Drying machine and work method thereof

A drying machine and drying chamber technology, applied in food science, food preservation, application, etc., can solve problems that affect the smooth progress of the drying process, and achieve the effect of overcoming technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

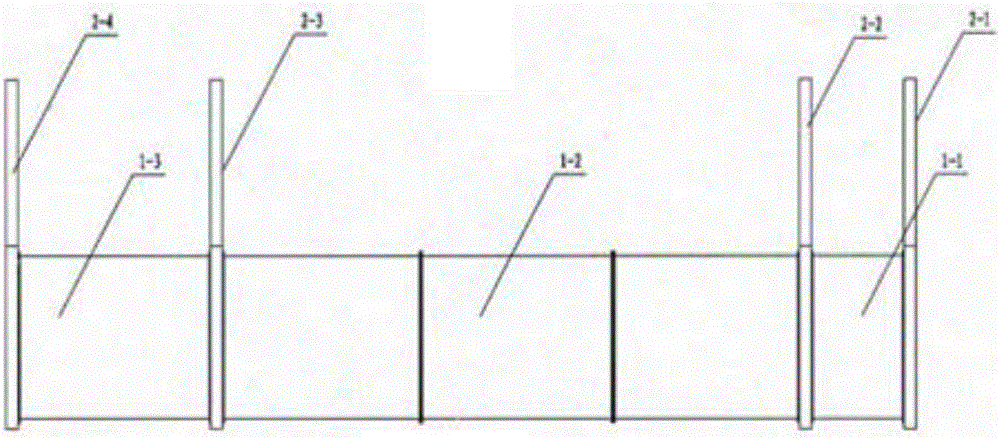

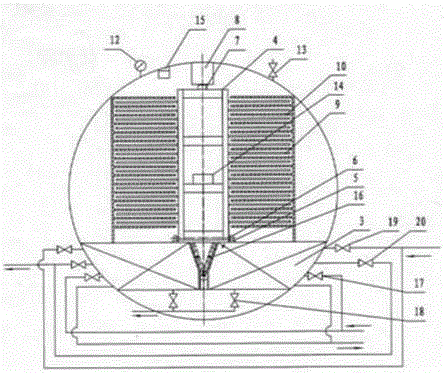

[0053] In Example 1, the vacuum precooling and drying chamber 1-1, the far-infrared drying chamber 1-2 and the microwave drying chamber 1-3 are respectively equipped with a vacuum system, a heating system, a condensation system and a loading system.

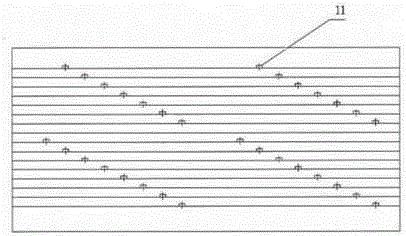

[0054] (1) Open the first isolation valve 2-1, push the material trolley 4-1 with the material to be dried into the vacuum precooling and drying chamber 1-1, the roller 6 enters the guide rail 5, the nylon rack 7 and the gear of the trolley driving device 8 engagement, the feed tray on the feeding cart 4-1 is just inserted between the far-infrared radiation plates 10.

[0055] (2) Start the command switch trigger, close the first isolation valve 2-1, the command switch is triggered, and the control system of the vacuum precooling and drying chamber 1-1 enters the following procedure:

[0056] a Open the condensing coil control valve 17 to keep the temperature of the cold trap at about -15°C;

[0057]b Open the control valve 20 o...

Embodiment 2

[0092] Embodiment 2: the vacuum pre-cooling drying bin 1-1 is provided with a vacuum system, a loading system and a condensation system, and the far-infrared drying bin 1-2 and the microwave drying bin 1-3 are respectively provided with a vacuum system, a loading In addition to the material system and the condensation system, there are also heating systems.

[0093] (1) Open the first isolation valve 2-1, push the material trolley 4-1 with the material to be dried into the vacuum precooling and drying chamber 1-1, the roller 6 enters the guide rail 5, the nylon rack 7 and the gear of the trolley driving device 8 meshes.

[0094] (2) Start the command switch trigger, close the first isolation valve 2-1, the command switch is triggered, and the control system of the vacuum precooling and drying chamber 1-1 enters the following procedure:

[0095] a Open the condensing coil control valve 17 to keep the temperature of the cold trap at about -15°C;

[0096] b Open the control val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com