A kind of improver for lubricating oil and preparation process thereof

A preparation process and improver technology, applied in the field of lubricating oil improver and its preparation process, can solve the problems of unsuitable for multi-grade internal combustion engine oil, limited application range, poor low temperature fluidity, etc., and achieve good shear stability, anti-corrosion Excellent shear performance and improved oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

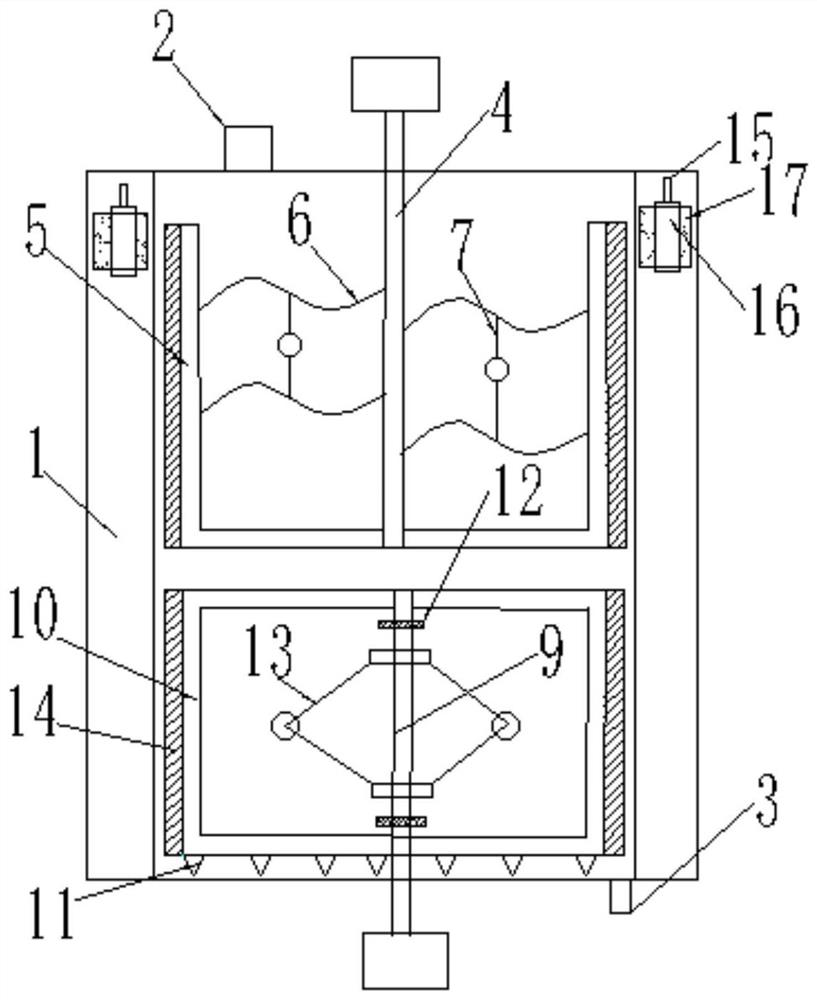

Method used

Image

Examples

Embodiment 1

[0033] An improver for lubricating oil, comprising the following components:

[0034] The mass fraction is 0.4% of star-shaped hydrogenated styrene diene copolymer and 10% of polyisobutylene, and the rest is base oil. Among them, the molecular weight of star-shaped hydrogenated styrene diene copolymer is 80,000-400,000; the molecular weight of polyisobutylene is 200-5,000.

[0035] A preparation process for a lubricating oil improver, comprising the following steps:

[0036] S1. Put the star-shaped hydrogenated styrene diene copolymer with the above mass fraction into the base oil with the above mass fraction at 110°C under a nitrogen atmosphere, heat and stir until the two are completely fused to form a flowing transparent glue; and, Before inputting, cut and crush the star-shaped hydrogenated styrene diene copolymer solid to make it dissolve quickly;

[0037] S2. Cool down the transparent glue with the above mass fraction to 50° C., put polyisobutylene into it, keep warm a...

Embodiment 2

[0040] An improver for lubricating oil, comprising the following components:

[0041] The mass fraction is 0.08% of star-shaped hydrogenated styrene diene copolymer and 30% of polyisobutylene, and the rest is base oil. Among them, the molecular weight of star-shaped hydrogenated styrene diene copolymer is 80,000-400,000; the molecular weight of polyisobutylene is 200-5,000.

[0042] A preparation process for a lubricating oil improver, comprising the following steps:

[0043]S1. Put the star-shaped hydrogenated styrene diene copolymer with the above mass fraction into the base oil with the above mass fraction at 120°C under a nitrogen atmosphere, heat and stir until the two are completely fused to form a flowing transparent glue; and, Before inputting, cut and crush the star-shaped hydrogenated styrene diene copolymer solid to make it dissolve quickly;

[0044] S2. Cool down the above mass fraction of transparent glue to 60° C., put polyisobutylene into it, heat and stir unt...

Embodiment 3

[0047] An improver for lubricating oil, comprising the following components:

[0048] The mass fraction is 1% star-shaped hydrogenated styrene diene copolymer and 60% polyisobutylene, and the rest is base oil. Among them, the molecular weight of star-shaped hydrogenated styrene diene copolymer is 80,000-400,000; the molecular weight of polyisobutylene is 200-5,000.

[0049] A preparation process for a lubricating oil improver, comprising the following steps:

[0050] S1. Put the star-shaped hydrogenated styrene diene copolymer with the above mass fraction into the base oil with the above mass fraction at 130°C under a nitrogen atmosphere, heat and stir until the two are completely fused to form a flowing transparent glue; and, Before inputting, cut and crush the star-shaped hydrogenated styrene diene copolymer solid to make it dissolve quickly;

[0051] S2. Cool down the transparent glue with the above mass fraction to 70° C., put polyisobutylene into it, keep warm and stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com