Shaped lithium-manganese soft package battery and manufacturing method thereof

A flexible packaging battery and manufacturing method technology, applied in electrode manufacturing, primary battery electrodes, battery pack components, etc., can solve problems such as safety accidents, ineffective pole pieces, and virtual welding, and improve service life and shape. The effect of good coincidence, convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] The manufacturing method of special-shaped lithium-manganese flexible packaging battery is as follows:

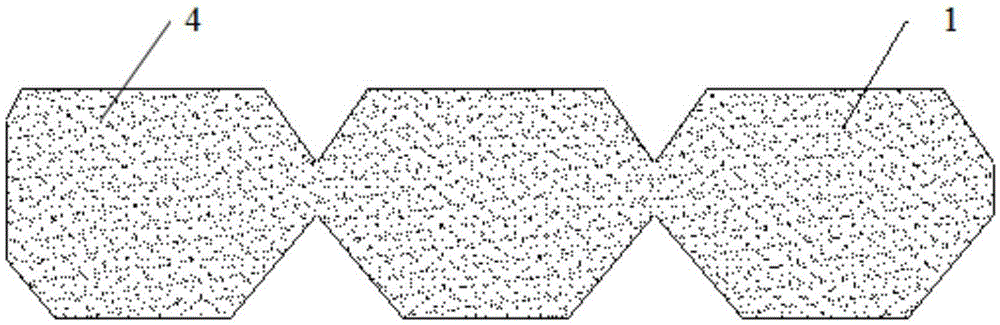

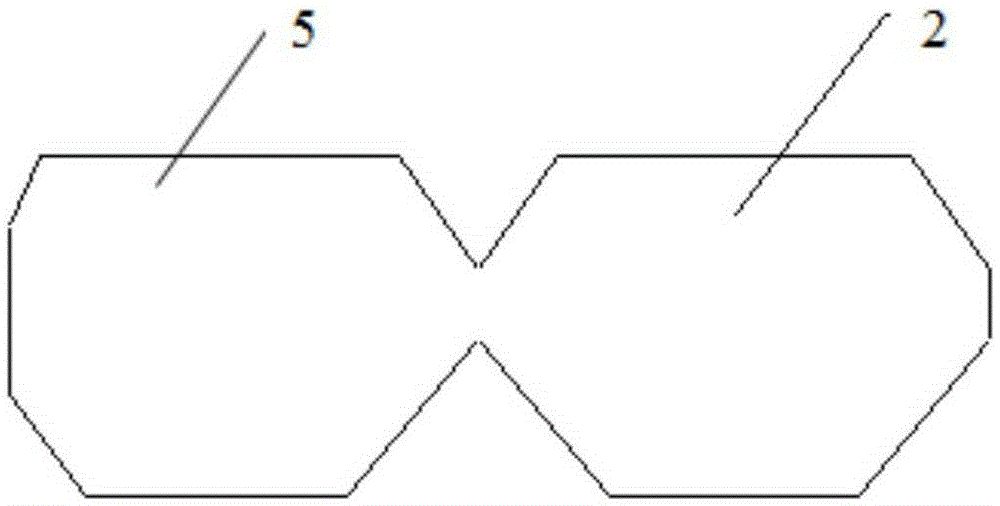

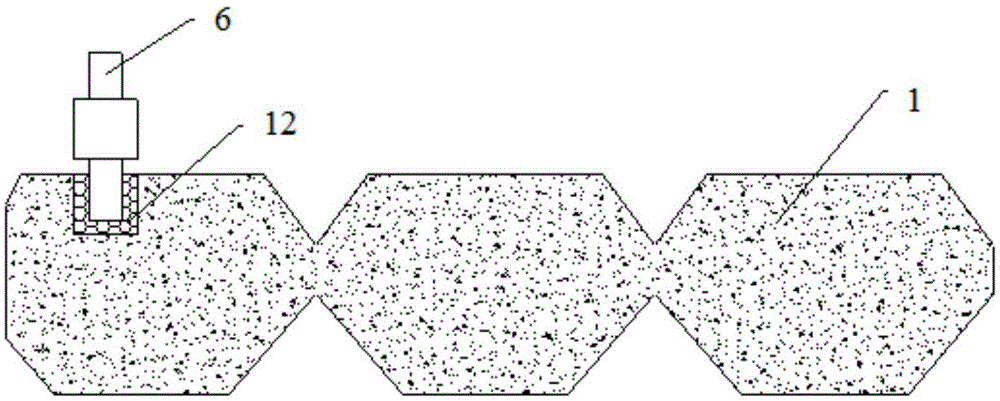

[0041] a. Positive electrode active material (lithium-manganese composite oxide, conductive agent, binder and pure water mixed), after stirring evenly, roll it into a film on a double-roller machine, after drying, press the film and aluminum mesh to form, and dry Finally, the positive pole piece is formed, and the positive pole piece is punched with a customized positive pole punching knife die to form a special-shaped positive pole piece 1 composed of a plurality of special-shaped positive pole unit pieces 4 connected. The shape of the special-shaped positive pole piece 4 is according to the shape of the electrical battery compartment Determined, it is the corresponding irregular octagon, such as figure 1 As shown, the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com