Preparation method for super-long titanium dioxide nanowire

A technology of titanium dioxide and nano-titanium dioxide, applied in the directions of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problem of not being able to meet the performance requirements well, and achieve the simple preparation method, low preparation cost and wide applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation method of the ultra-long titanium dioxide nanowires described in this embodiment specifically includes the following steps:

[0020] (1) Put nano-titanium dioxide powder in 10mol / L sodium hydroxide solution at a ratio of 20g / L, and stir electromagnetically to make it evenly mixed;

[0021] (2) Put the mixed solution obtained in step (1) into the reaction kettle, and react in an oil bath at 100°C (300r / min) for 24h;

[0022] (3) Centrifuge the reacted solution, wash the precipitate with deionized water until the pH is 9, and then wash with 0.3 mol / L dilute nitric acid until the pH is 7 to obtain ultra-long titanium dioxide nanowires.

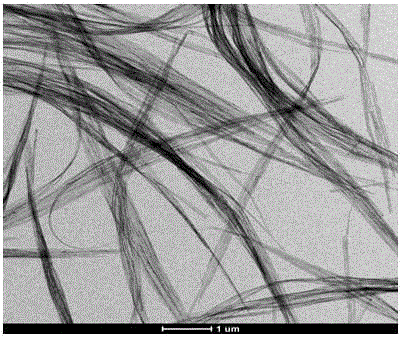

[0023] Depend on figure 1 It can be seen that the prepared titanium dioxide nanowires exist in the form of dispersed fibers, and most of the titanium dioxide nanowires shown in the figure have a length of more than 5 μm and a relatively high specific surface area.

Embodiment 2

[0025] The preparation method of the ultra-long titanium dioxide nanowires described in this embodiment specifically includes the following steps:

[0026] (1) Put nano-titanium dioxide powder in 12mol / L sodium hydroxide solution at a ratio of 30g / L, and stir electromagnetically to make it evenly mixed;

[0027] (2) Put the mixed solution obtained in step (1) into the reaction kettle, and react in an oil bath at 120°C (400r / min) for 22h;

[0028] (3) The reacted solution was centrifuged, and the precipitate was washed with deionized water until the pH was 9, and then washed with 0.1 mol / L dilute nitric acid until the pH was 7 to obtain ultra-long titanium dioxide nanowires.

Embodiment 3

[0030] The preparation method of the ultra-long titanium dioxide nanowires described in this embodiment specifically includes the following steps:

[0031] (1) Put nano-titanium dioxide powder in 8mol / L sodium hydroxide solution at a ratio of 40g / L, and stir it to make it evenly mixed;

[0032] (2) Put the mixed solution obtained in step (1) into the reaction kettle, and react in an oil bath at 140°C (500r / min) for 20h;

[0033] (3) The reacted solution was centrifuged, and the precipitate was washed with deionized water until the pH was 9, and then washed with 0.2 mol / L dilute nitric acid until the pH was 7 to obtain ultra-long titanium dioxide nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com