Gradient composite copper-chromium contact material and preparation method thereof

A copper-chromium contact and gradient technology, which is applied in the field of gradient composite copper-chromium contact materials and their preparation, can solve the problems of surface cracks, material falling off and switch, failure, etc. of copper-chromium materials, so as to improve heat dissipation performance and improve dielectric recovery. performance, effect of reducing loop resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

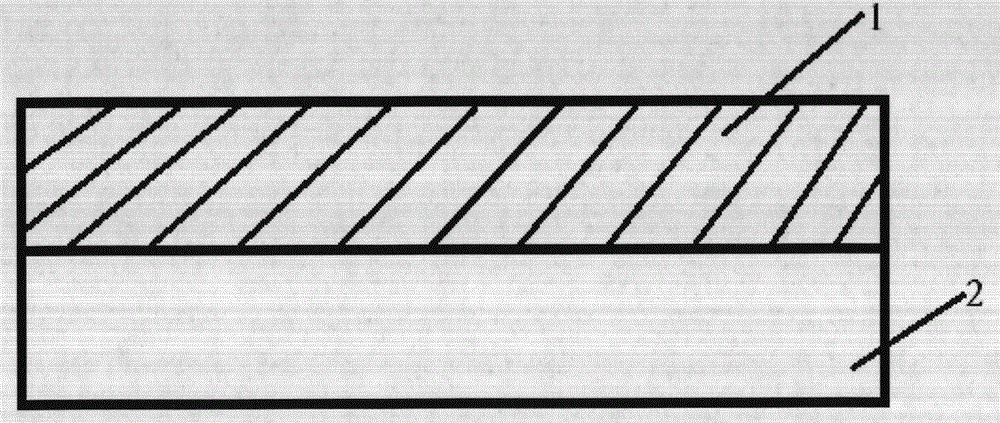

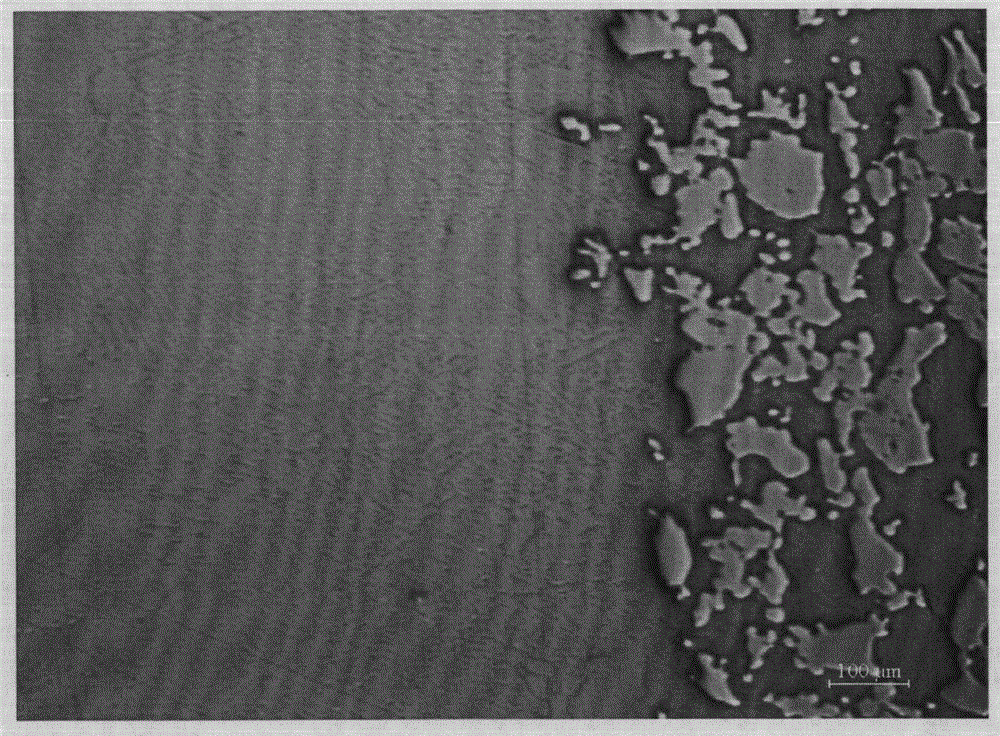

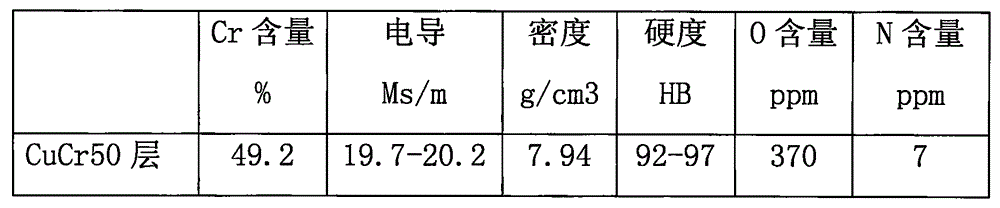

[0040] A gradient composite copper-chromium contact material, which is mainly composed of CuCr50 layer and CuCr1 layer, the composition of CuCr50 layer is: Cr content 45-55%, Cu balance; CuCr1 layer composition is: Cr The content is 0.6-2.1%, and the balance of Cu; the raw materials are respectively 65-200 micron Cr powder and 100 micron Cu powder.

[0041]The chromium powder is electrolytic chromium powder or thermite reduced chromium powder, and the copper powder is electrolytic copper powder or atomized copper powder.

[0042] The purity of the chromium powder is 99.3%-99.98%.

[0043] In addition, the preparation method of the gradient composite copper-chromium contact material includes the following steps:

[0044] (1) Raw material selection

[0045] Choose 65-200 micron chromium powder and 100 micron copper powder;

[0046] (2) mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com