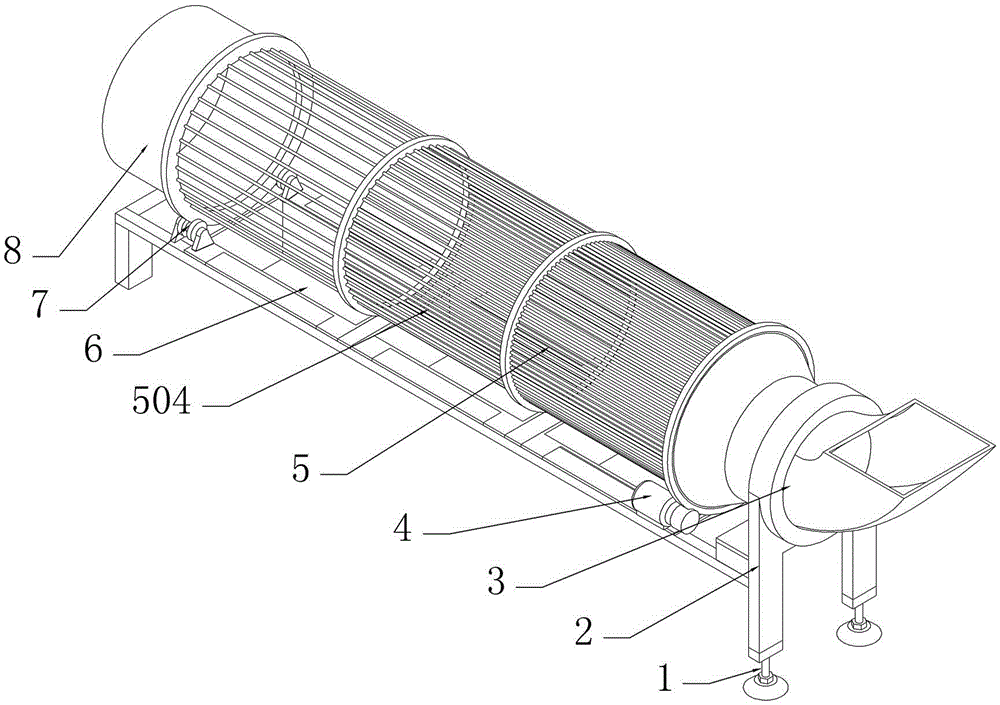

Classifying screening machine of stachys sieboldii

A technology of grading and screening, grass and stone silkworms, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of inability to ensure uniform thickness, different judgment standards, low efficiency, etc., to save manpower, save time, and easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The inclination angle of the screening drum 5 in Example 1 is 5°.

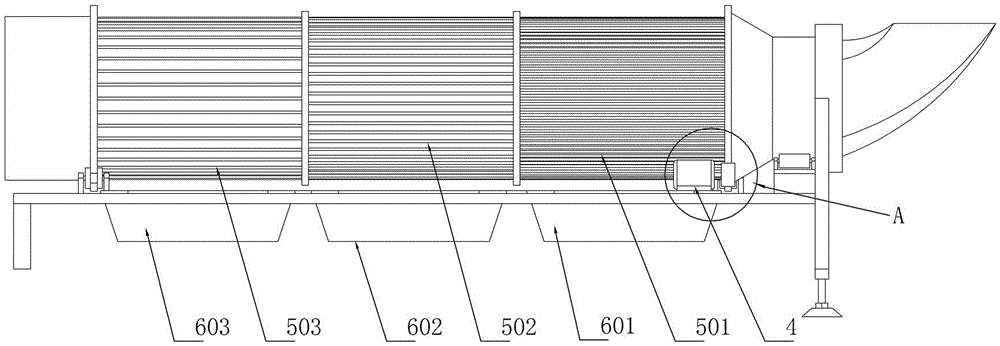

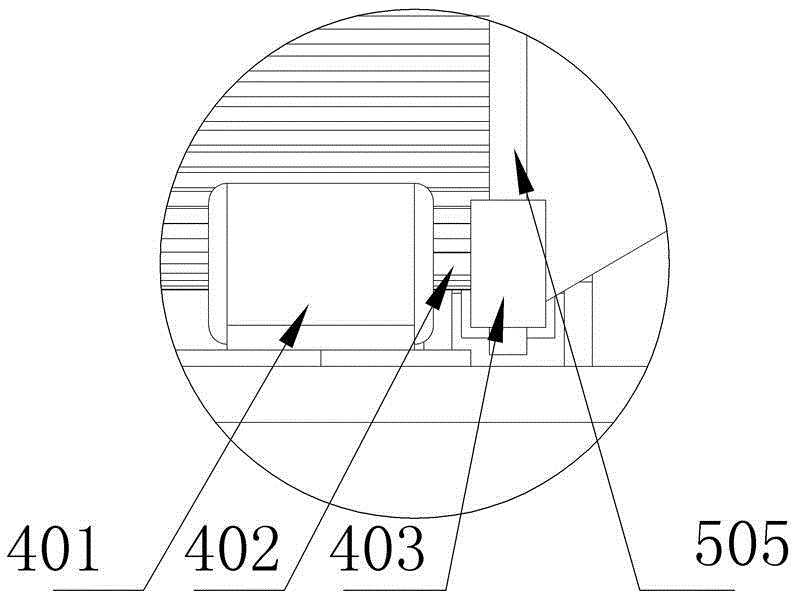

[0024] like Figure 4 As shown, the difference between Embodiment 2 and Embodiment 1 is that a transmission pulley 405 is provided on the rotating shaft 402, and a belt 404 is connected on the transmission pulley 405, and the belt 404 is connected with a driven pulley 406 provided outside the discharge port 8; The roller 7 is on the screening cylinder 5 and is located at the lower part of one side of the feed inlet 3; the inclination angle of the screening cylinder 5 is 10°.

[0025] The motor 401 rotates and then drives the driven gear 505 or the driven pulley 406 to rotate, so that the primary classifying screen 501, the secondary classifying screen 502 and the third stage classifying screen 503 rotate synchronously, and the grass and silkworms are fed from the feed port 3 , with the increase of the feed amount, the caddis worm moves towards the discharge port 8 under the rotation of the screening cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com