Anchoring mortar and application method thereof

A mortar and anchoring technology, applied in the field of anchoring mortar, can solve problems such as endangering traffic safety, railway line conduction, loss of communication signals, etc., to improve cohesive strength and tensile strength, good dispersion and film-forming properties, and increase early The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

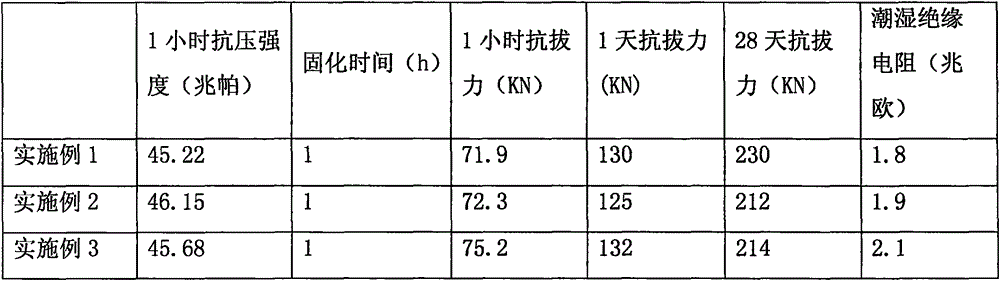

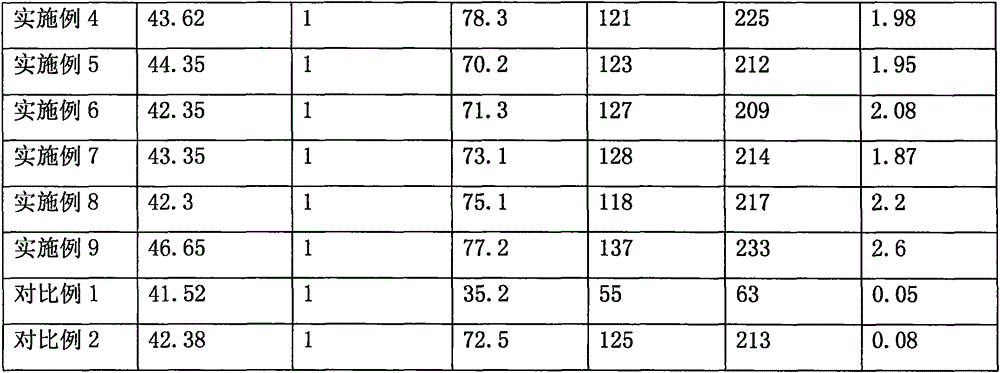

Examples

Embodiment 1

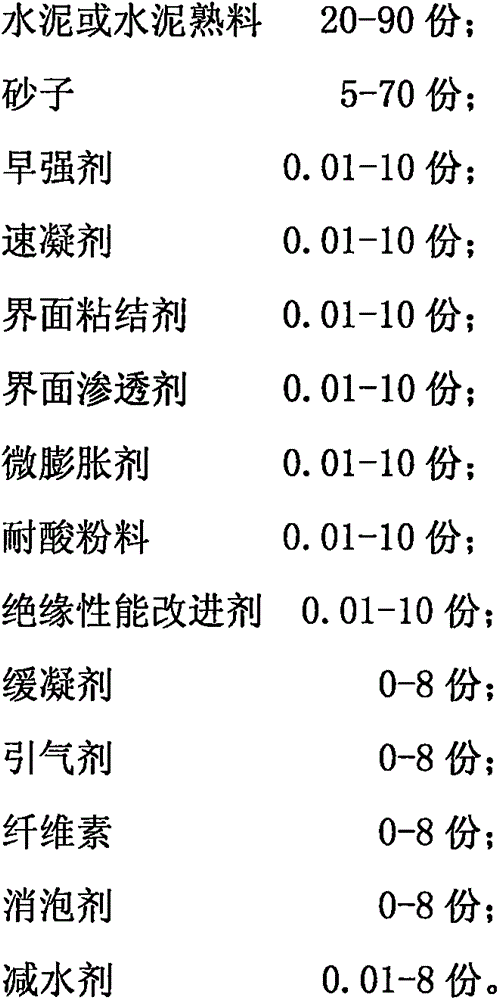

[0041] Raw material components:

[0042] Sulphoaluminate cement: 32 kg;

[0043] 52.5 kg of sand;

[0044] Early strength agent: 0.3 kg of sodium carbonate;

[0045] Accelerator: 0.2 kg of lithium nitrate;

[0046] Interface adhesive: 3 kg of acrylic resin latex powder;

[0047] Interface penetrating agent: sodium silicate 0.5 kg;

[0048] Micro expansion agent: 3.2 kg of gypsum, 2.4 kg of quicklime;

[0049] Acid-resistant powder: 3 kg of basalt rock powder;

[0050] Insulation performance improver: 2 kg of leucine;

[0051] Additional functional additives to adjust workability and setting time:

[0052] Retarder: 0.2 kg;

[0053] Air-entraining agent: 0.1 kg;

[0054] Cellulose: 0.1 kg;

[0055] Defoamer: 0.2 kg;

[0056] Water reducing agent: 0.3 kg.

[0057] Instructions:

[0058] Mortar preparation:

[0059] 1) After weighing the above-mentioned raw materials by weight, put the sulphoaluminate cement and sand in a dry powder mixer and stir evenly, and then m...

Embodiment 2

[0066] Raw material components:

[0067] Sulphoaluminate cement: 32 kg;

[0068] Sand: 52.5 kg;

[0069] Early strength agent: 0.3 kg of sodium carbonate;

[0070] Accelerator: 0.2 kg of lithium nitrate;

[0071] Interface adhesive: 3 kg of acrylic resin latex powder;

[0072] Interface penetrating agent: sodium silicate 0.5 kg;

[0073] Micro expansion agent: 3.2 kg of gypsum, 2.4 kg of quicklime;

[0074] Acid-resistant powder: 3 kg of basalt rock powder;

[0075] Insulation performance improver: 2 kg of serine;

[0076] Additional functional additives to adjust workability and setting time:

[0077] Retarder: 0.2 kg;

[0078] Air-entraining agent: 0.1 kg;

[0079] Cellulose: 0.1 kg;

[0080] Defoamer: 0.2 kg;

[0081] Water reducing agent: 0.3 kg.

[0082] Using method: with embodiment 1.

Embodiment 3

[0084] Raw material components:

[0085] Sulphoaluminate cement: 32 kg;

[0086] Sand: 52.5 kg;

[0087] Early strength agent: 0.3 kg of sodium carbonate;

[0088] Accelerator: 0.2 kg of lithium nitrate;

[0089] Interface adhesive: 3 kg of acrylic resin latex powder;

[0090] Interface penetrating agent: sodium silicate 0.5 kg;

[0091] Micro expansion agent: 3.2 kg of gypsum, 2.4 kg of quicklime;

[0092] Acid-resistant powder: 3 kg of basalt rock powder;

[0093] Insulation performance improver: barium oxide 2 kg;

[0094] Additional functional additives to adjust workability and setting time:

[0095] Retarder: 0.2 kg;

[0096] Air-entraining agent: 0.1 kg;

[0097] Cellulose: 0.1 kg;

[0098] Defoamer: 0.2 kg;

[0099] Water reducing agent: 0.3 kg.

[0100] Using method: with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com