Fluid conveying pipeline surface coating removing mechanical arm

A surface coating and fluid pipeline technology, applied in the field of surface coating removal manipulators for fluid conveying pipelines, can solve the problems of time-consuming, high coating bonding strength and labor, and achieve the effect of increasing stability and cleaning thoroughly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

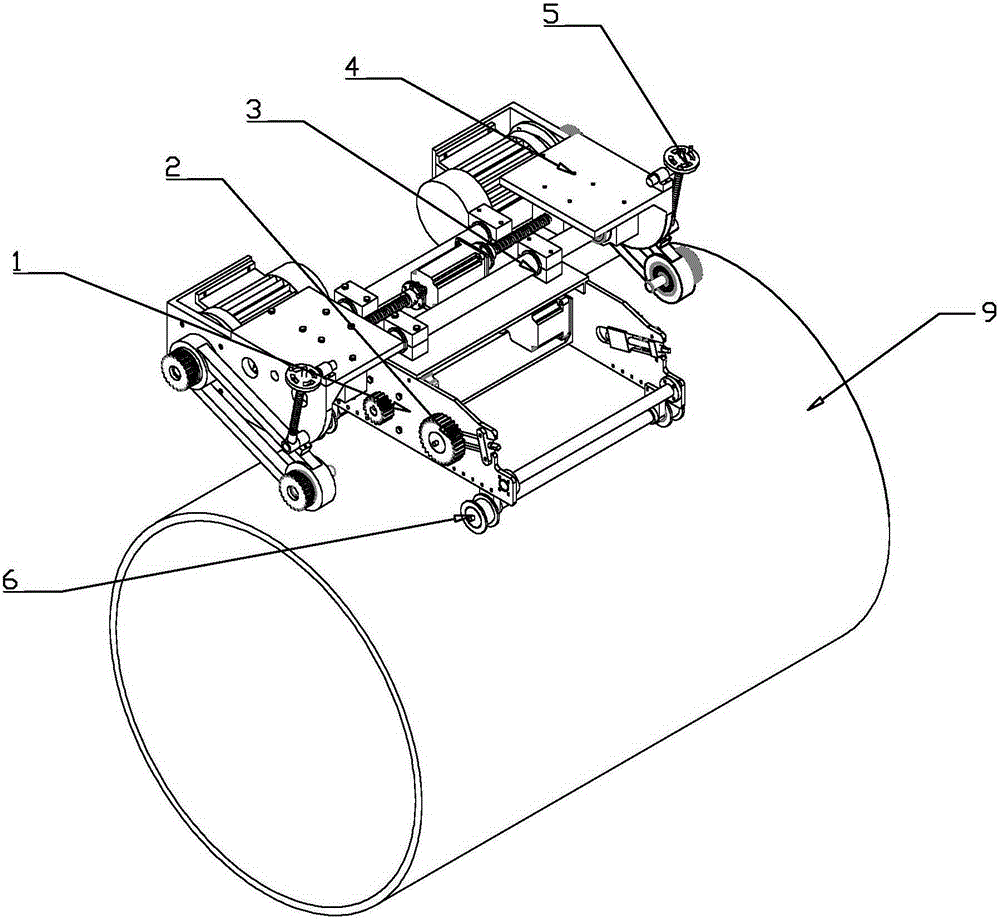

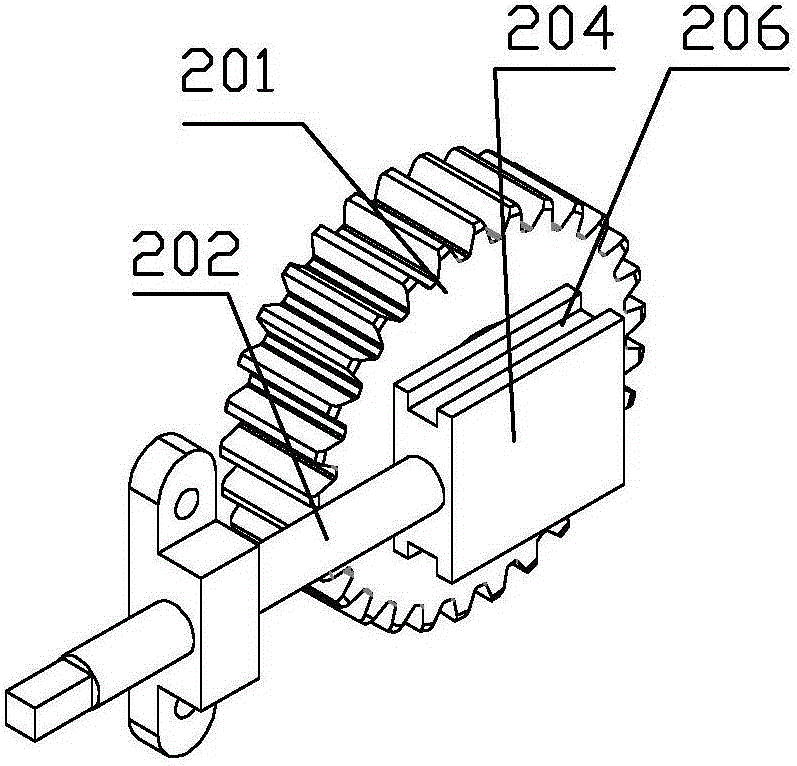

[0037] Example: such as figure 1 As shown, the present invention includes a bracket 1, a chain elastic adjustment device 2, a lateral adjustment device 3, an actuator 4, a pressure adjustment device 5 and a running mechanism 6, and the lateral adjustment device 3 is placed on the top plate 103 of the bracket 1, and the two actuators 4 is symmetrically connected to both ends of the lateral adjustment device 3, and the pressure adjustment device 5 is connected to the outside of the two actuators 4. The chain tension adjustment device 2 is set on the strip groove of the side plate 101 of the bracket, and the running mechanism 6 is connected to the side plate of the bracket. 101 on.

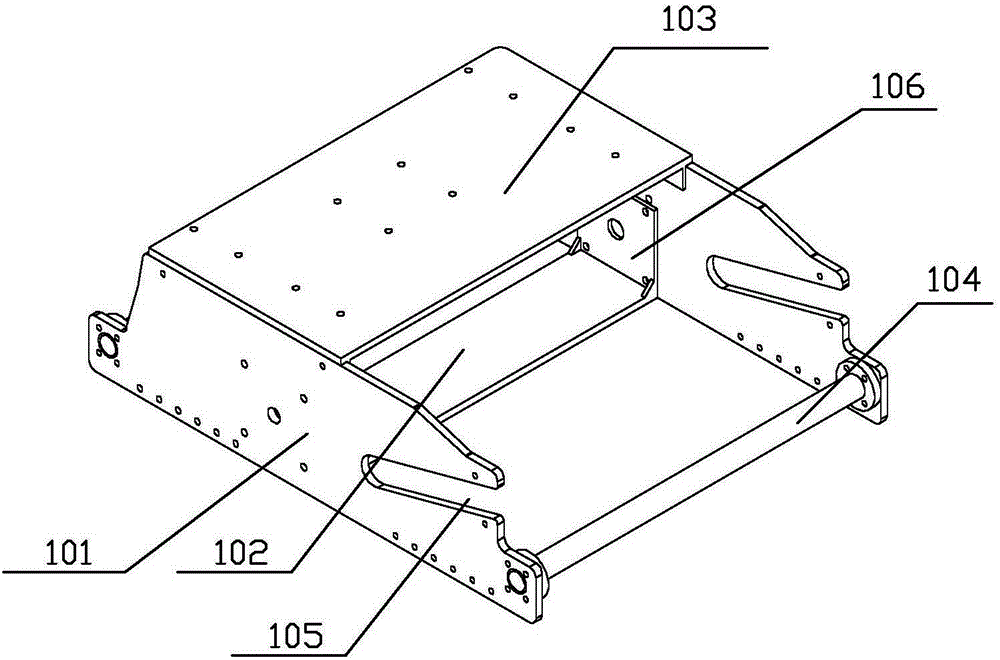

[0038] Such as figure 2 As shown, the bracket 1 includes a top plate 103, a bottom plate 102, two side plates 101 and a cylindrical bar 104, and the top and bottom ends of the two side plates 101 are respectively connected to the top plate 103 and the bottom plate 102 to form a supporting frame. E...

Embodiment 2

[0048] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the open end of the long groove 105 on the side plate in this embodiment is higher than the closed end, and the angle α between it and the horizontal plane is 20 degrees.

Embodiment 3

[0049] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the open end of the long groove 105 on the side plate in this embodiment is higher than the closed end, and the angle α between it and the horizontal plane is 25 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com