Green lubricating oil composite additive for methanol fuel internal combustion engine, lubricating oil using the composite additive and production method thereof

A technology of methanol fuel and production method, which is applied in the field of lubricating oil, can solve the problems of sludge production in engine cylinders, corrosion of engine-related components, emulsification, etc., and achieve the effect of major environmental benefits and practical application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

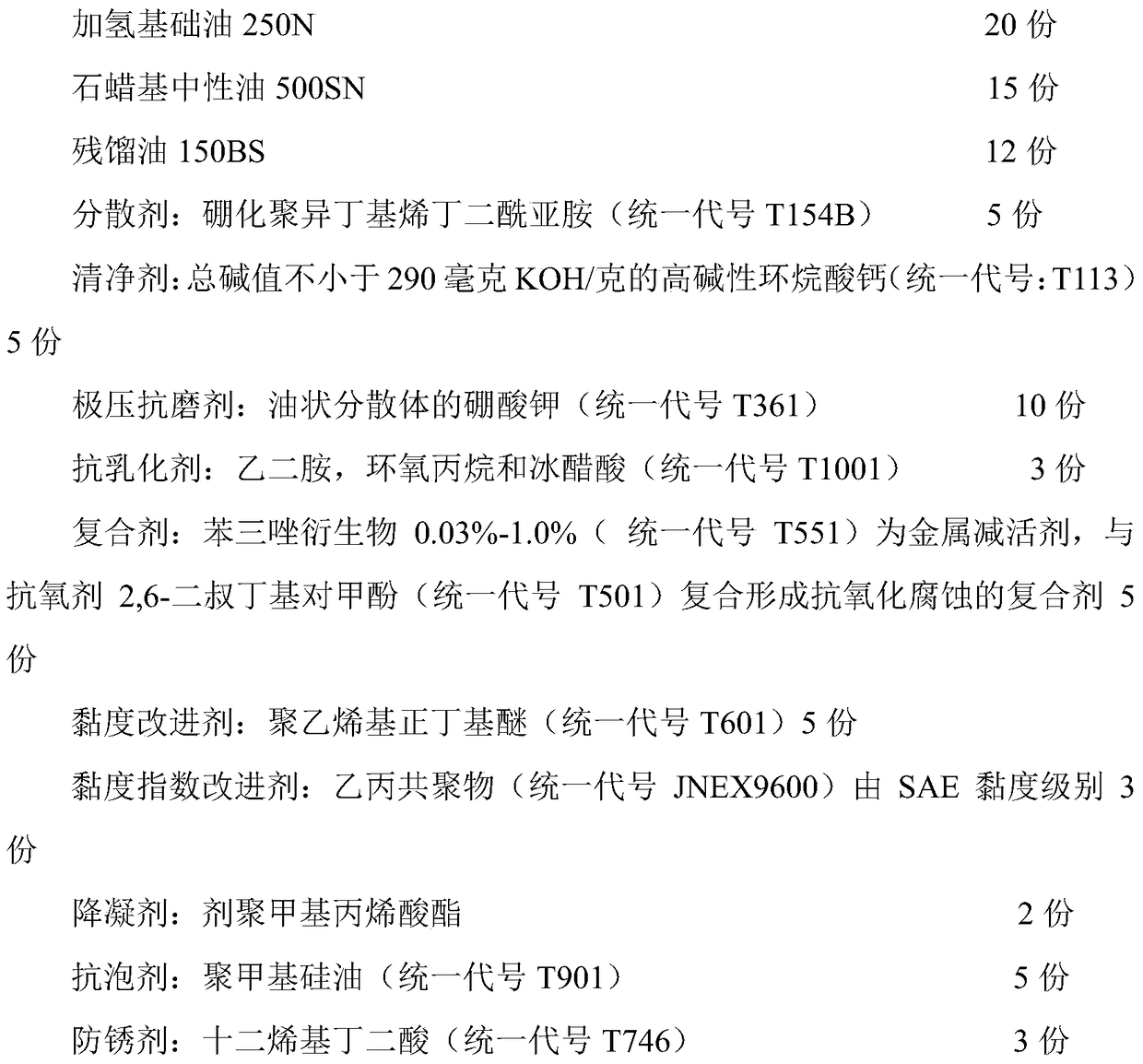

[0036] A kind of lubricating oil, used raw material and weight fraction thereof are as follows:

[0037]

[0038] The production method of this embodiment is: Step 1: Add 20 parts of hydrogenated base oil 250N, 15 parts of paraffin-based neutral oil 500SN, and 12 parts of residual distillate oil 150BS into the material tank according to the parts by weight, and stir and mix under normal temperature and pressure for 20 minute;

[0039] Step 2: Add 5 parts of detergent, 5 parts of dispersant and 5 parts of compounding agent in parts by weight, and stir and mix for 20 minutes at normal temperature and pressure;

[0040] Step 3: Add 5 parts of viscosity improver and 3 parts of viscosity index improver according to parts by weight, stir and mix for 30 minutes at normal temperature and pressure;

[0041] Step 4: Add 10 parts of extreme pressure anti-wear agent, 3 parts of anti-emulsifier, 2 parts of pour point depressant, 5 parts of anti-foaming agent, 3 parts of anti-rust agent...

Embodiment 2

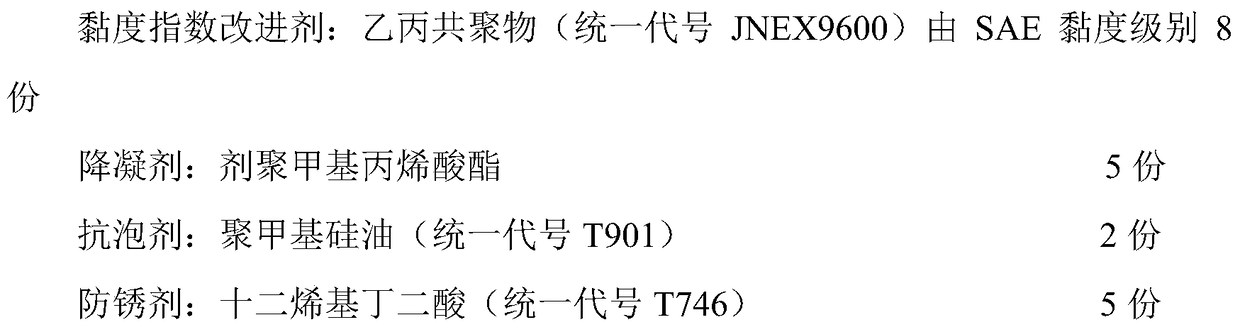

[0044] The difference from Example 1 is that

[0045]

[0046] The production method of present embodiment is identical with embodiment 1

[0047] It can be known through experiments that the present invention has good lubricating and anti-wear effects, reduces friction and wear, improves mechanical properties, possesses the required features of the above methanol gasoline engine, ensures the normal operation of the methanol gasoline engine, lower friction and wear and relatively Long service life. The invention does not use compounds containing chlorine, sulfur and phosphorus, and meets the standard requirements of environment-friendly and green oil treatment technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com