Preparation method for polyimide thin film

A technology of polyimide film and polyamic acid, which is applied in the field of preparation of partially cross-linked polyimide film, can solve the problems of low thermal conductivity of graphite film and the need to improve the thermal conductivity of graphite film, and achieve simple process, The effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

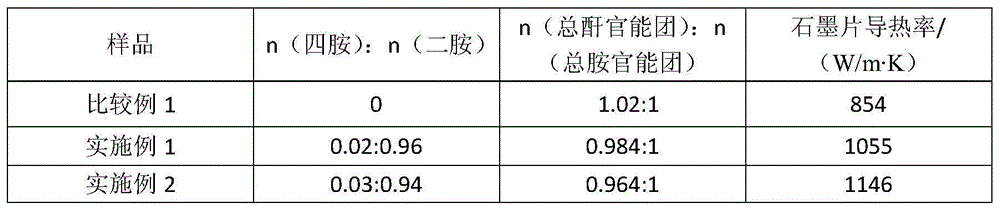

Embodiment 1

[0031](1) Under nitrogen protection at 20-25°C, weigh 6g of 4,4'-diaminodiphenyl ether (ODA) and 0.1337g of 3,3'-diaminobenzidine (TAB) into 50ml of N-methylpyrrolidone (NMP ), dissolved under mechanical stirring. After complete dissolution, lower the reaction system below 5°C, add 3g of pyromellitic anhydride (PMDA) while stirring, and rinse the inner wall of the device with 10ml of NMP. After reacting for 1.5 h, add 3 g of PMDA while stirring, and rinse the inner wall of the device with 10 ml of NMP. After reacting for 1.5 h, add 0.5 g PMDA while stirring, and rinse the inner wall of the device with 10 ml NMP. At this time, the viscosity of the system began to rise. After 2 hours of reaction, 0.2 g of PMDA was added while stirring. After 2 hours, the reaction system formed a viscous polyamic acid solution. At this time, the total amount of the added dianhydride PMDA was 6.7 g. The molar ratio of the amount of tetraamine TAB to the amount of diamine ODA in this system is 0...

Embodiment 2

[0034] (1) Under nitrogen protection at 20-25°C, weigh 6g of 4,4'-diaminodiphenyl ether (ODA) and 0.2049g of 3,3'-diaminobenzidine (TAB) into 50ml of N-methylpyrrolidone (NMP ), dissolved under mechanical stirring. After complete dissolution, lower the reaction system below 5°C, add 3g of pyromellitic anhydride (PMDA) while stirring, and rinse the inner wall of the device with 10ml of NMP. After reacting for 1.5 h, add 3 g of PMDA while stirring, and rinse the inner wall of the device with 10 ml of NMP. After reacting for 1.5 h, add 0.5 g PMDA while stirring, and rinse the inner wall of the device with 10 ml NMP. At this time, the viscosity of the system began to rise, and after 2 hours of reaction, 0.2 g of PMDA was added. After 2 hours, the reaction system formed a viscous polyamic acid solution. At this time, the total amount of the added dianhydride PMDA was 6.7 g. The molar ratio of the amount of tetraamine TAB to the amount of diamine ODA in this system is 0.03:0.94, ...

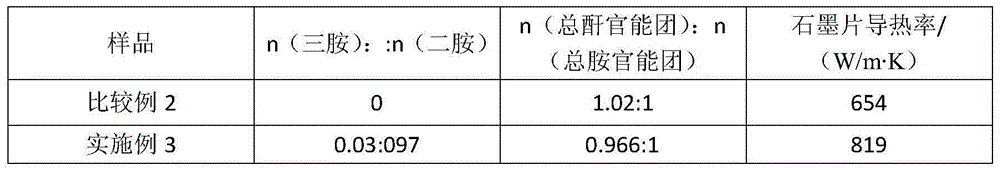

Embodiment 3

[0043] (1) Under nitrogen protection at 20-25°C, weigh 1.1573g of 4,4'-diaminodiphenyl ether (ODA), 2.50g of p-phenylenediamine (PDA) and 0.11g of 1,3,5-triaminobenzene Dissolve in 50ml N,N-dimethylacetamide (DMAc) under mechanical stirring. After complete dissolution, lower the reaction system below 5°C, add 4g of 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA) while stirring, and rinse the inner wall of the device with 10ml of DMAc. After reacting for 1.5 h, add 2 g of BPDA while stirring, and rinse the inner wall of the device with 10 ml of DMAc. After 1.5 h of reaction, 2.00 g of BPDA was added, and the inner wall of the device was washed with 10 ml of DMAc. After reacting for 2 hours, add 0.6g BPDA, and rinse the inner wall of the device with 10ml DMAc. After 2h, the reaction system formed a viscous polyamic acid solution. At this time, the total amount of dianhydride BPDA added was 8.6 g. The molar ratio of the amount of 1,3,5-triaminobenzene to the amount of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com