Metal organic framework material based on lead nitrate and application thereof

A metal-organic framework and lead nitrate technology, which is applied in the direction of lead organic compounds, organic chemistry, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of scarcity, achieve catalytic silicocyanation reaction, and simple preparation method , Satisfactory catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 A metal-organic framework based on lead nitrate [Pb 2 (BPTC)(H 2 O) 2 ]·2H 2 o

[0028] resolve resolution:

[0029] 1) 15mgPb(NO 3 ) 2 , 5mgH 4 BPTC, 1.5mLDMA, added to the container in turn, ultrasonic vibration to Pb(NO 3 ) 2 and H 4 BPTC is uniformly dispersed in DMA.

[0030] 2) After sealing the container, put it into an oven at 85° C. for 72 hours to react to obtain white cubic crystals.

[0031] 3) The crystals were washed three to five times with DMA and filtered to obtain colorless and transparent cubic crystals with a crystal yield of 72%.

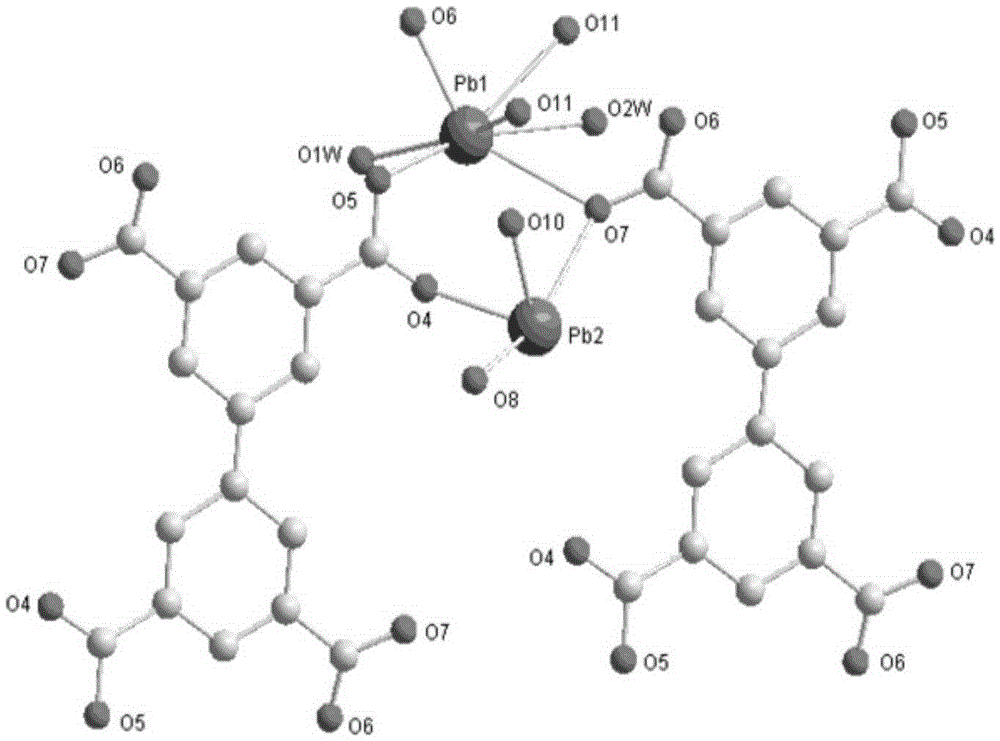

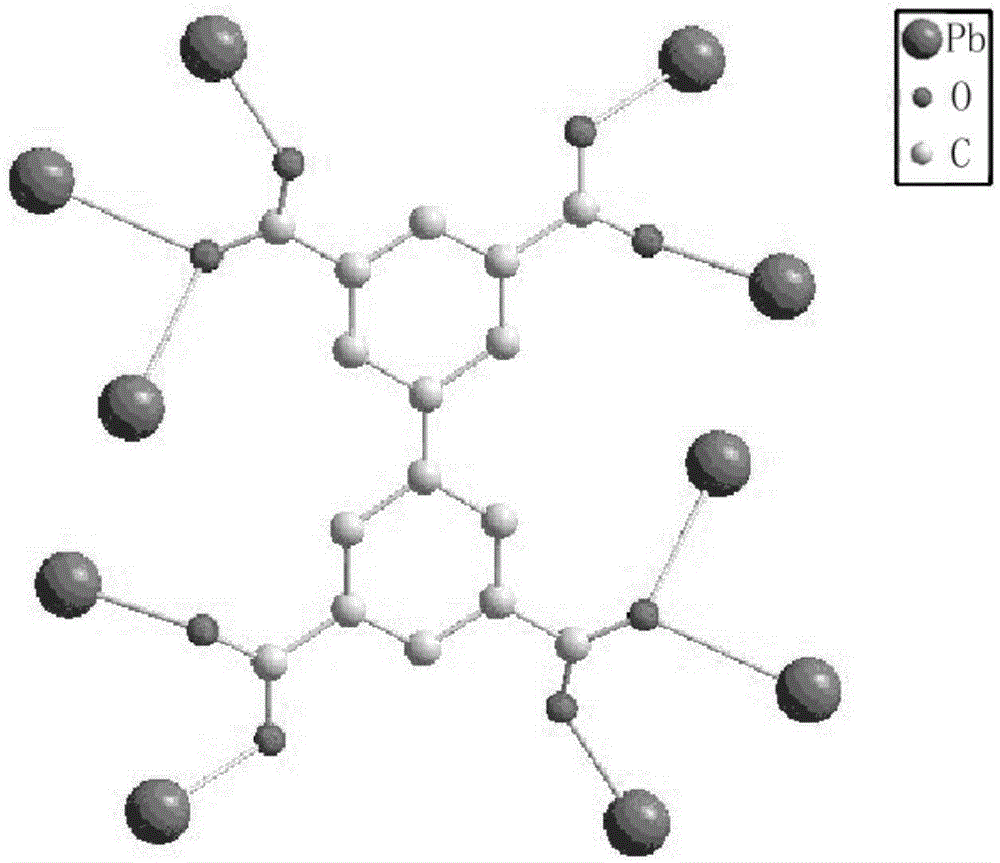

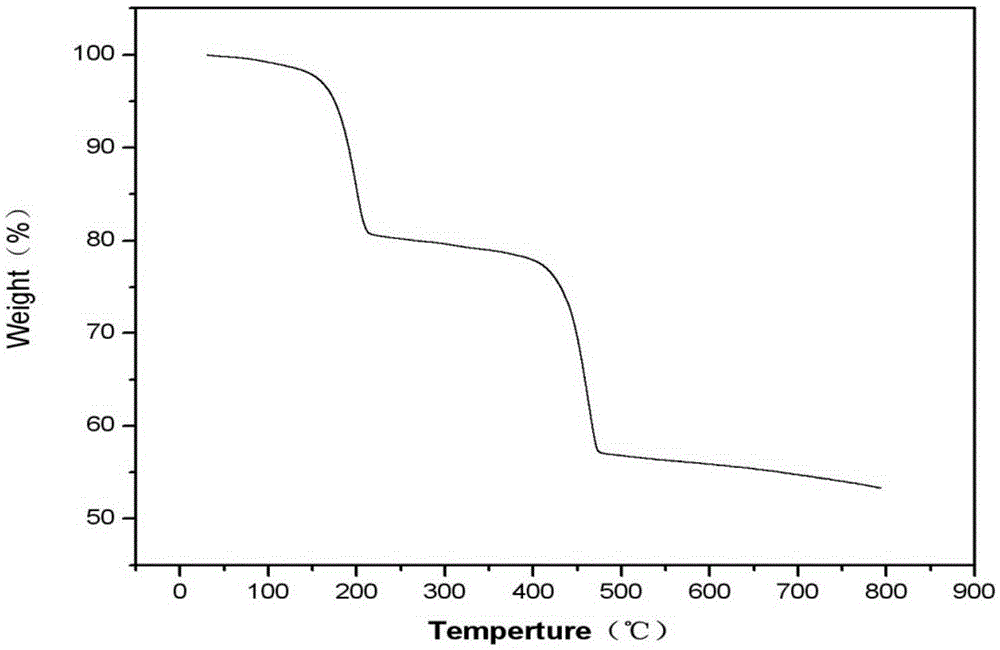

[0032] The results of X-ray diffraction analysis showed that metal-organic framework materials [Pb 2 (BPTC)(H 2 O) 2 ]·2H 2 O belongs to the triclinic crystal system, space group. Single crystal analysis shows that the metal-organic framework material has a three-dimensional pore structure without crossing inside the pore. It consists of two independent BPTC ligands and two different Pb(II) ion...

Embodiment 2

[0035] Example 2 The size-selective catalytic properties of metal-organic framework materials based on lead nitrate to catalyze silicocyanation reaction

[0036] The metal-organic framework material based on lead nitrate prepared in Example 1 was activated before use, and dried in a vacuum oven at 100° C. for 8 hours, as a catalyst for the following silicocyanation reaction.

[0037] The reaction is anhydrous and oxygen-free. Put 0.004mol of aromatic aldehyde and 5mg of catalyst into a 10mL Ceylon tube. After evacuating nitrogen for three times, ensure that there is no oxygen and water vapor in the Ceylon tube, and then transfer 5mL with a muffler. Dry degassed dichloromethane and 0.5 ml trimethylsilylcyanide (0.004 mol) were furnace and molecular sieve treated. The experimental temperature was 40°C, and the reaction process was monitored by gas chromatography. The conversion rate at different reaction times was as follows: Figure 4 shown. After 24 hours of reaction, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com