Diaphragm coupling type extrinsic fiber fabry-perot sensor probe

A sensor probe, coupled technology, used in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems such as reducing the static pressure sensitivity of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

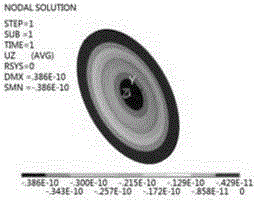

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0021] The membrane-coupled extrinsic fiber Fabry-Perot sensor probe of the present invention, such as figure 1 As shown, it includes a supporting sleeve 1, an optical fiber ferrule mounting part 2, an optical fiber ferrule 3 set in the supporting sleeve 1 through the optical fiber ferrule mounting part 2, and an optical fiber 4 set in the optical fiber mounting hole of the optical fiber ferrule 3 The front end of the optical fiber ferrule 3 is coated with a first reflective film 5, the first reflective film 5 at the front end of the optical fiber ferrule 3 is located inside the support sleeve 1, and the front end of the support sleeve 1 is fixed with a second reflective film 6 , the second reflective film 6 has the same reflectivity as the first reflective film 5, thereby obtaining a sensor operating curve with a larger linear modulation area, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com