Air exhausting device

A device for generating bubbles and a technology for dispersing air, applied in the directions of dissolution, mixer, chemical instruments and methods, etc., can solve the problems of great influence, difficulty, flying out of the cylinder, etc., to improve efficiency, generate high efficiency, and avoid gas wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

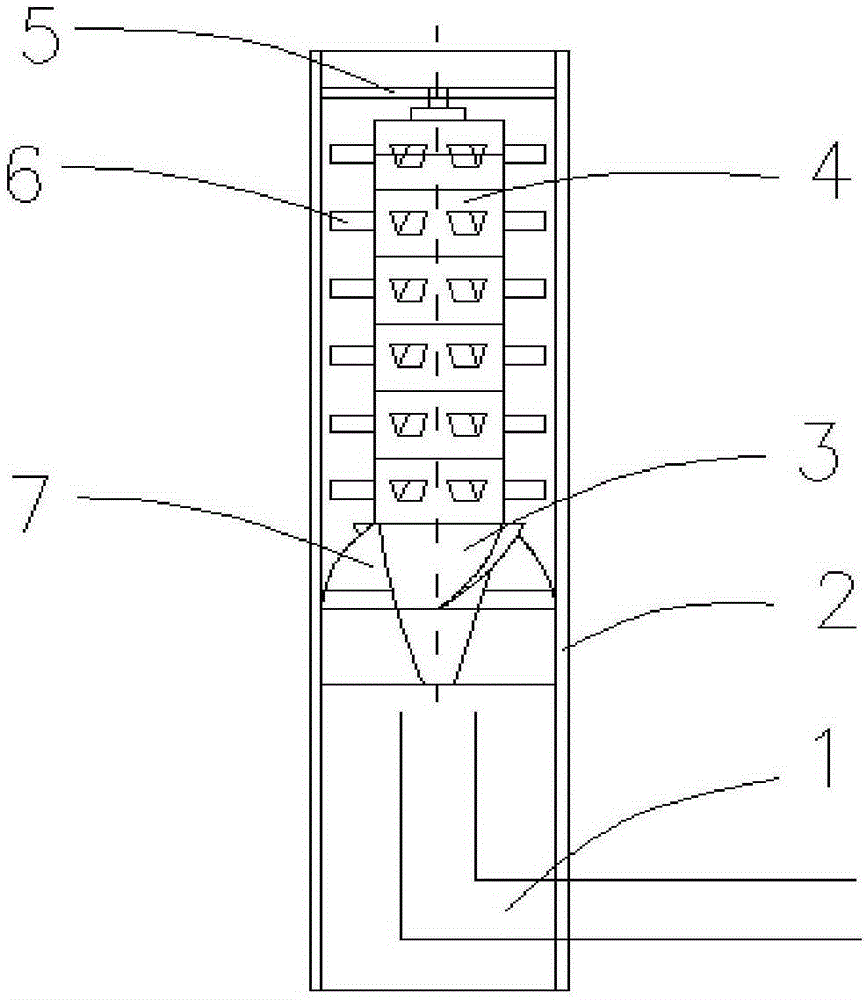

[0018] Such as figure 1 and figure 2 As shown, an air diffuser includes an air intake pipe, an outer cylinder, and an inner core disposed inside the outer cylinder, the inner core is fixedly installed in the outer cylinder and forms a relatively narrow ring-shaped three-dimensional space with the outer cylinder; The upper part of the inner core is formed by stacking six bubble generating devices up and down, and each bubble generating device is surrounded by seven protrusions horizontally in the ring-shaped three-dimensional space. The cross-section of the protrusions is an inverted triangle. The protrusions on the installed bubble generating device are staggered at a 40-degree angle in the vertical direction to form a large air channel. Due to the large air channel, the gas-liquid mixture has a fast flow rate and strong stirring force; the lower part of the inner core is an inverted Conical diversion rotating device, the surface of the diversion rotating device is equipped ...

Embodiment 2

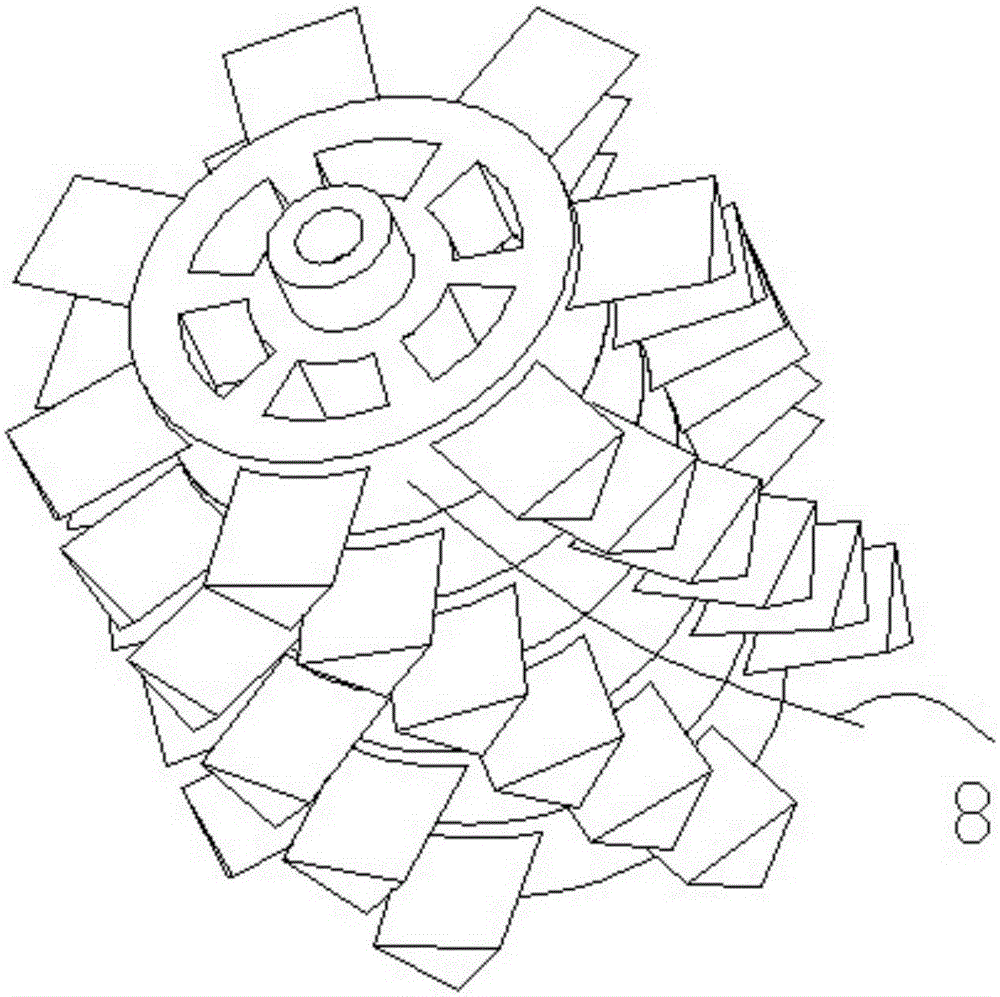

[0020] Such as image 3 As shown, on the basis of Embodiment 1, the upper part of the inner core is changed to be stacked up and down by eight bubble generating devices, and each bubble generating device is provided with eight protrusions horizontally in the ring-shaped three-dimensional space. The cross-section of the object is an inverted triangle, and the protrusions on the bubble generating devices stacked up and down are staggered with each other at an angle of 45 degrees in the vertical direction, forming a narrow air passage much smaller than that of the embodiment on the surface of the inner core. Compared with Example 1, the narrow airway is smaller than the airway, and the gas (big bubble cluster) directly flowing out of the bubble generating device from the narrow airway in this embodiment is much less than that of Example 1. Compared with Example 1 , less gas loss, and higher microbubble generation efficiency.

Embodiment 3

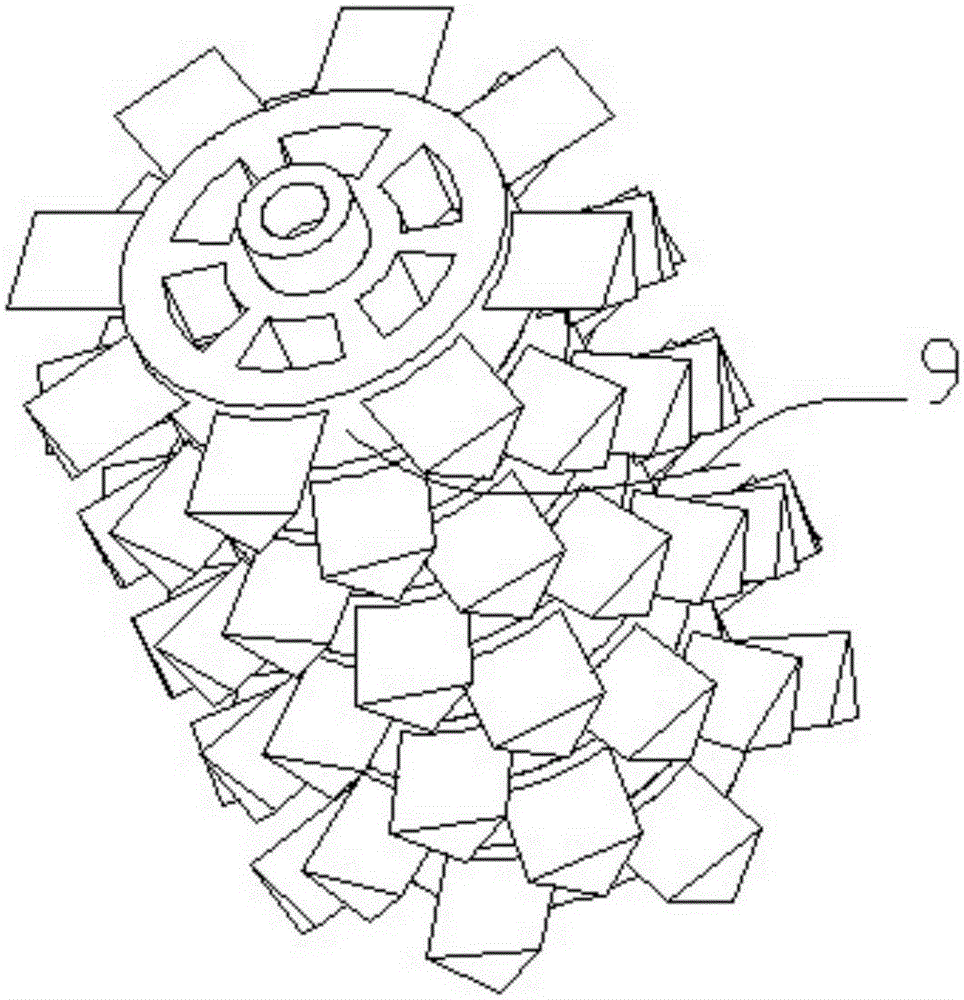

[0022] Such as Figure 4 and Figure 5 As shown, on the basis of Embodiment 1, the upper part of the inner core is replaced with ten bubble generators, and two bubble generators arranged up and down in sequence form a set of variable pressure bubble generators, each group of variable pressure bubble generators In the device, the number of protrusions around the upper air bubble generating device is greater than the number of protrusions on the lower air bubble generating device, the protrusions on the upper and lower stacked air bubble generating devices are staggered from each other, and there is no air channel on the surface of the inner core, Compared with Embodiment 1 and Embodiment 2, the air loss is less, and the generation effect of micro bubbles is better, especially outstanding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com