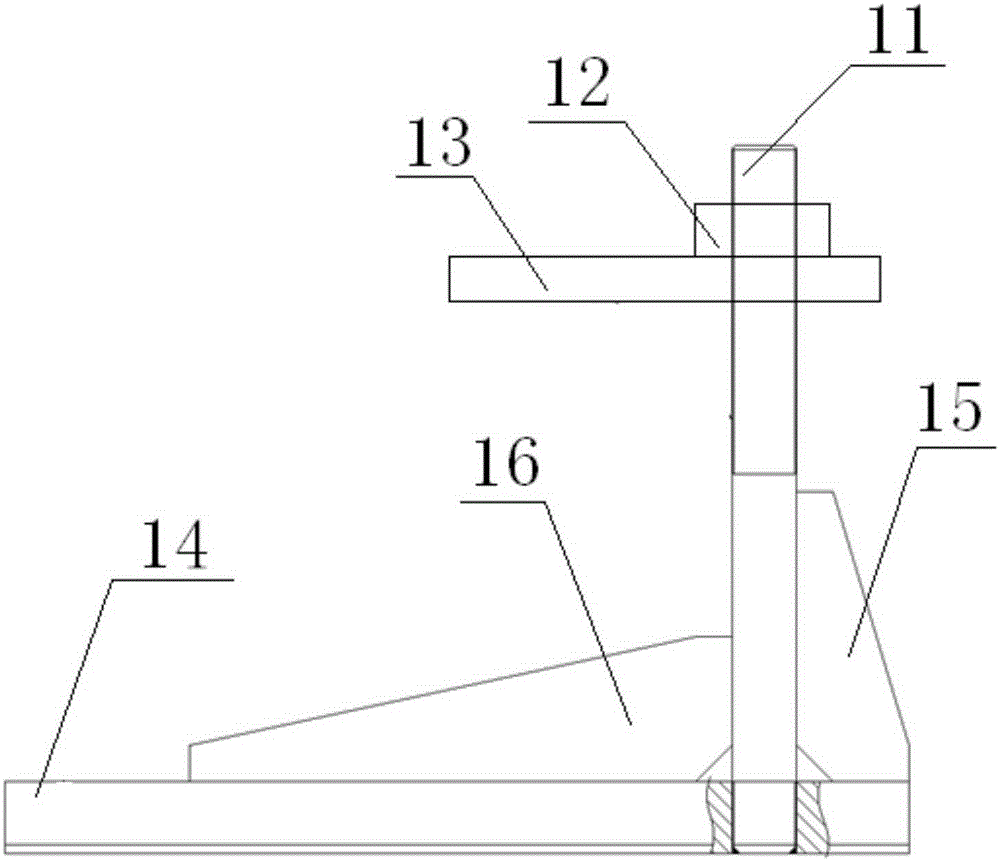

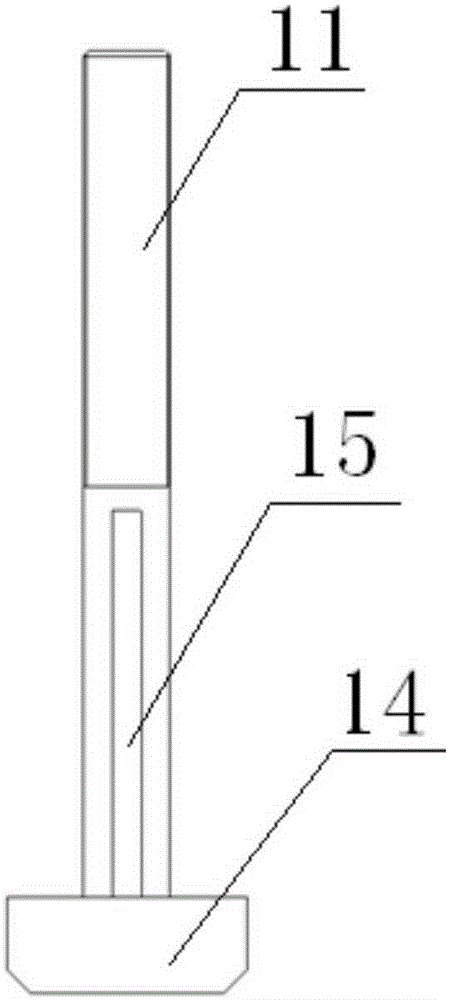

[0046] A kind of compacting system of this embodiment that suppresses the upturning of the bottom plate of the blast furnace, such as figure 1 As shown, it includes a pressing device 1, an annular retaining ring 2 and a pouring material 3; as figure 2 and 3 As shown, the main body section of the pressing device 1 is in the shape of a left-right asymmetric "earth", including a pressure plate 13 and a bottom plate 14 parallel to each other, and a bolt 11 fixedly connected to the bottom plate 14 after passing through the pressure plate 13; and through a nut 12 Adjust the height of the pressing plate 13; the bottom plate 14 of the pressing device 1 is inserted into the bottom of the upturned furnace bottom sealing plate 5, and is pressed on the top of the upturned furnace bottom sealing plate 5 through the pressing plate 13, and the rotating nut 12 compacts the upturned furnace bottom The sealing plate 5; the castable 3 is filled in the gap formed by the upturned furnace bottom ...

Embodiment 2

[0057] A compacting system of this embodiment that suppresses the upturning of the bottom plate of a blast furnace has the same basic structure as that of Embodiment 1, and the improvement is that the pressing plate 13, the bottom plate 14, the rib A15 and the rib B16 in the compacting device 1 are all Made from steel scraps. The self-flowing castable with high thermal conductivity is mixed with the following materials in parts by weight: SiC, 85 parts; aqueous binder, 25 parts; corundum, 15 parts; water reducer and dispersant, 1 part in total. After testing, the castable meets the parameter requirements, and the castable also has the characteristics of ①good fluidity, which meets the construction conditions; ②low line change rate.

Embodiment 3

[0059] A compacting system of this embodiment that suppresses the upturning of the blast furnace bottom plate has the same basic structure as that of Embodiment 1, except that the high thermal conductivity self-flowing castable is mixed with the following materials in parts by weight: SiC, 90 parts; containing water Adhesive, 30 parts; corundum, 19 parts; water reducer and dispersant, 1 part in total. After testing, the castable also meets the parameter requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com