Horizontal sedimentation tank with sludge pump house

A technology of advection sedimentation tank and sludge pump room, applied in sludge treatment, water/sludge/sewage treatment, sedimentation tank, etc. If the land area is too large and the treatment effect cannot be guaranteed, it can achieve the effect of uniformly achieving the sedimentation effect, increasing the utilization rate of pool capacity and improving the utilization rate of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

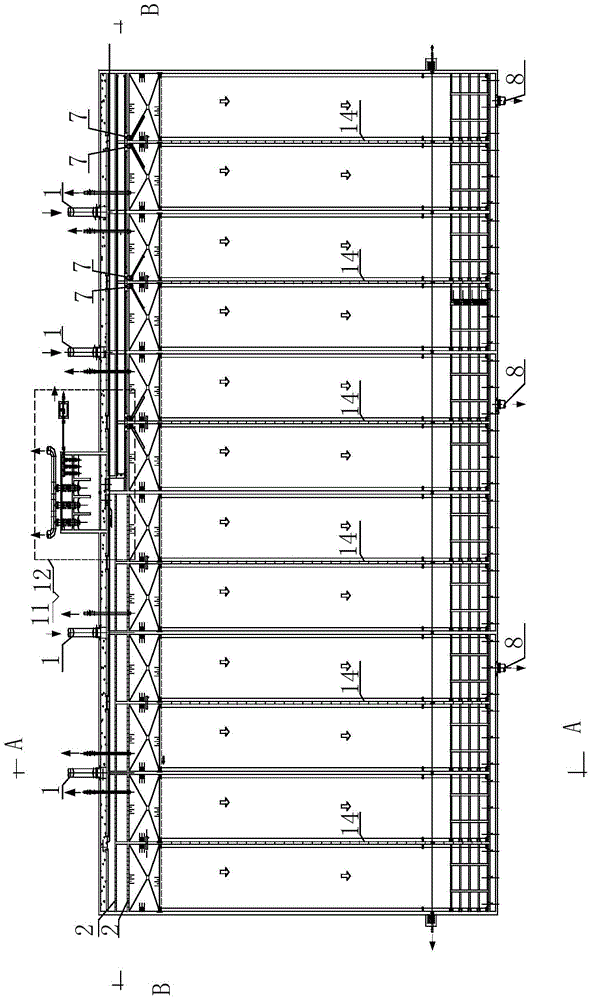

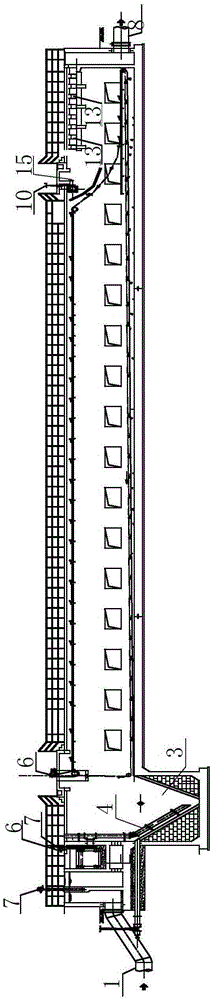

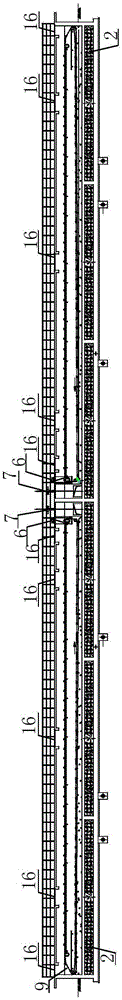

[0027] The purpose of the present invention is achieved through the following technical solutions: as Figure 1 ~ Figure 4 As shown, the advection settling tank with sludge pump room provided in this embodiment is grouped with several settling tank units that can be connected and separated, and each set of settling tank units is sequentially provided with a settling tank unit for inputting sewage to be treated secondary. The water inlet area, the sedimentation area for mud and water sedimentation and stratification, the mud discharge area for the discharge of sediment, and the water outlet area for the discharge of sedimentation water obtained after stratification; The sludge discharge tank 5 connected by the bucket 3, and the other end of the sludge discharge tank 5 is respectively connected to a sludge external return pump room 11 for external return and a residual sludge for discharge of excess sludge through the sludge discharge pipe 4 Pump room 12; both sides of the entra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com