Feeding and discharging mechanism

A technology of blanking and material coding, applied in the field of loading and unloading mechanisms, can solve the problems of waste of resources, inability to match the efficiency of automated equipment, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

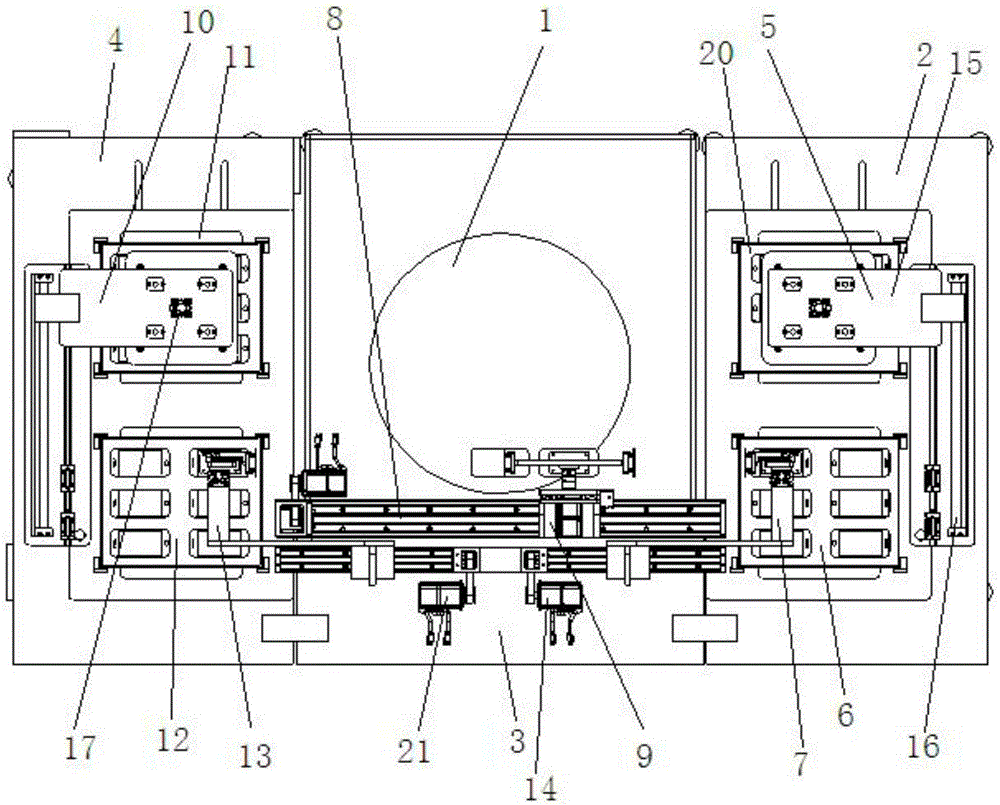

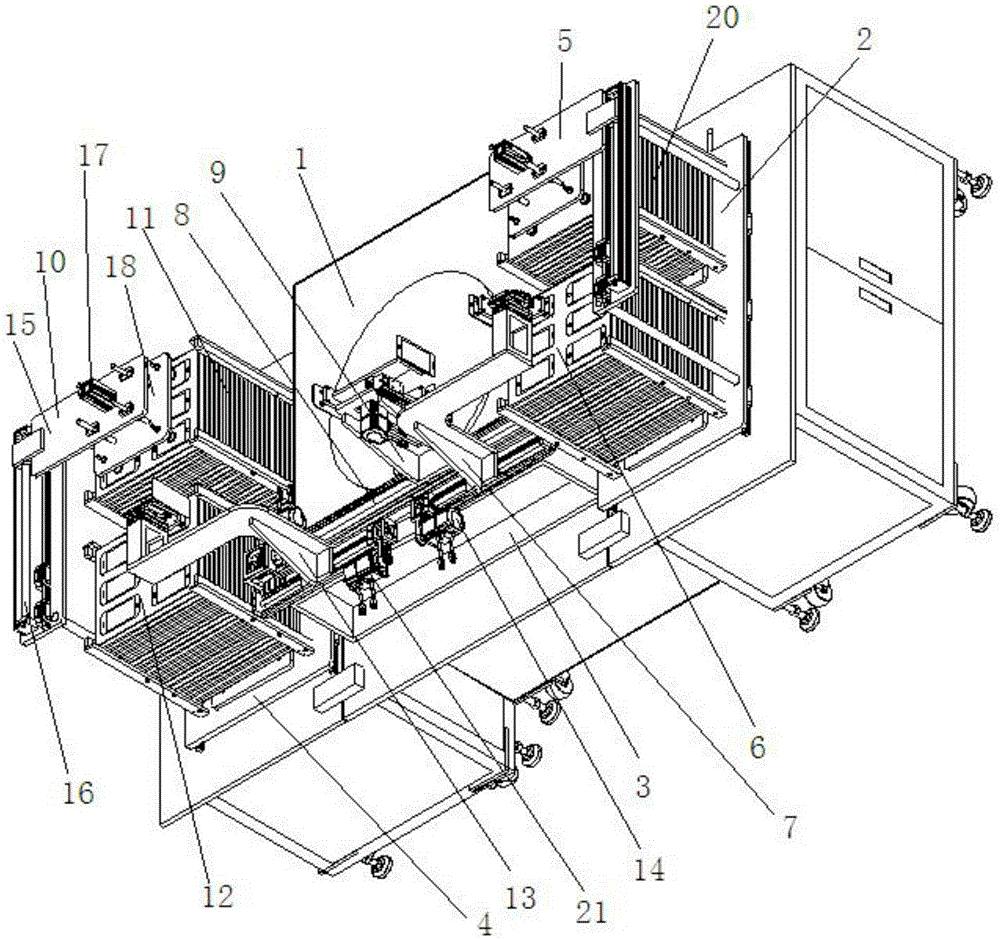

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] Such as Figure 1~Figure 2 As shown, a loading and unloading mechanism is characterized in that: it includes: a loading module 2, a retrieving module 3 and a unloading module 4 arranged around the detector 1 in sequence; Mechanism 5, a loading empty tray palletizing mechanism 20 and a loading palletizing mechanism 6 arranged directly below the loading empty tray pick-and-place mechanism 5, and the loading empty tray mechanism 6 is arranged on the loading empty tray Between the palletizing mechanism 20 and the reclaiming module 3, the reclaiming module 3 includes a first manipulator 7 for retrieving materials on the loading and palletizing mechanism 6, and is arranged on the displacement module 8 and is used for all The material platform 9 of the first manipulator 7 discharge and the second manipulator 13 for taking material on the detector 1 and putting it into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com