Preparation method and application of a light-responsive smart imprinted mesoporous material

A mesoporous material, light-responsive technology, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of uncompetitive adsorption capacity, limited commercial application, etc., to solve the problem of difficult elution and repeated use. The effect of many times and significant separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

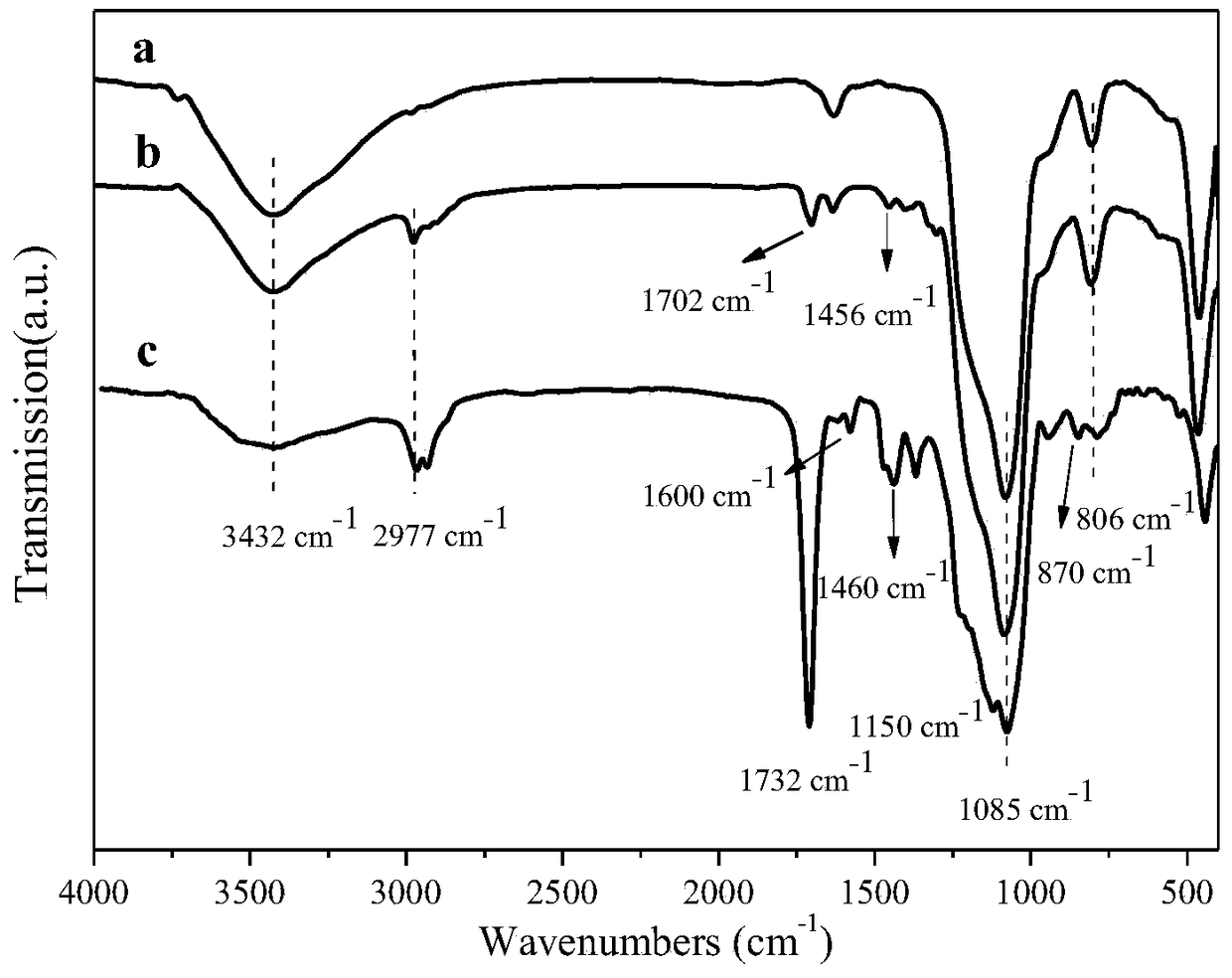

[0031] (1) Preparation of photosensitive monomer MPABA

[0032] Take 2.75g of 4-aminobenzoic acid and dissolve in 20mL of 5M concentrated hydrochloric acid, then add 10mL of a solution containing 1.6g of sodium nitrite into it, control the temperature with an ice-water bath, and continue stirring for 1h after the yellow color appears. The resulting solution was then added to 50 mL of a solution containing 1.89 g of phenol and 6 g of sodium hydroxide, placed in an ice-water bath for 2 h, and then diluted with 100 mL of deionized water. Add an appropriate amount of sodium hydroxide and concentrated hydrochloric acid to wash and remove impurities, then wash with excess ethyl acetate three times, dry and spin evaporate. The crude product was recrystallized to obtain 4-[(4-hydroxy)phenylazo]benzoic acid (HPABA).

[0033] 2.5 g of the HPABA synthesized above, 0.15 g of dimethylaminopyridine, 3.2 g of methacrylic anhydride and 1.386 mL of triethylamine were dissolved in 150 mL of TH...

Embodiment 2

[0051] (1) Preparation of photoresponsive imprinted mesoporous materials

[0052] The synthesis of the photosensitive monomer MPABA and the modification of the matrix material are as described in Example 1.

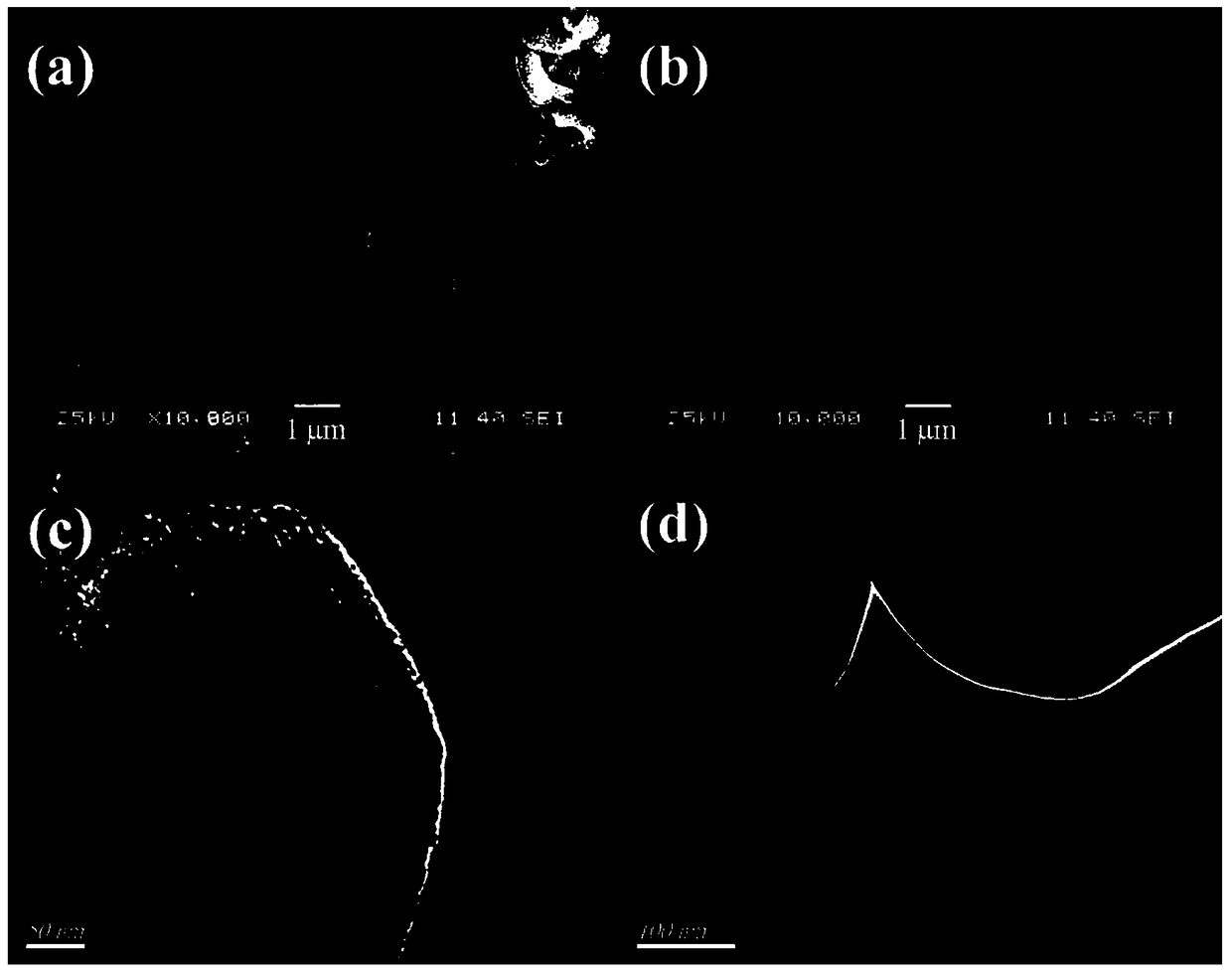

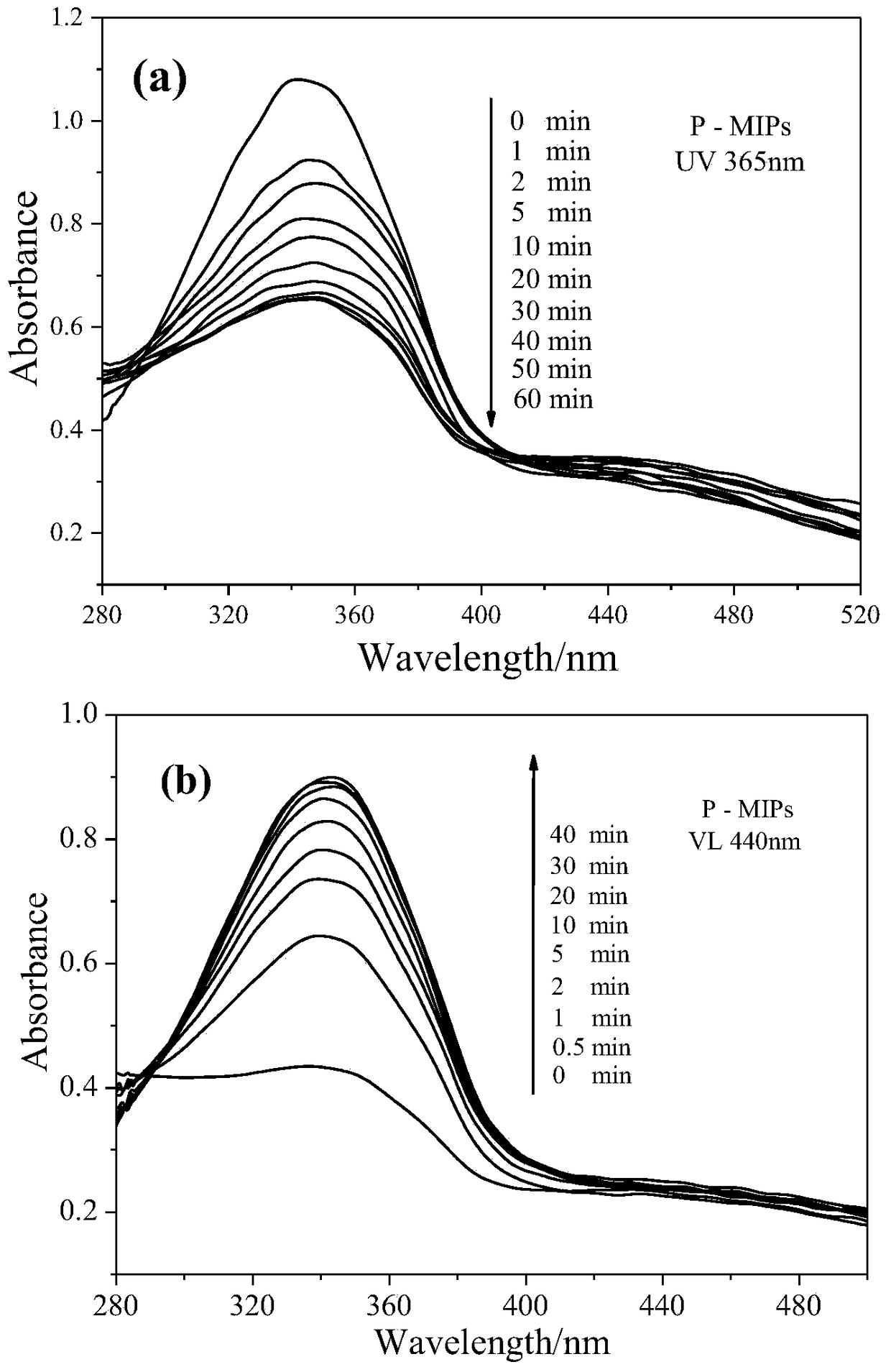

[0053] First, 22.8 mg of bisphenol A and 74.4 mg of MPABA were mixed in 10 mL of methanol / DMSO (4:1, v / v) for self-assembly, and placed in a dark place for 12 hours. Then take 50mg SBA-15-MPS and disperse in 30mL methanol solution, add self-assembly solution and 198mg EGDMA. Then the mixture was placed in a water bath, heated to 65°C, and 10 mg of AIBN was added, deoxygenated with nitrogen for 30 min, sealed, and magnetically stirred for 24 h in the dark. After the polymerization reaction, the polymer was collected by filtration, washed three times with methanol and DMSO successively, and dried in vacuum to constant weight for later use.

[0054] The above-mentioned dried polymer was dispersed in 50 mL DMSO, irradiated with ultraviolet light (365 nm) for 2 h under stirr...

Embodiment 3

[0060] (1) Preparation of photoresponsive imprinted mesoporous materials

[0061] The synthesis of the photosensitive monomer MPABA and the modification of the matrix material are as described in Example 1.

[0062] First, 11.4 mg of bisphenol A and 37.2 mg of MPABA were mixed in 10 mL of methanol / DMSO (4:1, v / v) for self-assembly, and placed in a dark place for 12 hours. Then take 50mg SBA-15-MPS and disperse in 30mL methanol solution, add self-assembly solution and 50mg EGDMA. Then the mixture was placed in a water bath, heated to 65°C, and 5 mg of AIBN was added, deoxygenated with nitrogen for 30 min, sealed, and magnetically stirred for 24 h in the dark. After the polymerization reaction, the polymer was collected by filtration, washed three times with methanol and DMSO successively, and dried in vacuum to constant weight for later use.

[0063] The above-mentioned dried polymer was dispersed in 50 mL DMSO, irradiated with ultraviolet light (365 nm) for 2 h under stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com