Forging method for reducing proportion of tiny crack defects of bearing

A technology of tiny cracks and defects, applied in the field of bearing forging, can solve the problems of easy defects in forgings and the influence of changes in the streamline of the material section, and achieve the effects of deformation coordination, improving reliability and increasing the pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

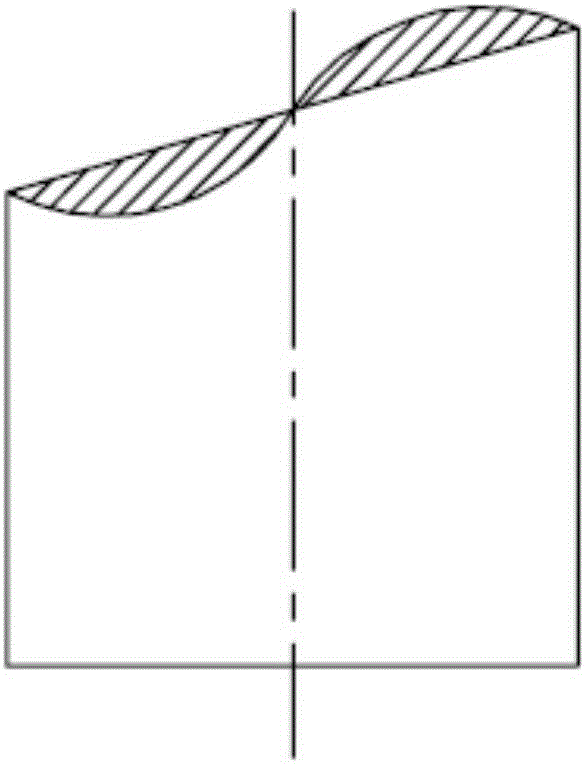

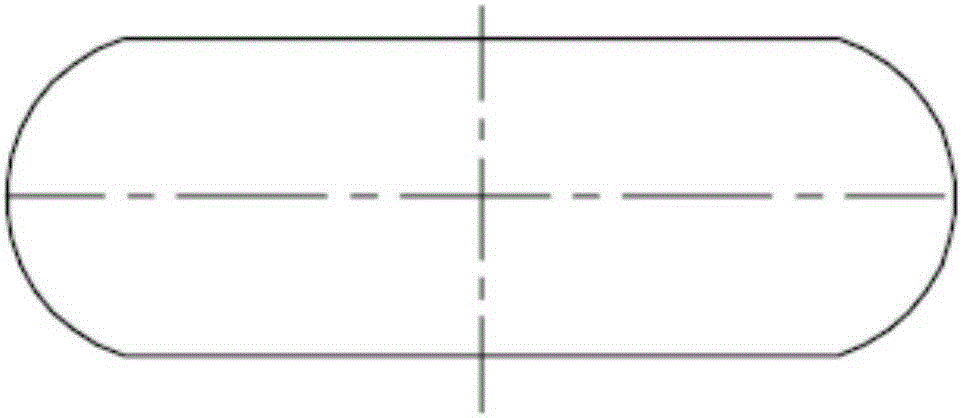

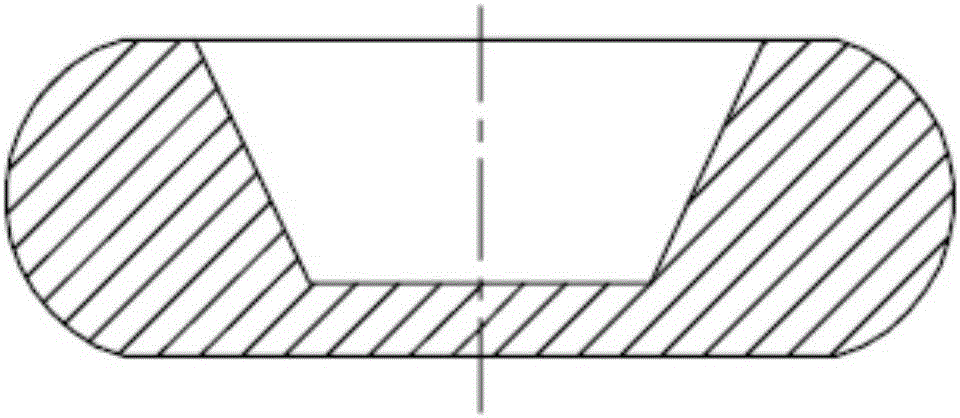

[0021] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 To illustrate this embodiment, a forging method for reducing the proportion of bearing micro-crack defects described in this embodiment is a free punching method without a die, which is specifically carried out according to the following steps:

[0022] Step 1. Upsetting the material section: use a 450Kg air hammer to hammer the material section, and the number of hammering times is 10 to 22 times;

[0023] Step 2, one-sided flushing: perform one-sided flushing on the hammered forging;

[0024] Step 3. Repeated flushing: carry out flushing on the corresponding surface of the forging that has undergone single-sided flushing in step 2, and repeat the operations of steps 2 and 3 for 2 to 3 times;

[0025] Step 4. Rolling: Before rolling, preheat the rolling wheel. After the temperature of the rolling wheel reaches 150-200°C, roll the forging that has undergone repeated...

specific Embodiment approach 2

[0027] Specific embodiment 2: In step 1 of this embodiment, the number of times of hammering is 15-20 times. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: In the step one described in this implementation mode, the number of hammering times is 18 times. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com