Forming method for glass antifogging coating

An anti-fog coating and glass technology, which is applied in the field of polymer materials, can solve the problems of low anti-fog effect, low effect of water and oil pollution, etc., achieve good self-cleaning performance, and improve the use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

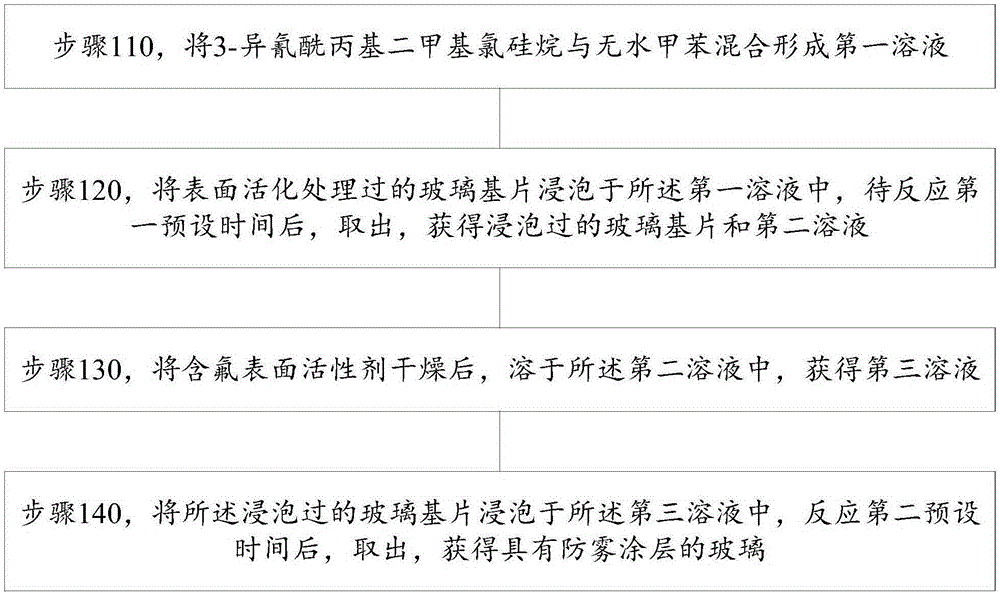

Method used

Image

Examples

example 1

[0053] Put the glass substrate into the beaker, add the mixed washing solution of hydrogen peroxide and concentrated sulfuric acid to the beaker, and stop heating when no bubbles are generated in the beaker. Take out the glass substrate and cool it down to room temperature, put it into deionized water, wash it ultrasonically, and dry it in vacuum to obtain the treated substrate, which is ready for use.

[0054] With anhydrous toluene as solvent, the weight ratio is 50%, the preparation 3-isocyanatopropyl dimethyl chlorosilane (ICPDMS) solution, ICPDMS weight ratio is 40%, the glass substrate after the treatment is soaked in the ICPDMS solution , at room temperature, vacuum anhydrous and oxygen-free treatment, react for 24 hours, and take it out.

[0055] Anhydrous MgSO is placed in the fluorosurfactant of 10% by weight, the fluorosurfactant is dried, and then the dried fluorosurfactant is dissolved in the solution after the reaction in the above steps, and then Soak the glass...

example 2

[0057] Put the glass substrate into the beaker, add the mixed washing solution of hydrogen peroxide and concentrated sulfuric acid to the beaker, and stop heating when no bubbles are generated in the beaker. Take out the glass substrate and cool it down to room temperature, put it into deionized water, wash it ultrasonically, and dry it in vacuum to obtain the treated substrate, which is ready for use.

[0058] With anhydrous toluene as solvent, the weight ratio is 70%, the preparation 3-isocyanatopropyl dimethyl chlorosilane (ICPDMS) solution, ICPDMS weight ratio is 20%, the glass substrate after the treatment is soaked in the ICPDMS solution , at room temperature, vacuum anhydrous and oxygen-free treatment, react for 24 hours, and take it out.

[0059] Anhydrous MgSO is placed in the fluorosurfactant of 10% by weight, the fluorosurfactant is dried, and then the dried fluorosurfactant is dissolved in the solution after the reaction in the above steps, and then Soak the glass...

example 3

[0061] Put the glass substrate into the beaker, add the mixed washing solution of hydrogen peroxide and concentrated sulfuric acid to the beaker, and stop heating when no bubbles are generated in the beaker. Take out the glass substrate and cool it down to room temperature, put it into deionized water, wash it ultrasonically, and dry it in vacuum to obtain the treated substrate, which is ready for use.

[0062] With anhydrous toluene as solvent, the weight ratio is 60%, the preparation 3-isocyanatopropyl dimethyl chlorosilane (ICPDMS) solution, ICPDMS weight ratio is 20%, the glass substrate after the treatment is soaked in the ICPDMS solution , at room temperature, vacuum anhydrous and oxygen-free treatment, react for 24 hours, and take it out.

[0063] Anhydrous MgSO is placed in the fluorine-containing surfactant of 20% by weight, the fluorine-containing surfactant is dried, and then the dried fluorine-containing surfactant is dissolved in the solution after the reaction in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com