Process for improving quality of black tea

A process and technology for black tea, which is applied in the field of technology to improve the quality of black tea, can solve the problems of the quality of flowers not meeting the product requirements, being easily broken, and the time of shaking is elongated, so as to improve the taste and taste, beautiful appearance, and reduce the degree of fragmentation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

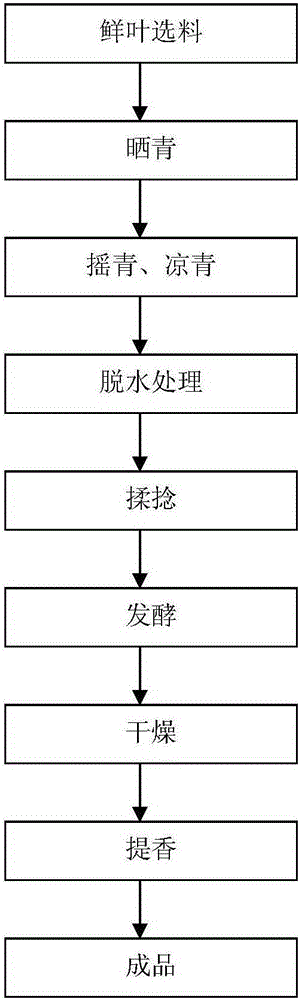

Image

Examples

Embodiment 1

[0032] Embodiment 1 improves the technique of flower fragrance Gongfu black tea quality

[0033] 1. Raw materials of fresh leaves: use 1 bud and 2 leaves or pair of leaves with the same tenderness.

[0034] 2. Drying green: spread the collected fresh leaves thinly, spread them in the withering tank at room temperature, the thickness of the spread leaves is 5-6cm, spread the time for 1h, and then put them under 25000Lux light intensity (or take them outdoors before 10 am or After 5 o'clock in the afternoon) to dry in the sun, the drying time is about 15 minutes, turn it over 1-2 times in the middle, the leaf temperature reaches about 40°C (measured by spot temperature), collect and spread it indoors for 1 hour.

[0035] 3. Shake the green: shake the green leaves 3 times after drying the green, the rotating speed is 70r / s, and the shaking time is 1, 2, and 3min respectively. Cool the greens in the withering room, cool the greens for 2 hours after the first 2 shakes, and cool th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com