Normal-temperature set yogurt and preparation method thereof

A technology of coagulation and yogurt at room temperature, applied in milk preparations, dairy products, applications, etc., can solve problems such as extending the shelf life, short shelf life of low-temperature drinking yogurt, expanding the sales radius of coagulated yogurt, etc., to achieve the effect of extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

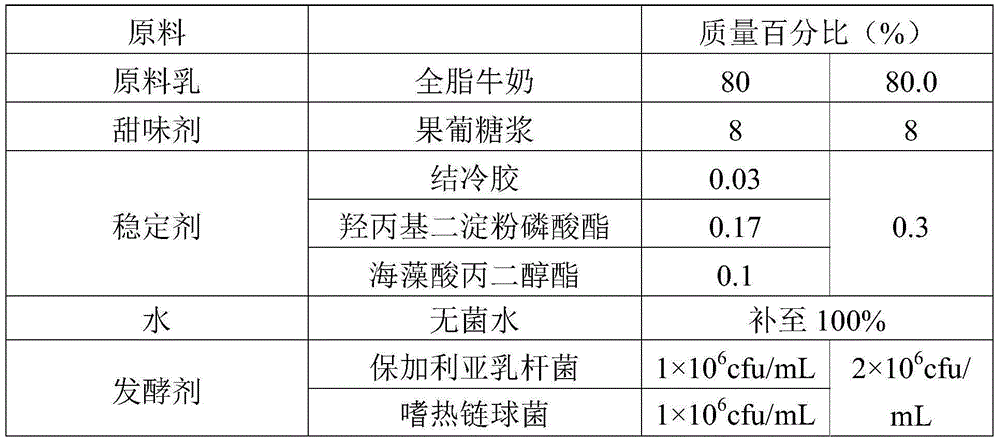

[0038] The raw materials are shown in Table 1.

[0039] Table 1

[0040]

[0041] (1) According to raw milk, sweetener, stabilizer and water, prepare ingredients, mix and stir at 40°C for 15 minutes and homogenize, the first-level homogenization pressure is 15Mpa, the homogenization temperature is 54°C, and then sterilized at 90°C for 5 minutes Cool to 4°C to obtain a mixed feed solution;

[0042] (2) Add starter in the mixed liquid, wherein Lactobacillus bulgaricus 1×10 6 cfu / mL, Streptococcus thermophilus 1×10 6 cfu / mL, using paper cup filling, the filling volume accounts for 95% of the packaging volume,

[0043] (3) Fermentation was carried out at 37°C after filling, and the acidity reached 70°T after 11 hours, the fermentation was stopped, cooled to 15°C, and treated at 300Mpa pressure for 3 minutes at 15°C, to obtain ultra-high pressure treated solidified yogurt. Store at room temperature.

[0044] The total number of bacterial colonies, mold, yeast, Escherichia c...

Embodiment 2

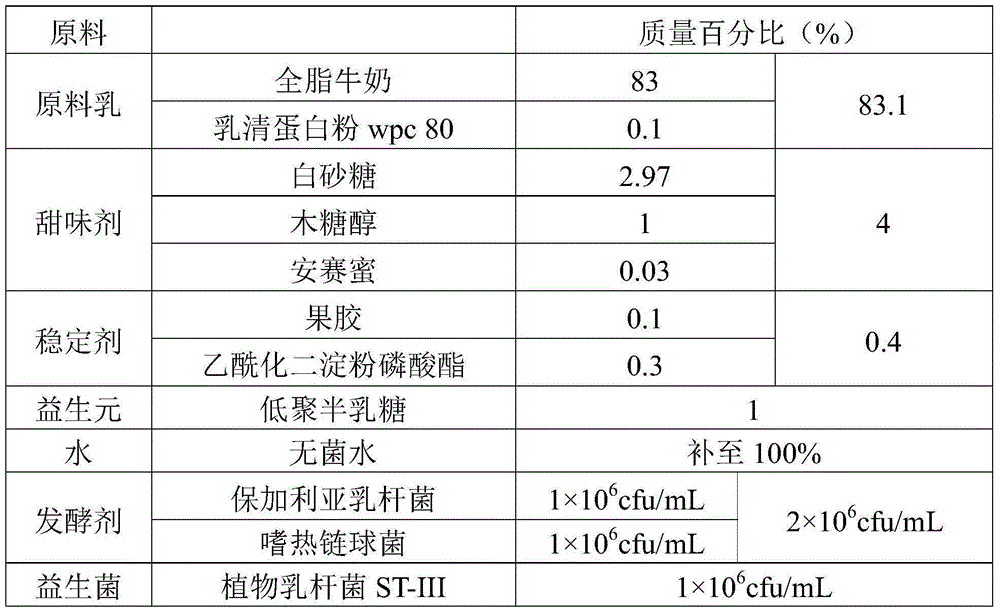

[0046] The raw materials are shown in Table 2.

[0047] Table 2

[0048]

[0049] (1) Homogenize the raw milk, sweetener, stabilizer, prebiotics and water after mixing and stirring at 42°C for 17 minutes, the primary homogenization pressure is 15Mpa, the secondary homogenization pressure is 2Mpa, and the homogenization temperature is 56 °C, then sterilized at 91 °C for 5.5 minutes and then cooled to 28 °C to obtain a mixed feed solution;

[0050] (2) Add starter and probiotics to the mixed liquid, and fill it in a Tetra Pak TT tank with a filling volume of 95%,

[0051] (3) Fermentation was carried out at 38°C, the acidity reached 73°T after 10 hours, the fermentation was stopped, cooled to 17°C, homogenized, and treated at 350Mpa at 17°C for 3.5 minutes to obtain ultra-high pressure treated solidified yoghurt. Store at room temperature.

[0052] The total number of bacterial colonies, mold, yeast, Escherichia coli, and pathogenic bacteria were detected at the time of pr...

Embodiment 3

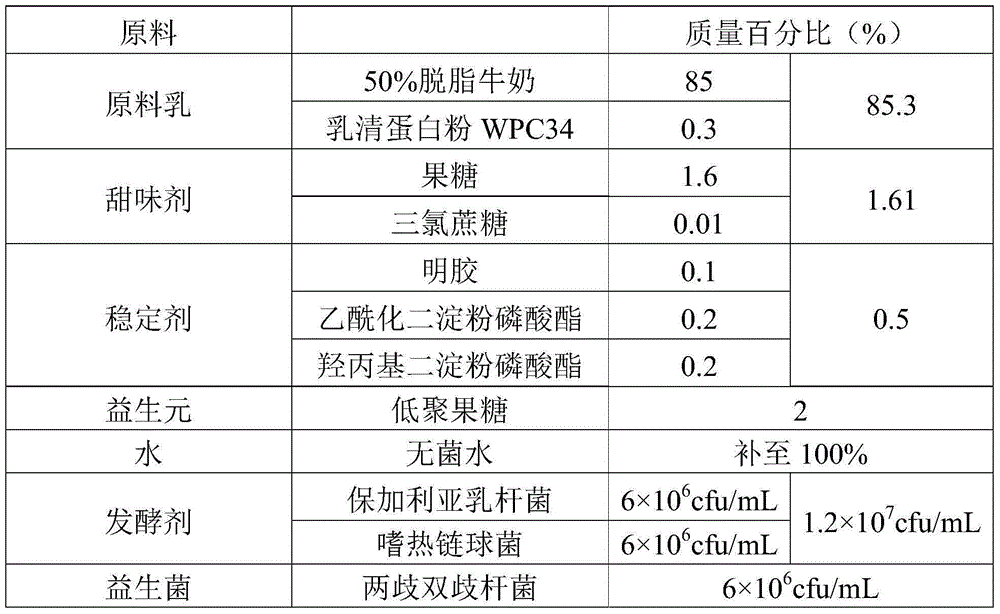

[0054] The raw materials are shown in Table 3.

[0055] table 3

[0056]

[0057] (1) Mix the raw milk, sweetener, stabilizer, prebiotics and water, mix and stir at 43°C for 20min, homogenize, the primary homogenization pressure is 17Mpa, the homogenization temperature is 58°C, and then sterilize at 92°C for 6min After cooling to 37 ° C, to obtain a mixed liquid

[0058] (2) Add starter and probiotics to the mixed liquid, and fill it in a PET prefabricated bottle with a filling volume of 96%,

[0059] (3) Fermentation was carried out at 39°C, the acidity reached 74°T after 9.6 hours, the fermentation was stopped, and then it was treated at 19°C under 400Mpa for 4 minutes under the environment of 19°C to obtain ultra-high pressure treatment coagulation type yogurt.

[0060] The total number of bacterial colonies, mold, yeast, Escherichia coli, and pathogenic bacteria were detected at the time of production and 4 months, and they were all undetected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com