A high-efficiency purification device for plant extracts and a method for purifying plant extracts

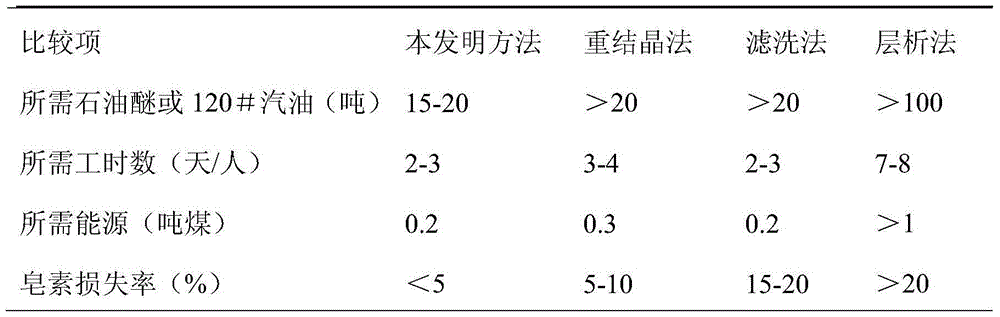

A plant extract and purification device technology, which is applied in the fields of medicinal chemical engineering and natural product purification, can solve the problems of cumbersome operation, high loss of target extract, and high cost, and achieve less loss of organic solvents, less loss of crystallization products, and lower manufacturing costs. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

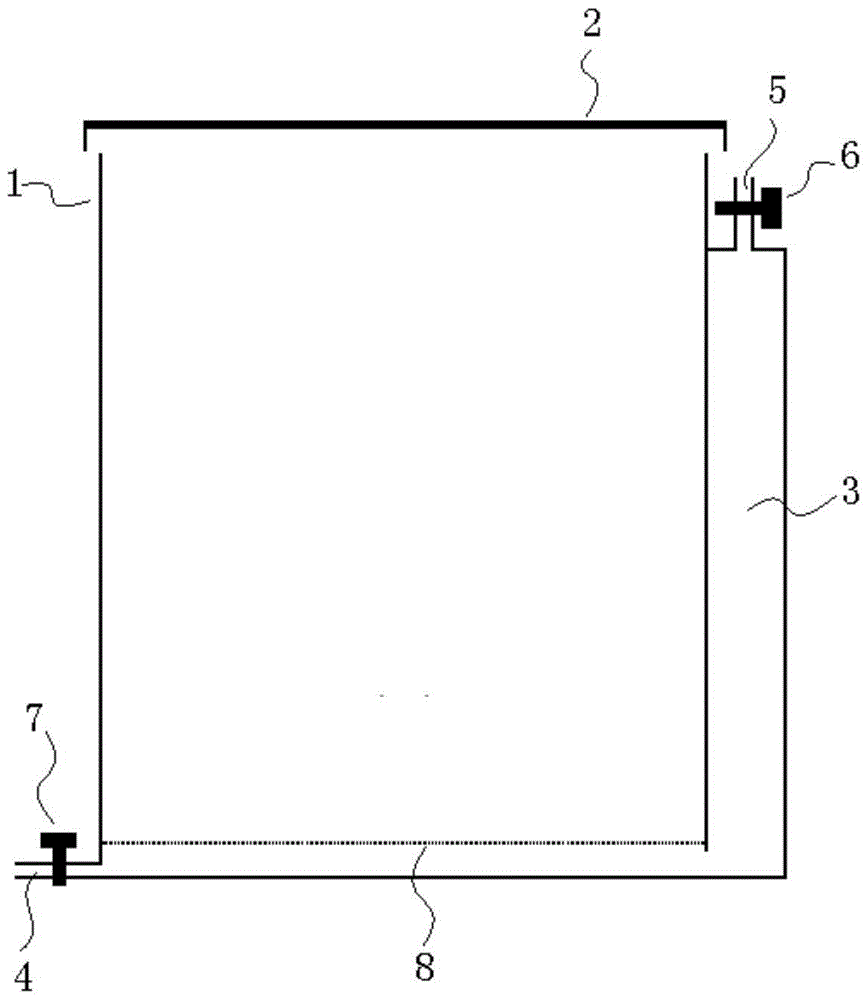

Image

Examples

Embodiment 1

[0031] A method for purifying diosgenin using the above-mentioned high-efficiency purification device for plant extracts, the steps:

[0032] 1) Open the lid of the purification tank first, inject the hot No. 120 gasoline or petroleum ether concentrate obtained after extracting diosgenin into the tank body of the purification tank, then close the lid of the purification tank tightly, and place the tank body of the purification tank at 0-15 Cool down in a low-temperature environment until the diosgenin in the concentrated solution is completely precipitated and crystallized, then open the outlet valve, draw out the remaining solution after crystallization, and then continue to inject the above-mentioned hot concentrated solution into the purification tank, continue to cool down, Precipitation and crystallization are repeated until the accumulated volume of diosgenin crystals in the purification tank is more than 2 / 3 of the volume of the purification tank.

[0033] 2) Close the ...

Embodiment 2

[0042] A method for purifying dihydromyricetin using the high-efficiency purification device of the above-mentioned plant extract, its steps:

[0043] 1) Open the cover of the purification tank first, inject cold water at 0-10 degrees Celsius into the tank body of the purification tank, and then slowly inject the hot ethanol concentrate obtained after extracting dihydromyricetin into the tank body of the purification tank, so that the ethanol in the purification tank The final concentration is below 20%. Close the lid of the purification tank, let the mixed liquid in the purification tank cool down until the dihydromyricetin in the mixed liquid is completely precipitated and crystallized, then open the outlet valve, draw out the remaining solution after crystallization, and then Continue to inject hot ethanol concentrate into the tank body of the purification tank, continue to cool down, precipitate and crystallize, and repeat this until the accumulated volume of dihydromyricet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com