Magnetic ZnO@ZnFe2O4 compound optical catalyst and preparation method therefor and application thereof

A znfe2o4, composite light technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult recycling and reuse of materials, and achieve low cost, high chemical stability, and magnetic separation. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] S1: ZnFe 2 o 4 Preparation of:

[0030] Weigh 1.092gFeCl 3 ·6H 2 O solid and 0.272g ZnCl 2 Add the solid to 70mL of ethylene glycol, stir evenly, then add 2.312g of sodium acetate, continue to stir until uniform; transfer the mixed solution to a reaction kettle and react at 210°C for 72h, and after the reaction, ZnFe 2 o 4 Hollow nano-microspheres; separated by magnetic separation, washed five times with deionized water and absolute ethanol, and vacuum-dried at 60°C for 12 hours to obtain ZnFe 2 o 4 .

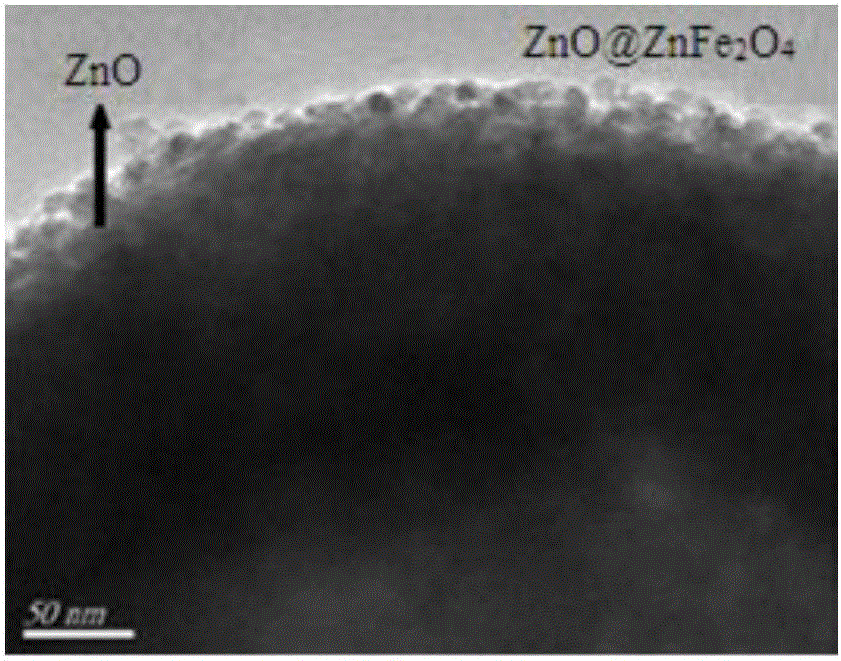

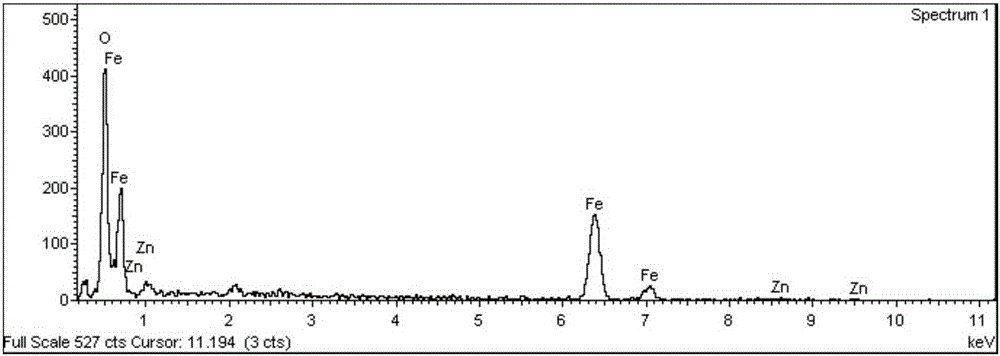

[0031] S2: ZnOZnFe 2 o 4 Preparation of:

[0032] Weigh 0.35gZnFe 2 o 4 Dissolve it in a beaker containing 50mL of absolute ethanol, then weigh 0.33g of zinc acetate and add it to the above beaker, transfer the above solution to a three-neck flask device, and vigorously stir and boil it in a water bath at 80°C; then weigh 0.03g of LiOH· h 2 O was added to 50mL of absolute ethanol, ultrasonicated for 30min, the solution was uniformly mixed and then added dro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com