High-temperature-resistance and freezing-resistance test device for concrete

A test device and high-temperature-resistant technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of cumbersome temperature adjustment, difficulty in obtaining test data, and inability to ensure uniform temperature, etc., to achieve the effect of accurate test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

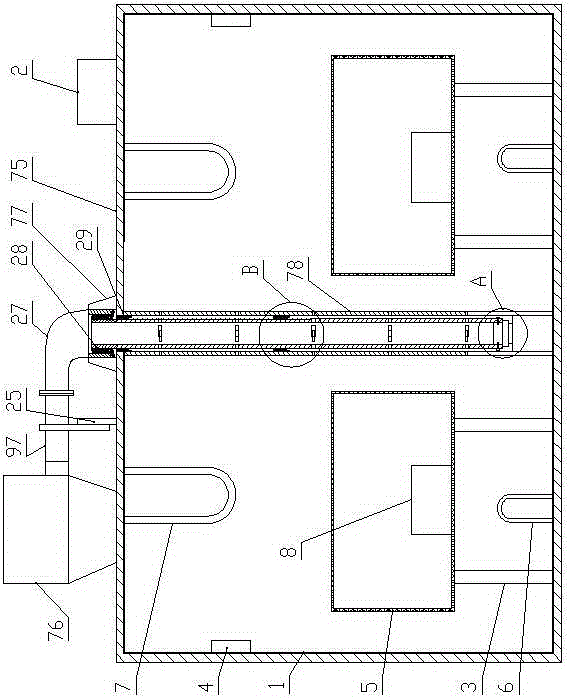

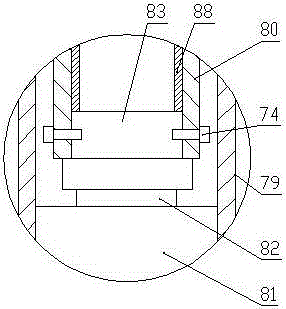

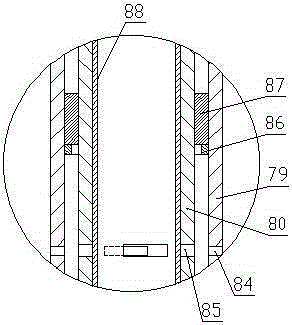

[0030] Such as Figure 1-Figure 9 As shown, the concrete high temperature resistance and frost resistance test device of the present invention includes a closed box body 75. The inner surface of the closed box body 75 is provided with an insulation layer 1, and the top of the closed box body 75 is provided with a controller 2 and a cooling air supply mechanism 76. And the mounting frame 77, the closed box 75 is provided with an air volume rotation adjustment mechanism 78 and at least four freeze-thaw test systems evenly arranged around the air volume rotation adjustment mechanism 78.

[0031] Each freeze-thaw test system includes a support 3 located at the bottom of the closed box 75 and a temperature sensor 4 located on the upper part of the side wall of the closed box 75. The support 3 is equipped with a test box 5 made of steel wire mesh (the steel mesh has The permeability is strong, so that the temperature of each surface of the concrete specimen is basically the same), the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com