High-power double-clad optical fiber cladding light stripper device and manufacturing method

A double-clad optical fiber and cladding optical stripping technology, which is applied in the field of optoelectronics, can solve the problems of light leakage point stripper burning, difficulty in mass production, and difficult removal of light with low numerical aperture, so as to avoid the optical gel from being burned out , reduced power density, high stripping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

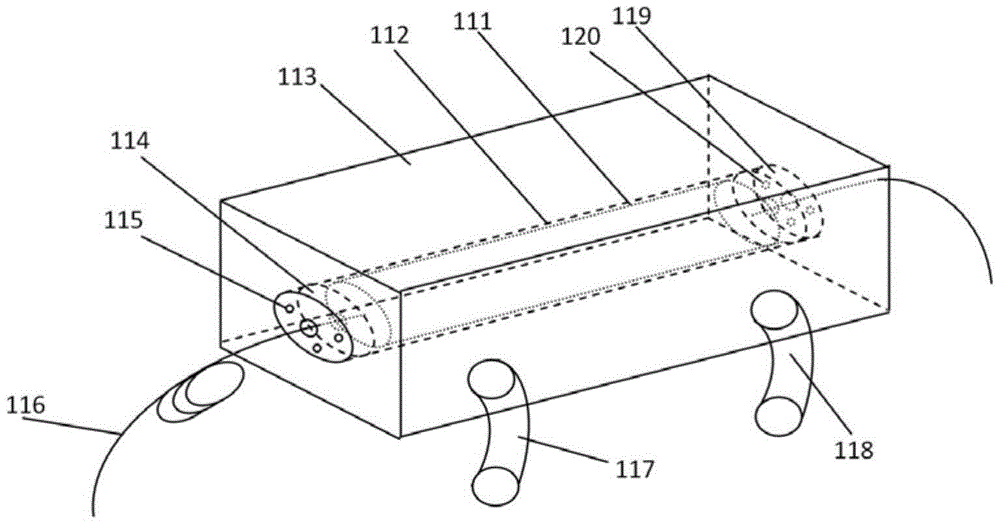

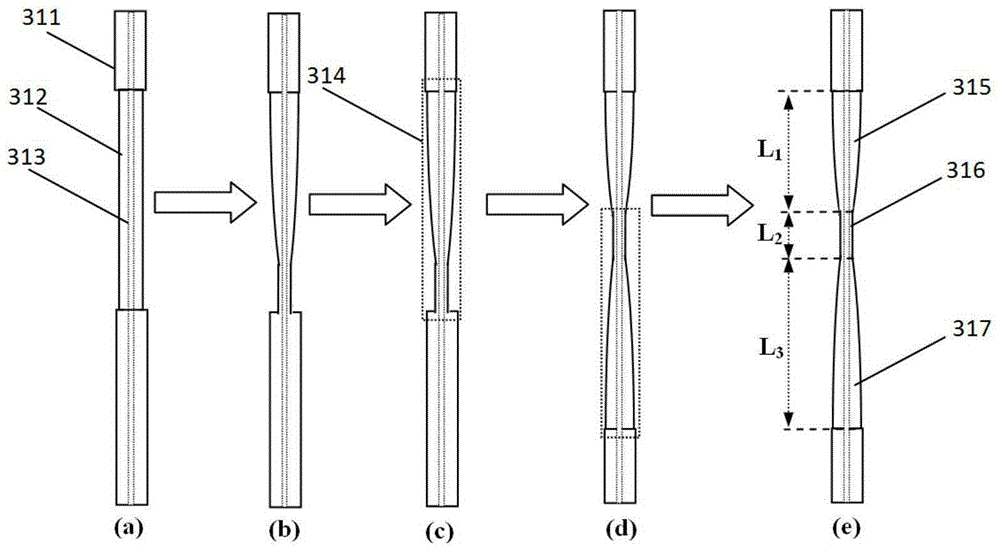

[0032] A patented high-power optical fiber cladding power stripper device (201510024289.5) makes the optical fiber into a stepped structure, which can strip low-order modes and light leakage evenly dispersed near multiple stepped structures, and uses a three-layer waveguide structure to leak light out of the optical fiber Uniform export solves the problem that the light leaked from the fiber cladding cannot be quickly dispersed. This structure is simple to manufacture, but when the fiber is thick, the middle of the three-layer waveguide structure is an adhesive layer, which is difficult to fix when the fiber is made, and the upper and lower layers of light-transmitting materials are difficult. Balance increases the difficulty of production.

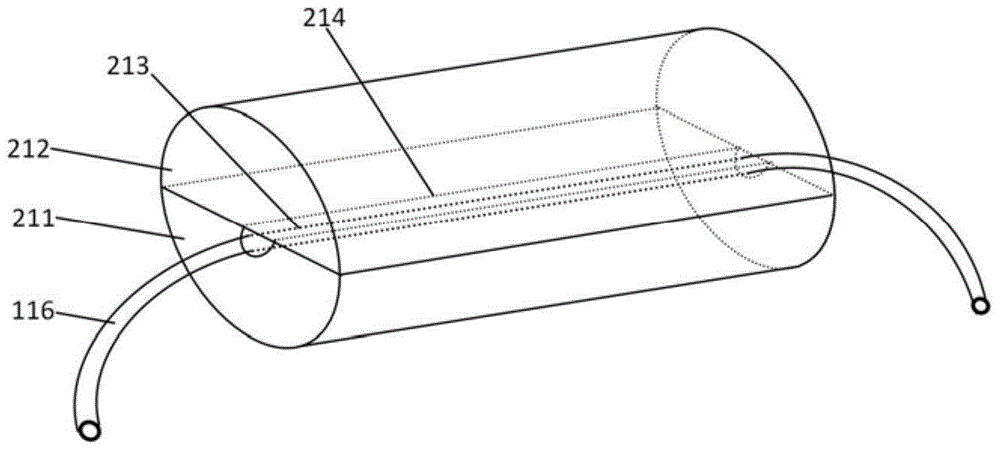

[0033] When stripping higher-power optical fibers, the tapered structure is more advantageous in terms of uniform light leakage. In addition, the use of a cylindrical waveguide structure can further increase the body-to-surface ratio, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com