Alkaline zinc secondary battery and preparation method thereof

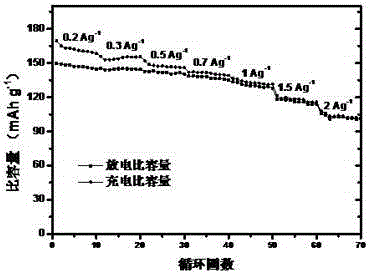

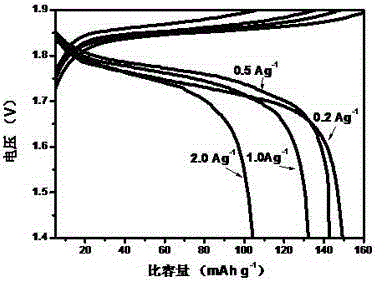

A secondary battery, alkaline technology, applied in the field of electrochemistry, can solve the problems of low conductivity and reaction platform, low energy density, poor rate performance, etc., and achieve the effect of low price, high energy density and excellent cycle rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of sodium ion battery, comprising the following steps:

[0026] Positive electrode preparation: the positive electrode active material NiS 2 , the conductive agent acetylene black and the binder polytetrafluoroethylene are mixed according to the mass ratio of 8:1:1, and then diluted with water to prepare a positive electrode slurry, which is coated on the stainless steel current collector, dried at 120°C, and compacted. Make a positive pole piece.

[0027] Negative electrode preparation: the negative electrode material Zn 0.1 mn 0.9 , The binder polytetrafluoroethylene is mixed according to the mass ratio of 9:1, and then diluted with water to prepare a negative electrode slurry, which is coated on a stainless steel current collector, dried at 120°C, and compacted to make a positive electrode sheet.

[0028] Preparation of aqueous electrolyte:

[0029] Add 15mL deionized water to a 20mL reagent bottle, add 0.1mol / LKOH+5mmol / LZn(Ac) 2 , stirred ...

Embodiment 2

[0037] Positive electrode preparation: the positive electrode active material NiCo 2 S 4 , the conductive agent acetylene black and the binder sodium alginate are mixed according to the mass ratio of 8:1:1, and then diluted with water to prepare a positive electrode slurry, which is coated on the carbon paper collector, dried at 120 °C, and compacted. Make a positive pole piece.

[0038] Negative electrode preparation: the negative electrode material Zn 0.5 mn 0.5 , The binder polytetrafluoroethylene is mixed according to the mass ratio of 9:1, and then diluted with water to prepare a negative electrode slurry, which is coated on a stainless steel current collector, dried at 120°C, and compacted to make a positive electrode sheet.

[0039] Preparation of aqueous electrolyte:

[0040] Add 15mL deionized water to a 20mL reagent bottle, add 1mol / LKOH+20mmol / LZn(NO 3 ) 2 , stirred into a transparent and homogeneous solution.

[0041] A kind of alkaline zinc secondary batter...

Embodiment 3

[0048] Positive electrode preparation: the positive electrode active material FeS 2 , the conductive agent acetylene black and the binder sodium carboxymethylcellulose are mixed according to the mass ratio of 8:1:1, and then diluted with water to prepare a positive electrode slurry, which is coated on the carbon cloth current collector and dried at 120°C. Compacted to make a positive pole piece.

[0049] Negative electrode preparation: the negative electrode material Zn 0.9 mn 0.1 , The binder polytetrafluoroethylene is mixed according to the mass ratio of 9:1, and then diluted with water to prepare a negative electrode slurry, which is coated on a stainless steel current collector, dried at 120°C, and compacted to make a positive electrode sheet.

[0050] Preparation of aqueous electrolyte:

[0051] Add 15mL deionized water to the 20mL reagent bottle, add 2mol / LKOH+50mmol / LZnSO 4 , stirred into a transparent and homogeneous solution.

[0052] A kind of alkaline zinc second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com