Functionalized nano-grade porous polymer material multicomponent reaction preparation method

A polymer material and multi-component reaction technology, applied in the fields of physical chemistry and material chemistry, can solve problems such as complex synthesis process, high cost, and difficult functionalization, and achieve uniform pore size distribution, high-efficiency preparation, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

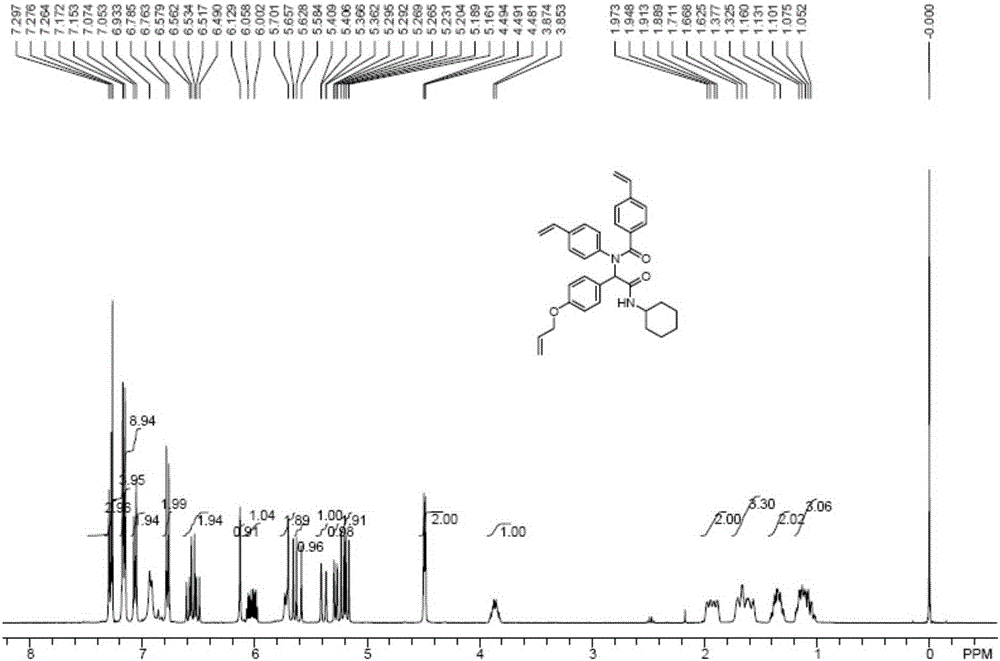

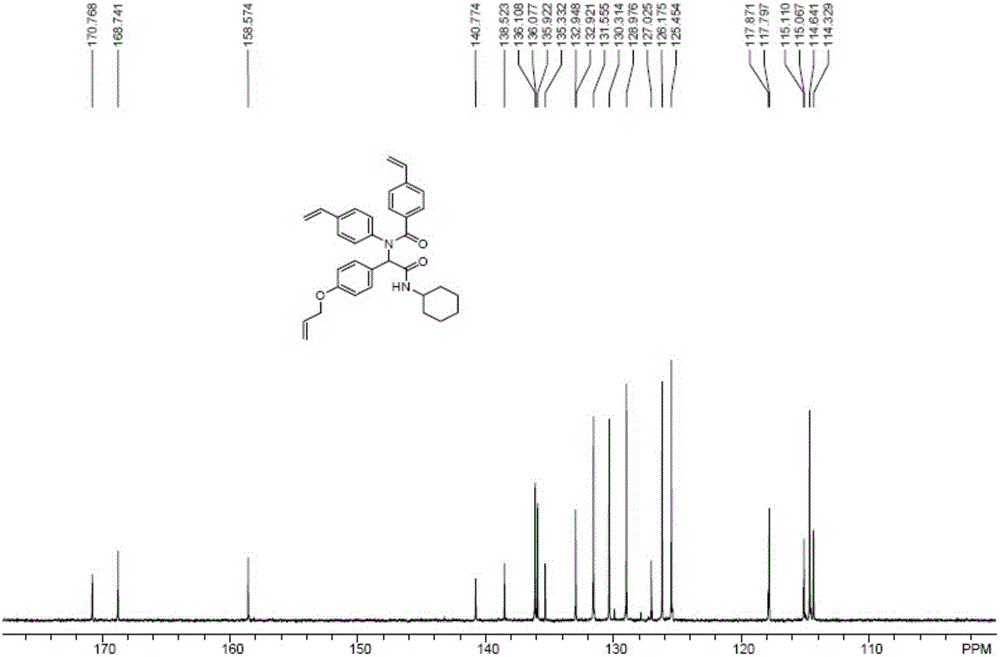

[0016] The invention provides a multi-component reaction preparation method for a functionalized nanoporous polymer material, which includes the following steps. a. Using multi-component synthesis technology to prepare aldehyde reactants containing double bonds: in a 100mL round bottom flask, add stirring magnets, 10mmol of p-hydroxybenzaldehyde, 50mL of N,N-dimethylformamide, allyl Bromine 15mmol and K 2 CO 3 20mmol, after 10 hours at room temperature, the reaction was detected by thin-layer chromatography TLC, and 20mL of water and 200mL of ethyl acetate were added to the reaction mixture, and the organic phase was taken after layering, and the aqueous phase was extracted with ethyl acetate. Washed with saturated NaCl aqueous solution, anhydrous NaCl 2 SO 4 Dry, concentrate under reduced pressure, and separate by column chromatography to obtain the product 4-allyloxybenzaldehyde. The product obtained in step a was 8.5 mmol, and the yield was 85%. The reaction synthesis ...

Embodiment 1

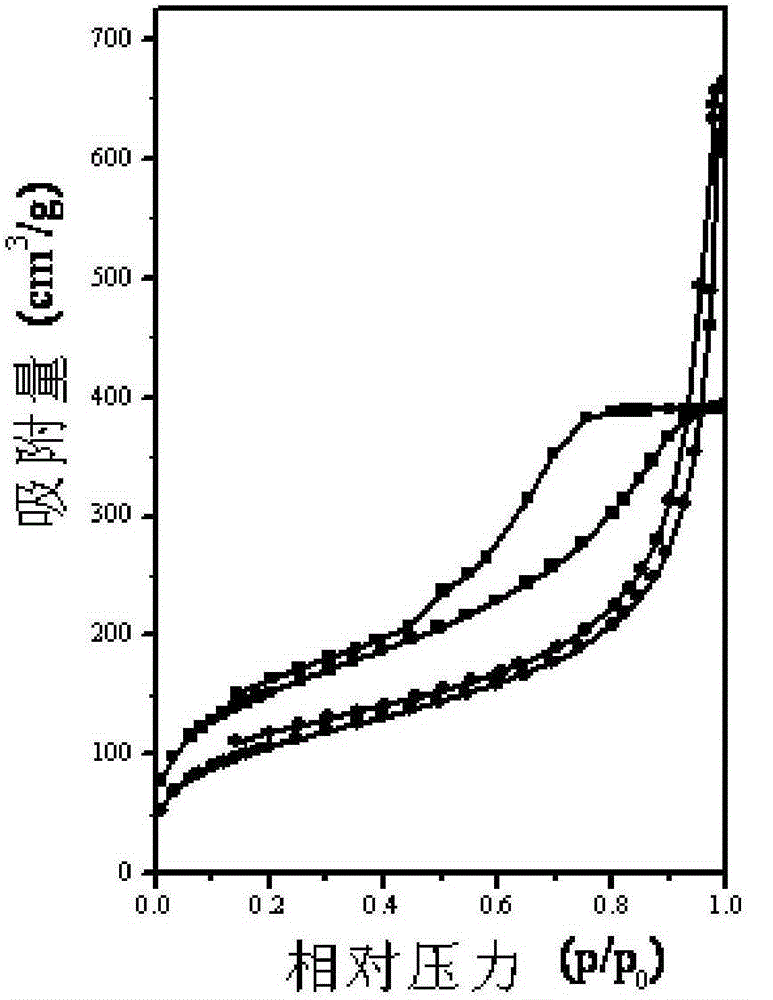

[0025] Take 0.02 g of azobisisobutyronitrile, 2.0 g of divinylbenzene, and 1.5 g of functional monomers, then add 15 g of tetrahydrofuran solvent, stir at room temperature for 3 hours, put in a kettle, and heat-treat with solvent at 100 ° C for 24 hours. The pressure in the reactor is about 2MPa, open the cover, and evaporate the residual solvent at room temperature to obtain a functionalized nanoporous polymer material. The specific surface area of the material is about 400m 2 / g, the pore size is 4nm.

Embodiment 2

[0027] Take 0.1 g of azobisisobutyronitrile, 2.0 g of divinylbenzene, and 2.0 g of functional monomers, then add 20 g of ethyl acetate solvent, stir at room temperature for 3 hours, put it in a kettle, and heat it at 60°C for 48 hours. Inflate with nitrogen, keep the pressure at about 5.0MPa, open the cover, evaporate at room temperature to remove the residual solvent, and then obtain the functionalized nanoporous polymer material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com