Scheduling control method for wafer loading device of semiconductor heat treatment equipment, and system

A technology of heat treatment equipment and scheduling control, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve problems such as the number of uses and cumulative film thickness limitations, and cannot be used multiple times, to ensure machine safety and process quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

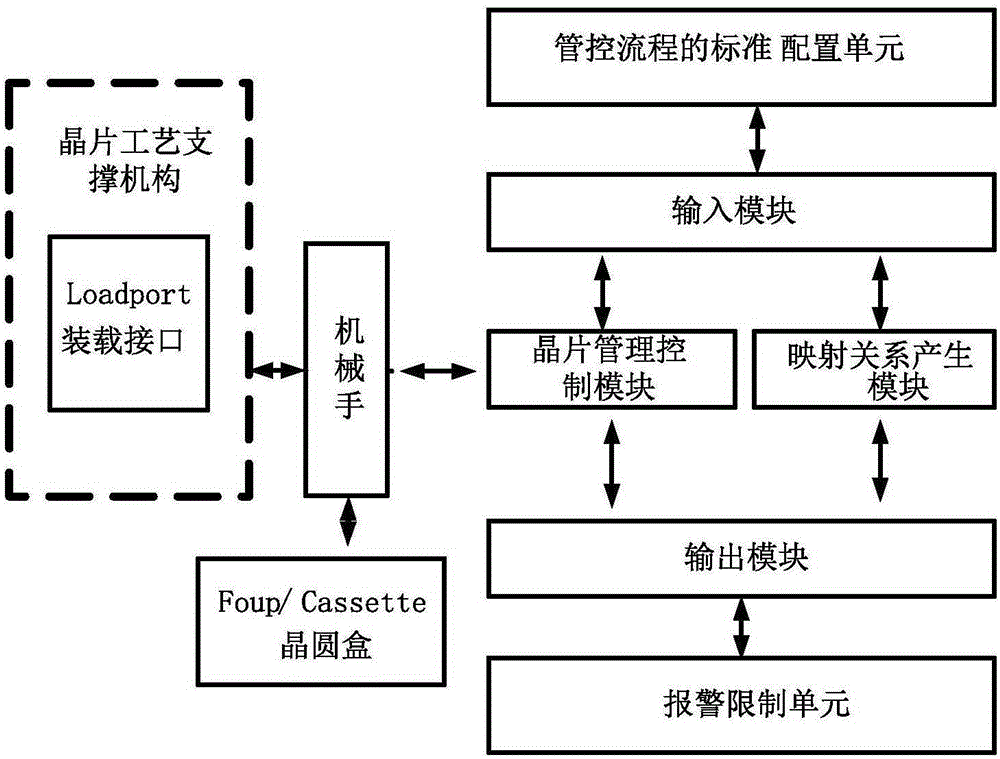

[0046] Attached below Figure 1-5 , the specific embodiment of the present invention will be further described in detail.

[0047] It should be noted that due to the structural characteristics of semiconductor heat treatment equipment, combined with actual process requirements, it needs to use multiple types of Wafer (Monitor, Product, Dummy, ExtraDummy, etc.) to perform the process at the same time. In the following embodiments, Wafer represents a wafer, Foup and Cassette represent a wafer cassette, LoadPort represents an interface of a wafer process support mechanism on a semiconductor device, and Slot represents a placement position of a wafer in the wafer cassette.

[0048] The scheduling control system of the wafer loading device of the semiconductor heat treatment equipment of the present invention can be realized by hardware or software, preferably, it can be realized by combining software and hardware. In order to be compatible with other control frameworks of semicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com