Soft driving method of power MOSFET and circuit

A soft drive, MOS tube technology, applied in the direction of output power conversion devices, electrical components, etc., can solve the problems of not being a MOSFET drive circuit, large conduction loss, poor EMI performance, etc., to reduce EMI effects and reduce conduction. Loss, EMI reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

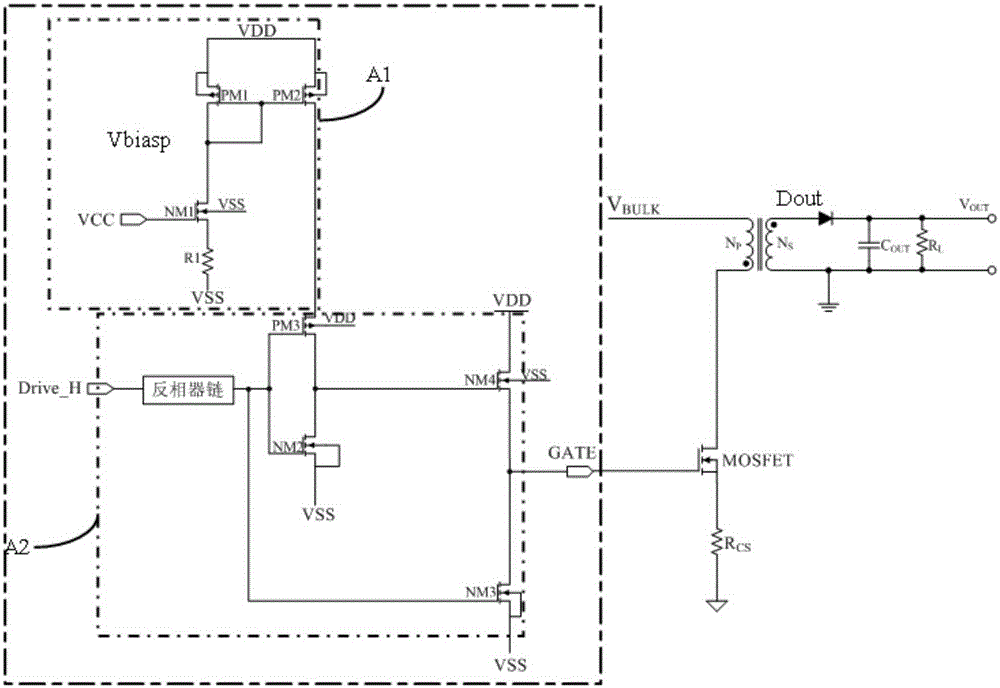

[0046] Such as Figure 6 As shown, it is a power MOSFET soft driving circuit diagram according to Embodiment 1 of the present invention. A soft drive circuit for power MOSFETs, comprising: a current bias unit A11, a drive chain unit A12 and a positive feedback current generation unit A13.

[0047] Current bias unit A11 and drive chain unit A12 and background technology figure 2 The circuit shown is the same, and only the number of each component is distinguished by adding 10 in front of it, so it will not be repeated here.

[0048]The positive feedback current generating unit A13 is composed of resistor R102, resistor R103, N-channel MOS transistor NM105, N-channel MOS transistor NM106, N-channel MOS transistor NM107, P-channel MOS transistor PM104, P-channel MOS transistor Tube PM105, P-channel MOS tube PM106, diode D1, logic NOT gate INV101, and logic NOT gate INV102. The first port of the resistor R102, the gate of the N-channel MOS transistor NM107, and the output term...

Embodiment 2

[0051] Such as Figure 9 As shown, it is a power MOSFET soft drive circuit diagram of the second embodiment of the present invention, including: a current bias unit A21, a drive chain unit A22 and a positive feedback current generation unit A23.

[0052] The current bias unit A21 is composed of a current mirror composed of P-channel MOS transistor PM201, P-channel MOS transistor PM202, and P-channel MOS transistor PM203. The input bias current Ibp_40u is mirrored by the internal bias current of the chip through the current mirror It is obtained that the gate and drain of the P-channel MOS transistor PM201, the gate of the P-channel MOS transistor PM202, the gate of the P-channel MOS transistor PM203 and the output terminal of the positive feedback current generating unit A23 are connected together, The source and substrate of the P-channel MOS transistor PM201, the source and substrate of the P-channel MOS transistor PM202, and the source, substrate and drain of the P-channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com