Multi-station full-automatic shoe sole sandblast polishing glue-spraying and drying disk machine

A fully automatic, multi-station technology, applied to shoe soles, shoemaking machinery, abrasive jet machine tools, etc., can solve problems such as non-compliance with environmental protection requirements, fire hazards, and serious dust pollution, so as to improve processing efficiency and processing quality , Reduce labor intensity and technical requirements, and the effect of large grinding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

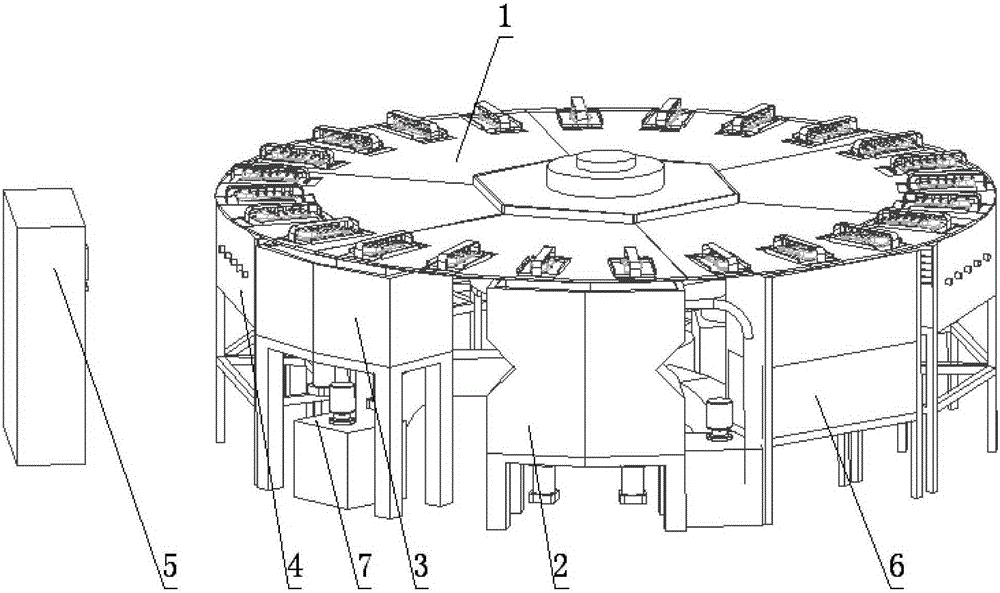

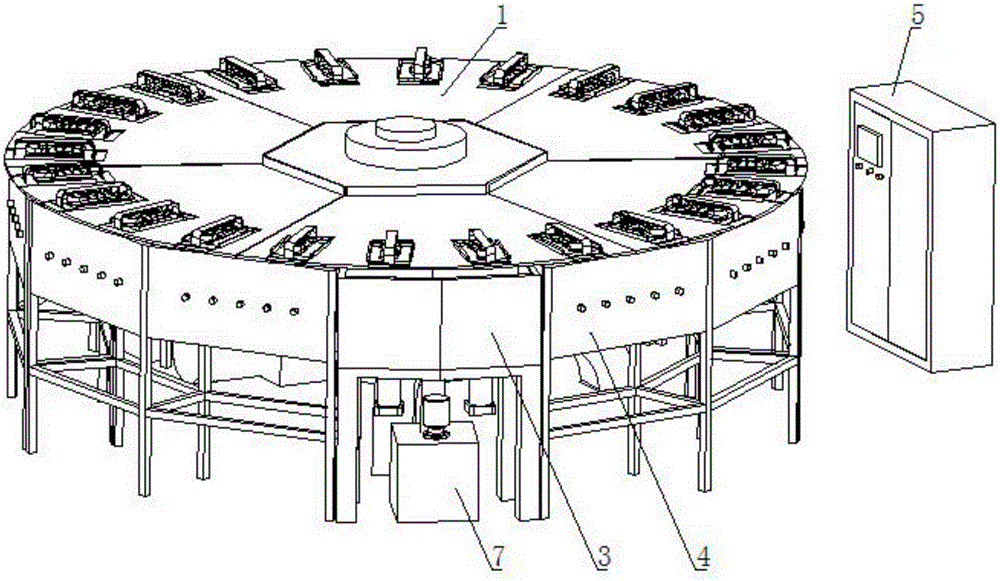

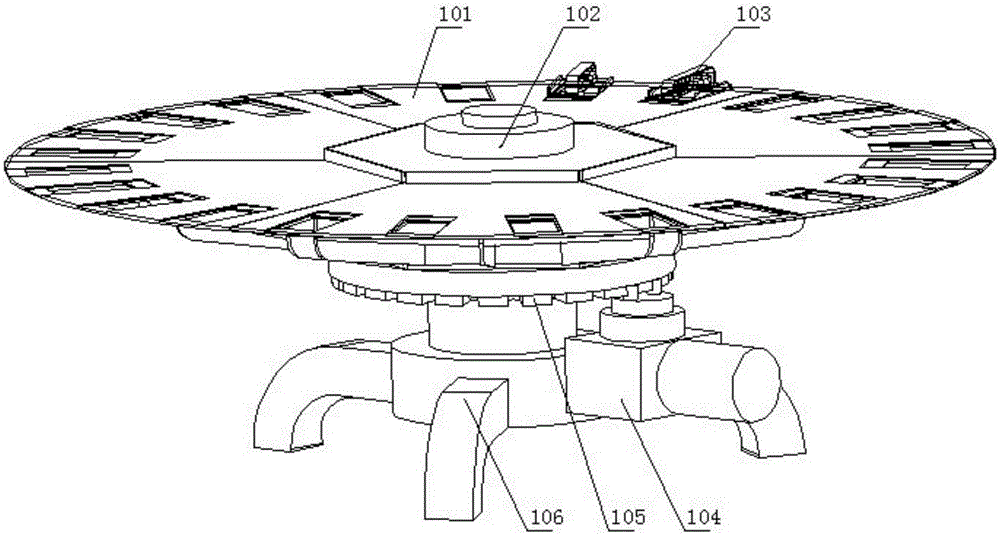

[0042] A multi-station fully automatic shoe sole sandblasting, polishing, glue spraying and drying disc machine, comprising a turntable mechanism 1, a refrigeration mechanism 6, a polishing mechanism 2, a glue spraying mechanism 3, a drying mechanism 4, and an electric control cabinet 5, the outer periphery of the turntable mechanism is A plurality of sole fixing brackets 103 are evenly distributed in the radial direction, and a refrigeration box, a fluffing mechanism, a glue spraying mechanism and a plurality of drying mechanisms are installed in the ring-shaped lower part of the corresponding turntable mechanism below the plurality of shoe sole fixing brackets. mechanism, raising mechanism, glue spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com