Original ecological food transport scheduling system and method

A scheduling method and original ecological technology, applied in the direction of instruments, data processing applications, logistics, etc., can solve the problems of users' decentralized transportation implementation requirements, and achieve the effect of good distribution effect, fast speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for dispatching original ecological food transportation, comprising the following steps:

[0044] Step 1. Information collection

[0045] Obtain all order information in the server database. For each order, extract the user ID, user credit points, product ID contained in the order, the weight of each product, the place of departure, the shipping destination, and the distance between each shipping destination. distance, and the weight of traffic conditions between destination and transport destination;

[0046] Step 2. Plan the route

[0047] Calculate the weight of each shipping destination, for a shipping destination, its weight Qa is:

[0048] Qa=Y1+Y2+...Yj+...+Yn,

[0049] Yj=C1+C2+...Ck+...+Cm,

[0050] Ck=αk×βk,

[0051] Yj is the order whose destination is Q, j is a natural number and 1≤j≤n, n is the order quantity of the destination Yj, Ck is the weight of a product in an order, k is a natural number and 1≤k≤m, m is the number of products in the o...

Embodiment 2

[0079] The material for making the bag is optimized, as follows:

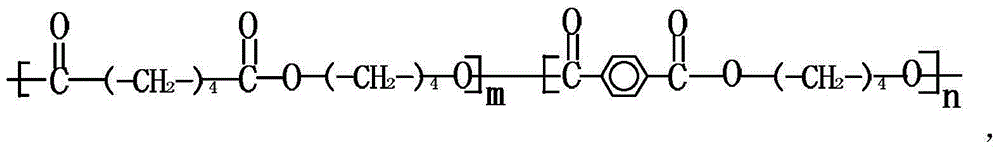

[0080] The degradable material is composed of the following raw materials by weight fraction: nano-scale aluminum oxide 1.5-5.5%, polylactic acid / propylene carbonate blend 2.5-4.5%, stearic acid coupling agent 1.8-3.2%, paraffin wax 5% ~6.5%, the balance is a degradable polymer; wherein the molecular formula of the degradable polymer is:

[0081]

[0082] In the formula, m is 15-25, and n is 10-20. The nano-level alumina is 6000-8000 mesh. The weight average molecular weight of the polylactic acid / propylene carbonate blend is 50,000-80,000. The thickness of the bag body is 0.02-0.08mm.

[0083] Regarding the composition of the packaging bag, the following sets of examples are given to illustrate various performance parameters of the bag body.

Embodiment a

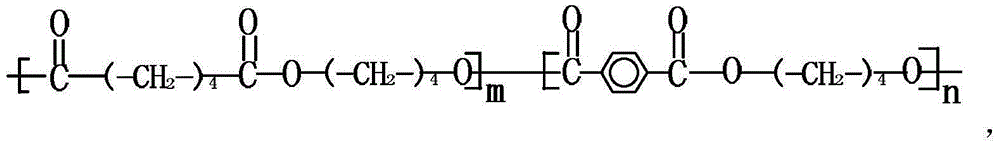

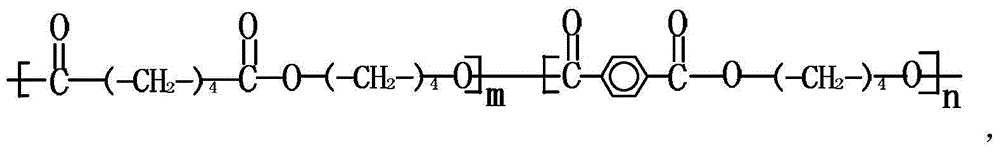

[0085] Nanoscale aluminum oxide 1.8%, polylactic acid / propylene carbonate blend 4.3%, stearic acid coupling agent 2.1%, paraffin 6.2%, and the balance is a degradable polymer; wherein the degradable polymer The molecular formula is:

[0086]

[0087] In the formula, m is 15-25, and n is 10-20. The nano-scale alumina is 6000-8000 mesh. The weight average molecular weight of the polylactic acid / propylene carbonate blend is 50,000-80,000. The thickness of the bag body is 0.04mm.

[0088] The tensile strength is 45.3MPa, the elongation is 445.3%, and the 6-week degradation rate is 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com